Energy-efficient Motor Market SIZE AND SHARE ANALYSIS - GROWTH TRENDS AND FORECASTS (2024 - 2031)

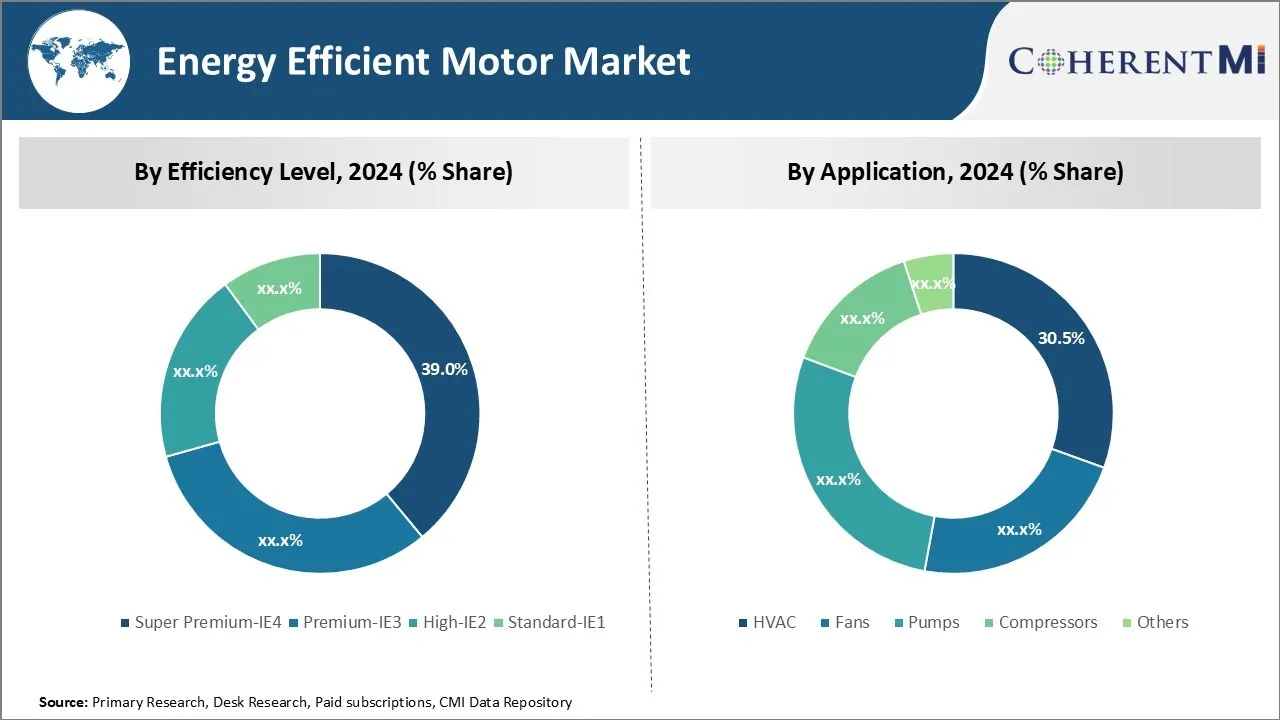

Energy-efficient Motor Market is segmented By Efficiency Level (Super Premium-IE4, Premium-IE3, High-IE2, Standard-IE1), By Application (HVAC, Fans, P....

Energy-efficient Motor Market Size

Market Size in USD Bn

CAGR9.6%

| Study Period | 2024 - 2031 |

| Base Year of Estimation | 2023 |

| CAGR | 9.6% |

| Market Concentration | High |

| Major Players | Johnson Controls Inc., AG Regal, General Electric Company, Bosch Rexroth, Schneider Electric SE and Among Others. |

please let us know !

Energy-efficient Motor Market Analysis

The energy-efficient motor market is estimated to be valued at USD 60.63 Bn in 2024 and is expected to reach USD 115.41 Bn by 2031, growing at a compound annual growth rate (CAGR) of 9.6% from 2024 to 2031. The energy-efficient motor market is witnessing positive trends such as growing industrial automation and stringent government regulations mandating efficient motors.

Energy-efficient Motor Market Trends

Market Driver - Lower Life Cycle Costs than Traditional Motors, Significantly Reducing Operating Expenses

One of the major drivers spurring the growth of energy-efficient motor market is the lower life cycle costs associated with it as compared to traditional motors. Energy-efficient motors have significantly higher efficiency levels which translates to lower operating expenses for end users over the lifespan of the motor.

Energy-efficient motors require lesser energy to produce the same amount of work which directly brings down energy bills. Moreover, they also generate less heat and have longer operational lifespan. As a result, overall operating and maintenance costs associated with energy-efficient motors are much lower than traditional ones.

Significant savings in electricity bills and operational costs more than offset the higher initial price tag of efficient motors. Various studies have shown energy-efficient motors can reduce lifecycle costs up to 35% in some applications. With rising electricity prices across the globe, the operating expenses savings are set to increase further thereby strengthening the economics case for energy-efficient motors. This will prove to be an important driver for growth of the energy-efficient motor market.

