Mercado de iluminação à prova de explosões ANÁLISE DE TAMANHO E PARTICIPAÇÃO - TENDÊNCIAS DE CRESCIMENTO E PREVISÕES (2024 - 2031)

Mercado de iluminação à prova de explosões é segmentado por tipo (Iluminação Geral, Dilúvios, Luzes Compactas, Outros), por tipo de luz (Luzes LED, Lu....

Mercado de iluminação à prova de explosões Tamanho

Tamanho do mercado em USD Bn

CAGR9.9%

| Período de estudo | 2024 - 2031 |

| Ano base da estimativa | 2023 |

| CAGR | 9.9% |

| Concentração de Mercado | Medium |

| Principais jogadores | Emerson Electric Co., Elétrica Geral, Eaton Corporation Inc., Hubbell Inc., Iluminação Wipro e entre outros |

por favor, avise-nos!

Mercado de iluminação à prova de explosões Análise

Estima-se que o Global Explosion Proof Lighting Market seja avaliado em USD 369.1 Bn em 2024 e é esperado alcançar USD 788.1 Bn por 2031, crescimento em uma taxa de crescimento anual composto (CAGR) de 9,9% de 2024 a 2031.

O Mercado de Iluminação à Prova de Explosão tem testemunhado um crescimento significativo nos últimos anos devido ao aumento da demanda de petróleo e gás, mineração e outras indústrias perigosas. Houve um investimento substancial no desenvolvimento e expansão de instalações industriais que exigem soluções de iluminação à prova de explosão para garantir a segurança operacional. Além disso, regulamentos rigorosos sobre o uso de luzes em zonas perigosas em todo o mundo continuará a conduzir a necessidade de luminárias à prova de explosão certificadas. Os avanços na tecnologia LED que permitem tochas e lâmpadas à prova de explosão com maior eficácia ao custo otimizado também estão aumentando o mercado. No entanto, a disponibilidade de técnicas de substituição para iluminação e altos custos iniciais envolvidos pode restringir o mercado em certa medida durante o período de previsão.

