Singapore Ceramic Membrane Market SIZE AND SHARE ANALYSIS - GROWTH TRENDS AND FORECASTS (2024 - 2031)

Singapore Ceramic Membrane Market is Segmented By Material (Alumina, Zirconium Oxide, Titania, Other...

Singapore Ceramic Membrane Market Size - Analysis

The Singapore Ceramic Membrane Market is estimated to be valued at USD 35.9 Mn in 2024 and is expected to reach USD 101.8 Mn by 2031, growing at a compound annual growth rate (CAGR) of 13.9% from 2024 to 2031.

Singapore's strong manufacturing industry and stringent wastewater disposal regulations have driven the demand for ceramic membranes in various industrial processing applications such as food and beverage, pharmaceuticals and chemical processing.

Market Size in USD Mn

CAGR13.9%

| Study Period | 2024 - 2031 |

| Base Year of Estimation | 2023 |

| CAGR | 13.9% |

| Market Concentration | High |

| Major Players | TAMI Industries, Pall Corporation, Veolia Water Technologies, METAWATER Co., Ltd., ItN Nanovation AG and Among Others |

please let us know !

Singapore Ceramic Membrane Market Trends

Market Driver – Technological Advancements

Technological advancements are significantly contributing to the growth of Singapore's ceramic membrane market. Ceramic membranes are increasingly being used in various industries like water and waste water treatment due to their superior durability and chemical resistance compared to polymeric membranes.

Advanced nano-filtration and ultra-filtration ceramic membranes are allowing industries to treat complex water and process streams more efficiently. For instance, ceramic nano-filtration membranes can remove difficult-to-treat matters like natural organic matter, color, hardness and micro-pollutants from water without using chemicals. This ensures higher quality of treated water within regulatory norms. Similarly, ultra-filtration ceramic membranes are enabling concentration of valuable components from industrial streams with consistent separation performance even in harsh conditions.

Furthermore, continuous research and investments into developing novel ceramic membrane materials and module configurations are expanding the application scope of these membranes. Customers can now choose from a wider portfolio of ceramic membranes tailored for their specific separation needs. For instance, titanium oxide ceramic membranes offer higher chemical stability for processing highly corrosive streams from semiconductor industry.

Market Driver – Stringent Environmental Regulations

Stringent environmental regulations implemented by the Singapore government in recent years are one of the major factors propelling the growth of ceramic membrane market in the country. Singapore has adopted some of the toughest emission norms for industrial wastewater in Asia. For example, the National Environmental Agency of Singapore has set strict discharge limits for various pollutants like COD, BOD, heavy metals etc. from 2023 onwards. Failure to meet these norms can result in heavy penalties for industries. This has increased the demand for advanced water treatment technologies that can help companies comply with regulations effectively.

Ceramic membranes have emerged as one of the preferred solutions due to their excellent pollutant removal efficiency and ability to treat complex industrial wastewater. Their nominal pore size allows them to filter out even the smallest impurities and heavy metals from wastewater. Several multinational corporations from chemical, pharmaceutical and electronics industries have already installed large scale ceramic membrane plants in their Singapore facilities to treat effluents and meet incoming discharge compliance levels.

Market Challenge – High Initial Investment

The high initial capital requirement for setting up a ceramic membrane plant is one of the major barriers constraining the growth of the ceramic membrane market in Singapore. Ceramic membranes are most suited for large-scale industrial applications due to their relatively high production costs compared to other filtration technologies. Setting up a commercial scale ceramic membrane filtration system involves a huge capital expenditure running into millions of dollars for constructing a membrane production facility, installing the filtration equipment and supporting infrastructure.

Given the capital-intensive nature, only large industrial companies have the financial capability to make such a heavy initial investment and achieve economies of scale needed to make ceramic membrane applications commercially viable. However, the number of such large industrial consumers of water filtration systems is limited in Singapore. According to the Singapore government statistics, around 95% of the businesses in Singapore are small and medium enterprises who will find it difficult to afford the high setup costs. This makes ceramic membrane technology not a preferred option for majority of the industrial and municipal customers in the country.