Market Driver - Increasing Adoption of Energy-efficient Motors in the Industrial Sector

Government regulations and policies mandating higher energy efficiency standards is another key driver fueling the energy-efficient motor market globally. Major industrialized economies have implemented stringent regulations around motor efficiency as part of their nationwide efforts to curb energy consumption and reduce carbon footprint.

These regulations have compelled industries across sectors reliant on motor-driven equipment to consciously shift towards purchasing of higher efficiency motors. In a bid to remain compliant and cut energy costs, industries are proactively replacing aging motors with energy-efficient alternatives. Regulations also mandate periodic efficiency monitoring of in-use motor population which has heightened replacement needs. Government initiatives such as financial incentives for each unit of efficient motor adoption further strengthen the business case.

Stringency of standards is only expected to ratchet up in the coming years keeping in line with international commitments on carbon reduction. Concerted regulatory push by authorities worldwide hence remains instrumental in advancing widespread replacement of conventional motors with next-gen efficient motors across industrial landscape.

Market Challenge - High Initial Investment Costs Due to Premium Components

One of the key challenges faced by the energy-efficient motor market is the high initial investment costs associated with these motors compared to traditional motors.

Energy-efficient motors use premium electronic components and advanced magnetic materials to achieve higher levels of efficiency. These components such as rare earth permanent magnets, and state of the art power electronics and control systems make the production of energy-efficient motors a complex and expensive process. The manufacturing costs are significantly higher compared to conventional design motors.

Moreover, the pricing of critical raw materials fluctuates constantly making business operations risky. The payback period on the additional investment in efficient technologies is still long for most industrial applications. Many potential customers are hesitant to make the switch due to the higher upfront capital outlay required.

This cost barrier needs to be addressed through innovative financing options and attractive rebate schemes to help drive greater adoption of these motors across different industry verticals.

Market Opportunity - Growth in Robotics and Automation Driving the Need for Energy-efficient Motors

One of the major opportunities for the energy-efficient motor market is the rising demand from the robotics and industrial automation sectors. Robots are being deployed extensively across various manufacturing facilities to automate production processes and improve operational efficiencies. Most industrial robots and automation equipment rely on electric motors to function.

More companies in the energy-efficient motor market are automating their operations to stay competitive. Consequently, the demand for intelligent motion control systems powered by energy-efficient motors is also growing tremendously.

Energy-efficient motors offer significant advantages to robotics equipment manufacturers as they help reduce energy consumption as well as cooling and maintenance costs of automated machinery over time. The reliability and longer operational life of efficient motors also decreases downtime.

Robotics and automation providers are thus increasingly integrating high performance yet low energy usage motors within their product lines. This emerging sector will be a key driver of future revenues for players in the energy-efficient motor market.

Key winning strategies adopted by key players of Energy-efficient Motor Market

One of the most successful strategies adopted by leading players like ABB, Siemens, and Rockwell Automation has been investing heavily in research and development to produce innovative and cutting-edge energy-efficient motor technologies. For example, between 2010-2015, ABB invested over $3 billion in R&D and introduced its newly developed IE4 (Super Premium Efficiency) motors that exceed IE3 efficiency levels by 10-20%. This helped ABB gain significant share in the energy-efficient motor market share, especially in the industrial segment.

Another strategic move by players like Nidec and WEG has been focusing on the developing Asian markets through acquisitions and partnerships with local players. For instance, in 2018, Nidec acquired Emerson's motor business in China to strengthen its presence in the critical Chinese energy-efficient motor market. Similarly, WEG entered partnerships with Indian firms to manufacture energy-efficient motors locally as per Indian needs and standards. This aligns with 'Make in India' initiatives and helped boost sales in Asia.

Offering value-added services and complete system solutions instead of standalone products is another winning formula. For example, Siemens' digital offerings like Sinamics drives, remote monitoring solutions, and digital services have seen strong demand and helped increase wallet share and customer loyalty.

Segmental Analysis of Energy-efficient Motor Market

Insights, By Efficiency Level: Super Premium-IE4 Highlight the Importance of Energy Efficiency

The super premium-IE4 segment is projected to hold 39% share in the energy-efficient motor market in 2024, in terms of efficiency level. Motors belonging to this segment offer an efficiency that is 4% higher than the best premium efficiency level motor available presently. They help reduce energy consumption and costs substantially for application areas that require continuous high-powered operations.

Stringent government regulations and policies focusing on energy efficiency and conservation are a key driver for this segment's growth. Many countries have drafted policies mandating the use of IE4 motors for new installations and also replacing old motors with new IE4 ones wherever feasible. This is compelling factories and commercial establishments to upgrade their motor systems to higher efficiency variants.