Mercado de iluminação à prova de explosões Tendências

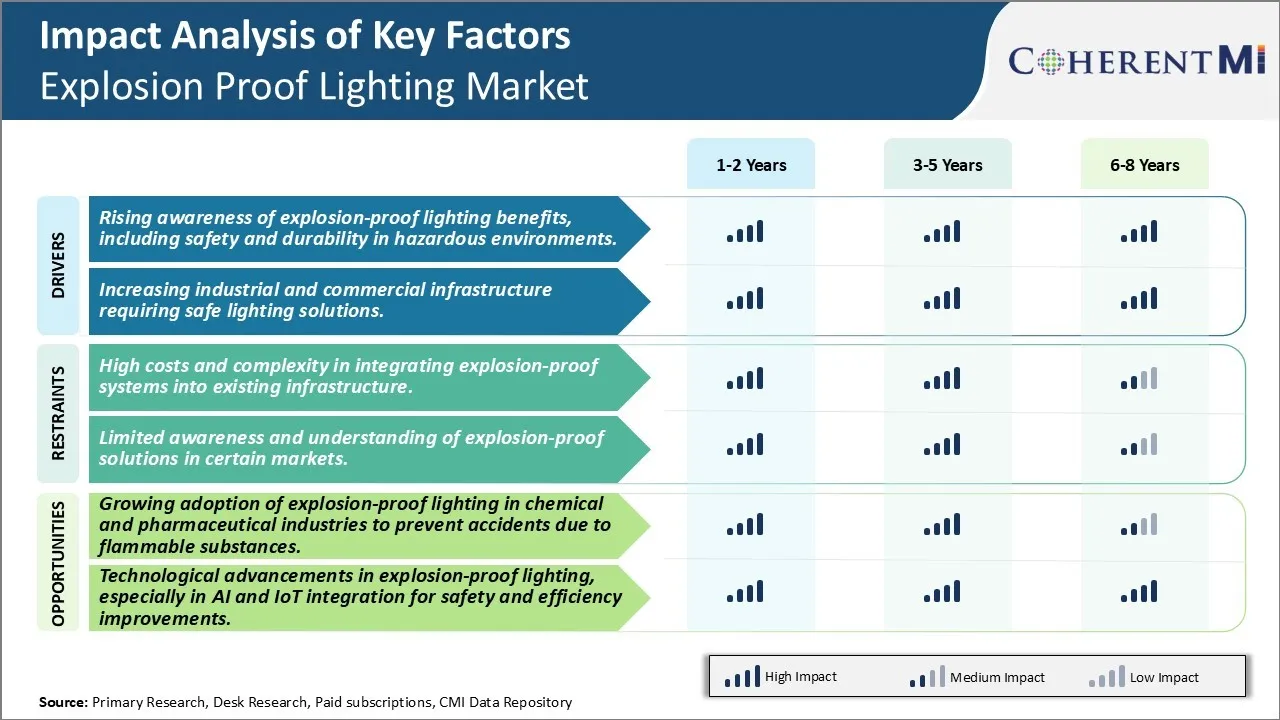

Driver de mercado - Aumentar a consciência dos benefícios de iluminação à prova de explosão, incluindo segurança e durabilidade em ambientes perigosos

O uso de soluções de iluminação à prova de explosão tornou-se cada vez mais importante em ambientes industriais perigosos, onde o risco de explosões devido a gases inflamáveis, vapores e partículas de poeira é sempre presente. Tradicionalmente, os operadores em tais espaços confiavam em lâmpadas incandescentes que carregavam riscos significativos de inflamar substâncias combustíveis. No entanto, com crescente conscientização sobre a necessidade crucial de segurança em zonas de alto risco, muitos gerentes de instalações e contratados estão agora reconhecendo os principais benefícios oferecidos pelos sistemas de iluminação LED à prova de explosão certificados.

Estes equipamentos modernos à prova de explosões são projetados e testados para rigorosas certificações internacionais para garantir que não podem causar faíscas ou altas temperaturas de superfície mesmo em caso de falhas ou maus funcionamentos. Lâmpadas LED possuem uma vida operacional mais longa em comparação com lâmpadas incandescentes tradicionais, reduzindo assim os custos de manutenção e substituição ao longo do tempo. Além disso, as luzes LED à prova de explosão consomem até 90% menos energia ao fornecer saída de lúmen semelhante ou superior. Isso os torna uma escolha muito mais eficiente de energia para aplicações industriais, oferecendo economia significativa na escalada de contas de eletricidade.

Importante, luzes à prova de explosões LED também emitem muito menos calor em comparação com outros tipos de iluminação. Isso reduz o risco de gases potencialmente explosivos serem ignidos por um dispositivo de luz de sobrecarga. Projetos avançados com dissipadores de calor e ventiladores ajudam a dissipar o calor rapidamente para manter as temperaturas de operação seguras em todas as condições. Os invólucros resistentes à quebra, policarbonato de luzes LED também os tornam alternativas mais seguras para lâmpadas de vidro comumente vistas em zonas industriais perigosas. No geral, o custo total de propriedade sobre a vida útil é muito menor para luzes LED à prova de explosão vis-a-vis tecnologias de iluminação mais antigas, uma vez que os custos de manutenção são fatorados.

Com maior conscientização sobre tais benefícios tangíveis, muitas indústrias como a produção de petróleo e gás, plantas químicas e petroquímicas, instalações de mineração, manuseio de grãos e locais de armazenamento, entre outras, têm sido proativamente atualizando para luzes LED à prova de explosão certificadas. Os órgãos reguladores também desempenham um papel ao apertar as normas de segurança e inspecionar a conformidade. Isso está impulsionando aumentos de gastos em soluções de iluminação à prova de explosão de alta qualidade para mitigar riscos em ambientes de trabalho perigosos e otimizar a eficiência operacional através de economia de energia e redução do tempo de inatividade.

Driver de mercado - Aumentando a infraestrutura industrial e comercial exigindo soluções de iluminação segura

A rápida urbanização e o crescimento industrial em grandes economias globais têm vindo a impulsionar investimentos maciços em novas fábricas de fabricação, instalações de processamento, armazéns, infraestrutura de transporte e logística ao longo da última década. Os projetos de Greenfield em indústrias como produtos químicos e petroquímicos, energia e energia, metais e mineração, produtos farmacêuticos, petróleo e gás e outros frequentemente exigem a instalação de soluções de iluminação à prova de explosões desde a fase de planejamento e projeto até operações à prova de futuro.