Market Opportunity – Diversification Into New Applications

Diversification into new applications presents a massive opportunity for growth in Singapore's ceramic membrane market. Ceramic membranes are increasingly being used beyond just water purification due to their unique capability to filter at a molecular scale. One area ripe for expansion is wastewater treatment and reuse. With a growing population putting severe pressure on Singapore's limited water resources, reusing treated wastewater has become a national priority. Ceramic membranes allow for advanced wastewater filtration that produces reusable water suitable for non-potable needs like cooling, flushing, irrigation and industrial processes. This helps offset freshwater demand. According to PUB, Singapore's National Water Agency, recycled water currently makes up 30% of Singapore's total water demand and this is targeted to increase to 55% by 2060. The expansion of ceramic membrane applications in wastewater recycling presents a multi-decade growth runway for the local industry.

Another promising avenue is in biopharmaceutical and medical manufacturing. Ceramic membranes deliver sterile-grade filtrate essential for processes like producing injections, medicines and medical devices. They are able to remove even the smallest impurities and viruses.

Segmental Analysis of Singapore Ceramic Membrane Market

Insights, By Material: Superior Hardness and Strength Properties of Alumina

Alumina contributes the highest share of 43.2% in the market Alumina ceramics membranes have emerged as the dominant material used in Singapore's water and wastewater treatment applications due to its high corrosion and heat resistance. Alumina ceramics can withstand harsh chemical environments and offer reliable performance even under extreme pH levels and temperatures fluctuating from boiling to freezing. Their non-porous and defect-free structure prevents microbial contamination of water streams. Leading utilities in Singapore have adopted alumina membranes on a large scale to filter both raw water sources and treated effluents before disposal.

The other popular material, zirconium oxide, has made inroads in niche pharmaceutical and biotech filtrations owing to its biocompatibility and non-wetting properties. Zirconium oxide membranes exhibit greater hydrophilicity than alumina, facilitating higher water fluxes. Several biologics manufacturers in Singapore have integrated zirconium oxide ceramic filters in their upstream and downstream processes to remove bacteria and viruses without compromising the delicate structures of active pharmaceutical ingredients.

Insights, By Application: Stringent Regulations on Water Quality

Water & wastewater treatment contributes the highest share of 54.2% in the market.

Water & wastewater treatment dominates the ceramic membrane market in Singapore due to stringent quality standards prescribed by the nation's Public Utilities Board (PUB). The PUB has mandated tertiary treatment of all municipal and industrial wastewaters using advanced filtration technologies to achieve near-potable quality before being discharged into the marine environment. Ceramic membranes have emerged as the technology of choice for tertiary and quaternary treatment due to their unmatched retention abilities for suspended solids and pathogens.

Many water reclamation plants in Singapore have installed large ceramic membrane bioreactor (MBR) systems to purify used waters to prescribed limits. With population growth and urbanization placing greater stress on limited water sources, membrane technologies are expected to grow further in water reuse and desalination applications to enhance Singapore's water security.

Competitive overview of Singapore Ceramic Membrane Market

The major players operating in the Singapore Ceramic Membrane Market include TAMI Industries, Pall Corporation, Veolia Water Technologies, METAWATER Co., Ltd., ItN Nanovation AG, Hyflux Ltd, Atech Innovations Gmbh, Jiangsu Jiuwu Hi-Tech Co., Gea Group, and Siva.

Singapore Ceramic Membrane Market Leaders

- TAMI Industries

- Pall Corporation

- Veolia Water Technologies

- METAWATER Co., Ltd.

- ItN Nanovation AG

Singapore Ceramic Membrane Market - Competitive Rivalry

Singapore Ceramic Membrane Market

(Dominated by major players)

(Highly competitive with lots of players.)

Recent Developments in Singapore Ceramic Membrane Market

- In December 2021, Meiden Singapore supplied ceramic membranes for world’s largest ceramic membrane bioreactor project to treat industrial used water at Singapore’s Tuas Water Reclamation Plant.

Singapore Ceramic Membrane Market Segmentation

- By Material

- Alumina

- Zirconium Oxide

- Titania

- Others

- By Application

- Water & Wastewater treatment

- Pharmaceuticals

- Food & Beverages

- Chemical Processing

- Biotechnology

- Others

- By Technology

- Ultrafiltration

- Microfiltration

- Nano filtration

- Others

Would you like to explore the option of buyingindividual sections of this report?