Technological advances by motor manufacturers are making IE4 units more cost-effective versus their efficiency gains. This growing affordability too spurs the super-premium-IE4 segment growth in the energy-efficient motor market.

Insights, By Application: HVAC Systems Find Extensive Usage in Residential, Commercial, and Industrial Sectors

The HVAC (heating, ventilation and air conditioning) application is projected to hold 30.6% share in the energy-efficient motor market globally. Motors used in various HVAC equipment such as chillers, fans, blowers and pumps require high precision levels and experience extensive run hours throughout the year across different sectors.

Residential HVAC systems powered by energy-efficient motors are seeing rising demand with growing construction of green buildings and smart homes worldwide. The need for all-season thermal comfort in homes along with reduced utility bills is driving homeowners to install energy-rated HVAC units in new constructions as well as replacements.

In the commercial sector spanning offices, malls, hospitals etc., the operational hours of HVAC equipment are substantially higher than domestic use. This frequent operational nature plus stringent energy compliance of commercial buildings boosts replacement of existing HVAC motors with new energy-efficient variants.

Equipment upgrades brought on by the latest HVAC technology, digitization and IoT are another factor augmenting the demand for energy-efficient motors in this application segment. Old HVAC stocks face replacements ahead of schedule to incorporate new features, often accompanied by a switch to higher-rated efficient motors as a bundled offering.

Additional Insights of Energy-efficient Motor Market

- Energy-efficient motors account for approximately 40% of the total energy consumption in industrial applications, highlighting the impact of motor efficiency on overall energy use.

- Government incentives in countries like the United States and Germany are encouraging small and medium enterprises to invest in energy-efficient technologies, boosting growth of the energy-efficient motor market.

- The integration of energy-efficient motors in HVAC systems has led to substantial energy savings in commercial buildings, reducing operational costs significantly.

- The adoption of IE4 motors in manufacturing has improved production efficiency and decreased downtime, showcasing the tangible benefits of upgrading to high-efficiency motors.

Competitive overview of Energy-efficient Motor Market

The major players operating in the energy-efficient motor market include Johnson Controls Inc., AG Regal, General Electric Company, Bosch Rexroth, Schneider Electric SE, ABB Ltd., Nidec Corporation, WEG Industries, Rockwell Automation, Inc., Crompton Greaves Consumer Electricals Ltd., and Regal Beloit Corporation.

Energy-efficient Motor Market Leaders

- Johnson Controls Inc.

- AG Regal

- General Electric Company

- Bosch Rexroth

- Schneider Electric SE

Energy-efficient Motor Market - Competitive Rivalry, 2024

Energy-efficient Motor Market

(Dominated by major players)

(Highly competitive with lots of players.)

Recent Developments in Energy-efficient Motor Market

- In April 2024, ABB India launched its IEC Low Voltage IE4 cast iron super premium efficiency motors and IE3 aluminum motors. These new products are available in various frame sizes (71-132 for the IE4 cast iron motors and 71-90 for the IE3 aluminum motors) and are aimed at improving energy efficiency across several industries, including water and wastewater management, packaging, food and beverage, metals, cement, mining, plastics, rubber, and HVAC applications.

- In March 2024, Johnson Controls and Mahindra Group launched a Net Zero Buildings Initiative aimed at decarbonizing various types of buildings in India, including commercial, urban residential, and public structures. This initiative is designed to facilitate the adoption of sustainable building technologies and promote energy-efficient solutions.

Energy-efficient Motor Market Segmentation

- By Efficiency Level

- Super Premium-IE4

- Premium-IE3

- High-IE2

- Standard-IE1

- By Application

- HVAC

- Fans

- Pumps

- Compressors

- Others

Would you like to explore the option of buying individual sections of this report?

Frequently Asked Questions :

How big is the energy-efficient motor market?

The energy-efficient motor market is estimated to be valued at USD 60.63 Bn in 2024 and is expected to reach USD 115.41 Bn by 2031.

What are the key factors hampering the growth of the energy-efficient motor market?

High initial investment costs due to premium components and limited awareness regarding the long-term benefits of energy-efficient motors are the major factors hampering the growth of the energy-efficient motor market.

What are the major factors driving the energy-efficient motor market growth?

Lower life cycle costs than traditional motors, significantly reducing operating expenses, and increasing adoption of energy-efficient motors in the industrial sector due to government regulations promoting energy efficiency are the major factors driving the energy-efficient motor market.

Which is the leading efficiency level in the energy-efficient motor market?

The leading efficiency level segment is super premium-IE4.

Which are the major players operating in the energy-efficient motor market?

Johnson Controls Inc., AG Regal, General Electric Company, Bosch Rexroth, Schneider Electric SE, ABB Ltd., Nidec Corporation, WEG Industries, Rockwell Automation, Inc., Crompton Greaves Consumer Electricals Ltd., and Regal Beloit Corporation are the major players.

What will be the CAGR of the energy-efficient motor market?

The CAGR of the energy-efficient motor market is projected to be 9.6% from 2024-2031.