Enquanto isso, o envelhecimento da infraestrutura industrial também está passando por grandes renovações e expansões para aumentar as capacidades de produção e adotar automação avançada e robótica. Isto apresenta uma grande oportunidade para a substituição da iluminação existente com luminárias LED à prova de explosão certificadas em zonas perigosas. As normas regulatórias em evolução em torno da segurança do local de trabalho em muitas nações também determinam auditorias e atualizações periódicas para garantir que todos os equipamentos elétricos em áreas perigosas estejam em conformidade com as mais recentes certificações credenciadas internacionalmente. O não cumprimento leva o risco de desligamentos de produção e pesadas penalidades financeiras.

Além disso, o mercado de iluminação à prova de explosão está vendo maior aumento além das aplicações tradicionais da indústria pesada também. Os setores de crescimento, como armazenagem e logística, fabricação de bens combustíveis, instalações de processamento de grãos e depósitos de armazenamento de combustível reconhecem cada vez mais a importância da iluminação segura certificada para suas áreas operacionais muitas vezes espaçosas. Isso é esperado para abrir fluxos de receita mais recentes para fabricantes de luminárias à prova de explosão nos próximos anos.

Ao abordar as necessidades de iluminação de modernizar rapidamente a infraestrutura industrial, bem como uma base de adoção de produtos de ampliação, a indústria de iluminação à prova de explosão é bem posicionado para impulso sustentado.

Desafio de Mercado - Altos Custos e Complexidade na integração de Sistemas de Prova de Explosão em Infraestrutura Existente

Um dos principais desafios enfrentados pelo mercado de iluminação à prova de explosão é os altos custos e complexidade envolvidos na integração de sistemas de iluminação à prova de explosão em infraestrutura existente. A renovação das instalações industriais existentes, refinarias e instalações químicas com iluminação à prova de explosão requer investimentos substanciais de capital, uma vez que toda a fiação existente e dispositivos elétricos precisam ser substituídos ou atualizados. Isso leva a um tempo de inatividade prolongado para instalações durante a transição que pode afetar a produtividade e incorrer em perdas. Além disso, os sistemas de prova de explosão têm rigorosos padrões de conformidade e requisitos de certificação que precisam ser seguidos durante a instalação, o que aumenta os custos. As complexidades em garantir a classificação da área zonal como por normas da indústria e corretamente instalar luzes que atendam a esses padrões de classificação em vastos espaços industriais também contribuem para maiores despesas de instalação e manutenção em sistemas de iluminação convencionais. Os gerentes de facilidade podem hesitar em realizar tais upgrades, a menos que crítico como retorno sobre os investimentos possam demorar mais tempo devido a alta superação de capital inicial.

Oportunidade de mercado: Adoção crescente da iluminação à prova de explosões em indústrias químicas e farmacêuticas para prevenir acidentes devido a substâncias inflamáveis

Uma das principais oportunidades para o mercado de iluminação à prova de explosão é a adoção crescente desses sistemas de iluminação nas indústrias química e farmacêutica. Locais de trabalho que lidam com substâncias voláteis ou inflamáveis estão em alto risco de incêndios e explosões se a iluminação convencional é usada devido à presença de fontes de ignição. Assim, há uma demanda aumentada para luminárias intrinsecamente seguras que podem prevenir faíscas ou geração de calor anormal em áreas onde fumes ou poeiras combustíveis podem estar presentes. A necessidade de garantir que o pessoal e a segurança das instalações obrigaram os gestores de segurança nestas indústrias a substituir proativamente as luzes existentes por sistemas à prova de explosão. Além disso, acidentes resultantes de atmosferas combustíveis podem causar tempo de inatividade da produção, responsabilidades legais e reputação de marca de danos. Assim, as empresas estão cada vez mais fazendo investimentos de capital em iluminação de prova de explosão certificada como uma medida preventiva para evitar tais riscos e manter a continuidade das operações. Este foco crescente na segurança do processo e do pessoal continuará impulsionando a adoção desses sistemas de iluminação especializados durante o período de previsão.