Vidyesh Swar is a seasoned Consultant with a diverse background in market research and business consulting. With over 6 years of experience, Vidyesh has established a strong reputation for his proficiency in market estimations, supplier landscape analysis, and market share assessments for tailored research solution. Using his deep industry knowledge and analytical skills, he provides valuable insights and strategic recommendations, enabling clients to make informed decisions and navigate complex business landscapes.

Frequently Asked Questions :

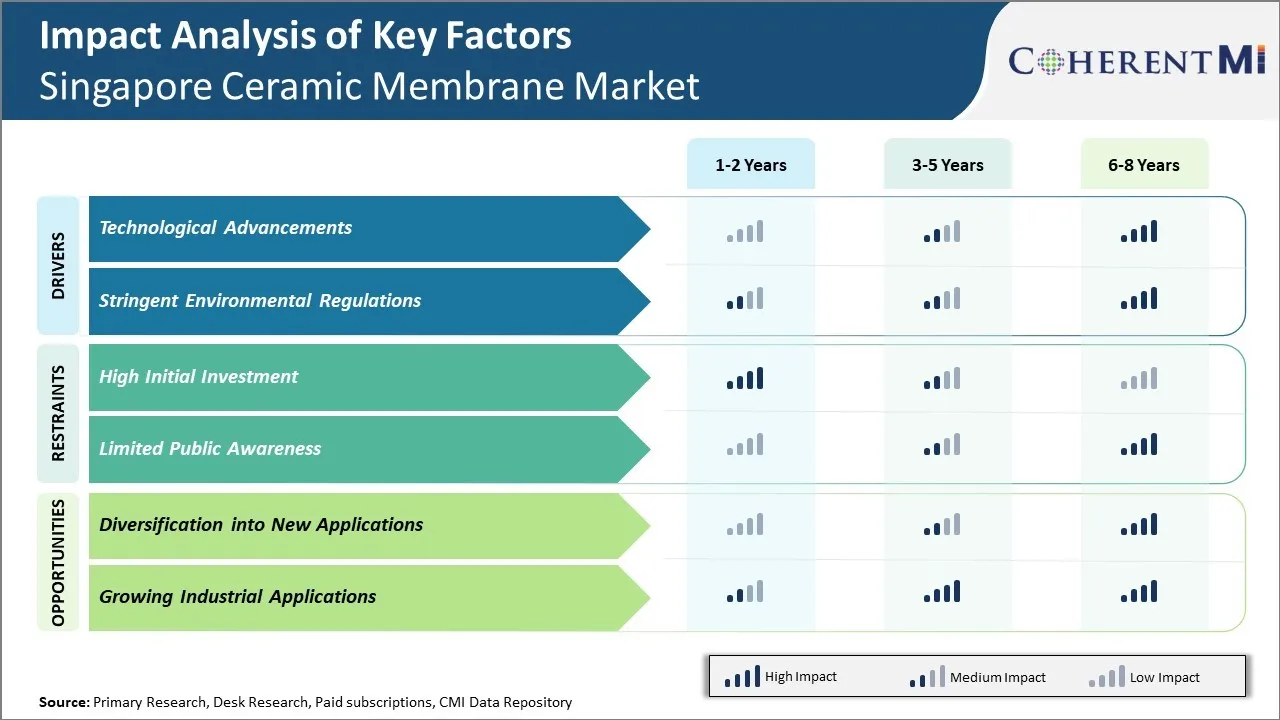

What are the key factors hampering the growth of the Singapore Ceramic Membrane Market?

The high initial investment and limited public awareness are the major factors hampering the growth of the Singapore Ceramic Membrane Market.

What are the major factors driving the Singapore Ceramic Membrane Market growth?

The technological advancements and stringent environmental regulations are the major factors driving the Singapore Ceramic Membrane Market growth.

Which is the leading Material in the Singapore Ceramic Membrane Market?

The leading Material segment is Alumina.

Which are the major players operating in the Singapore Ceramic Membrane Market?

TAMI Industries, Pall Corporation, Veolia Water Technologies, METAWATER Co., Ltd., ItN Nanovation AG, Hyflux Ltd, Atech Innovations Gmbh, Jiangsu Jiuwu Hi-Tech Co., Gea Group, and Siva are the major players.

What will be the CAGR of the Singapore Ceramic Membrane Market?

The CAGR of the Singapore Ceramic Membrane Market is projected to be 13.9% from 2024-2031.