Principais estratégias vencedoras adotadas pelos principais participantes de Mercado de iluminação à prova de explosões

Inovação do produto e avanços tecnológicos

- Investir em R&D para desenvolver soluções inovadoras de iluminação que proporcionam maior durabilidade, melhor eficiência energética e melhor iluminação em ambientes perigosos.

- Integração da tecnologia LED para oferecer opções de iluminação energeticamente eficientes e duradouras adequadas para ambientes explosivos e perigosos.

Foco em conformidade e certificação

- Aderindo a regulamentos de segurança rigorosos e obtendo certificações (como ATEX, IECEx, UL e CSA) para atender aos padrões internacionais para produtos à prova de explosão.

- Atualizações regulares e redesigns de produtos para cumprir com os mais recentes regulamentos de segurança e requisitos de mercado.

Expansão em mercados de alta crescimento

- Visando indústrias de alto crescimento, como petróleo e gás, mineração, produtos químicos e produtos farmacêuticos, onde a iluminação à prova de explosão é essencial.

- Expandindo as redes de vendas e distribuição em mercados emergentes, particularmente em regiões como Ásia-Pacífico, Oriente Médio e América Latina, onde a industrialização está acelerando.

Parcerias Estratégicas e Colaborações

- Em parceria com instalações industriais, OEMs e canais de distribuição para aumentar o alcance do mercado e garantir a disponibilidade do produto em mercados-chave.

- Colaborando com especialistas da indústria e empresas de consultoria para desenvolver soluções de iluminação à prova de explosão personalizadas adaptadas às necessidades específicas do cliente.

Fase sobre eficiência energética e sustentabilidade

- Desenvolver sistemas de iluminação energeticamente eficientes que ajudam a reduzir o consumo de energia e os custos operacionais em indústrias intensivas em energia.

- Foque em materiais e projetos ecológicos que se alinham com iniciativas de energia verde e objetivos de sustentabilidade ambiental.

Análise Segmental de Mercado de iluminação à prova de explosões

Insights, por tipo, qualidade e confiabilidade Drives Segmento de iluminação geral

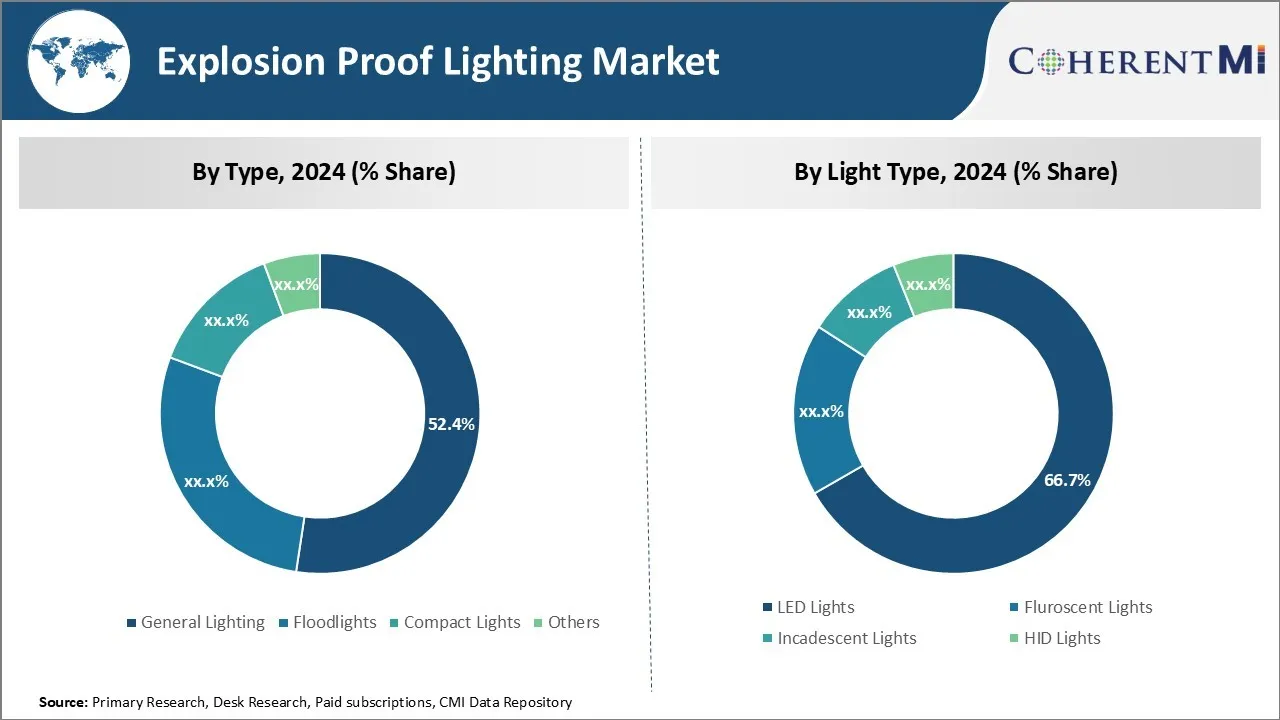

Por tipo, a iluminação geral é projetada para contribuir 52,4% em 2024 devido à sua capacidade de fornecer iluminação consistente e de alta qualidade para uma variedade de ambientes industriais perigosos. Os dispositivos elétricos de iluminação geral são projetados com certificações à prova de explosão para suportar gases combustíveis, poeira e fibras sem causar faíscas ou calor que poderiam inflamar substâncias inflamáveis. Eles oferecem luz branca de espectro completo que melhora a visibilidade e segurança em comparação com luzes de risco de baixa intensidade. Além disso, os dispositivos elétricos de iluminação geral duram até 50.000 horas antes de exigir substituições de lâmpada, reduzindo os custos de manutenção. Seu brilho cria uma área de trabalho segura e confortável sem sombras ou manchas escuras que obscurecem tarefas de trabalho ou perigos. A confiabilidade da iluminação geral ajuda a minimizar as interrupções nos fluxos de trabalho de produção e garante a segurança do trabalhador mesmo nas zonas mais perigosas.

Insights, por tipo de luz, inovação constante impulsiona a adoção do LED

Por tipo de luz, as luzes LED representaram 66,7% em 2024 com uma maior penetração de mercado devido às suas vantagens de desempenho sobre as tecnologias de iluminação tradicionais. Os LEDs fornecem luz branca nítida com renderização de alta cor para a acuidade visual enquanto consomem energia mínima. Seu tamanho compacto permite a instalação flexível sem comprometer carcaças à prova de explosão. Ao contrário das lâmpadas de descarga de gás, os LEDs não contêm materiais perigosos como o vapor de mercúrio e não quebram se danificado. Mais importante, a tecnologia LED continua a avançar a cada ano com maior luminosidade, maior vida útil e menores custos - ultrapassando fontes de luz concorrentes. À medida que a eficiência do LED melhora, as economias operacionais superam os custos iniciais mais elevados. Os fabricantes continuarão desenvolvendo controles de LED inteligentes e materiais de próxima geração para maximizar a economia de energia dentro de configurações industriais perigosas. A inovação constante cimenta luzes LED como a tecnologia de iluminação à prova de explosão preferida.

Informação adicional de Mercado de iluminação à prova de explosões

O Mercado de Iluminação à Prova de Explosão está pronto para o crescimento, pois as indústrias adotam cada vez mais a iluminação à prova de explosões para evitar acidentes em ambientes de alto risco, como refinarias de petróleo e plantas químicas. Luzes à prova de explosão, particularmente variantes LED, oferecem segurança, durabilidade e eficiência energética, tornando-os uma escolha preferida em locais perigosos. Os avanços tecnológicos, como a integração da IA para monitoramento em tempo real e manutenção preditiva, aumentam ainda mais a proposta de valor dos sistemas de iluminação à prova de explosão. Esta tendência é impulsionada por mandatos regulatórios para o cumprimento da segurança e uma crescente consciência da segurança no local de trabalho. À medida que a industrialização se expande, particularmente na Ásia-Pacífico e América do Norte, espera-se que a demanda por soluções de iluminação à prova de explosão cresça, com LEDs que levam devido à sua eficiência e menores custos operacionais. O mercado está bem posicionado para o crescimento contínuo, apoiado por inovações contínuas em tecnologia de iluminação.

Visão geral competitiva de Mercado de iluminação à prova de explosões

Os principais jogadores que operam no Mercado de Iluminação da Prova de Explosão incluem Emerson Electric Co., General Electric, Eaton Corporation Inc., Hubbell Inc., Wipro Lighting, Glamox As, Cortem S.P.A., Larson Electronics LLC, Atomsvet LLC, LDPI Inc. e NORKA Lighting.

Mercado de iluminação à prova de explosões Líderes

- Emerson Electric Co.

- Elétrica Geral

- Eaton Corporation Inc.

- Hubbell Inc.

- Iluminação Wipro

Mercado de iluminação à prova de explosões - Rivalidade Competitiva

Mercado de iluminação à prova de explosões

(Dominado por grandes players)

(Altamente competitivo com muitos jogadores.)

Desenvolvimentos recentes em Mercado de iluminação à prova de explosões

- Em maio de 2024, a FANUC America lançou o robô colaborativo de pintura CRX-10iA/L, o primeiro robô de pintura colaborativa à prova de explosão projetado para uso global.

- Em janeiro de 2023, a ARCHON Industries Inc. introduziu a iluminação à prova de explosões EX20-100, projetada para iluminação contínua em locais perigosos como embarcações de processo e tanques.

- Em janeiro de 2023, a Wipro Lighting lançou a BlazelineTM, uma gama de iluminação à prova de chamas que fornece soluções robustas e confiáveis para ambientes perigosos.

- Em outubro de 2022, o THT-EX revelou a primeira luz LED à prova de calor e à prova de explosão aprovada pelo mundo, projetada para suportar altas temperaturas e condições empoeiradas.

Mercado de iluminação à prova de explosões Segmentação

- Por tipo

- Iluminação geral

- Luzes de inundação

- Luzes compactas

- Outros

- Por tipo de luz

- LED LED LED Luzes

- Luzes fluorescentes

- Luzes Incadescentes

- Luzes HID

- Por End-use

- Óleo e Gás

- Produtos químicos

- Farmacêutica

- Mineração

- Energia e Energia

- Outros

Gostaria de explorar a opção de comprasecções individuais deste relatório?

Perguntas Frequentes :

Quão grande é o mercado de iluminação à prova de explosões?

Estima-se que o Global Explosion Proof Lighting Market seja avaliado em USD 369.1 Bn em 2024 e deverá chegar a USD 788.1 Até 2031.

Qual será o CAGR do Mercado de Iluminação à Prova de Explosão?

O CAGR do Mercado de Iluminação à Prova de Explosão é projetado para ser de 9,9% de 2024 a 2031.

Quais são os principais fatores que impulsionam o crescimento do mercado de iluminação à prova de explosões?

A crescente conscientização sobre os benefícios de iluminação à prova de explosão, incluindo segurança e durabilidade em ambientes perigosos e aumentando a infraestrutura industrial e comercial exigindo soluções de iluminação seguras. são os principais fatores que impulsionam o mercado de iluminação à prova de explosões.

Quais são os principais fatores que dificultam o crescimento do Mercado de Iluminação Prova de Explosão?

Os altos custos e complexidade na integração de sistemas à prova de explosão em infraestrutura existente e consciência limitada e compreensão de soluções à prova de explosão em certos mercados são os principais fatores que dificultam o crescimento do Mercado de Iluminação à Prova de Explosão.

Qual é o tipo líder no mercado de iluminação à prova de explosões? x

A Iluminação Geral é o segmento Tipo líder.

Quais são os principais jogadores que operam no Mercado de Iluminação de Prova de Explosão?

Emerson Electric Co., General Electric, Eaton Corporation Inc., Hubbell Inc., Wipro Lighting, Glamox As, Cortem S.P.A., Larson Electronics LLC, Atomsvet LLC, LDPI Inc., NORKA Iluminação são os principais jogadores.