Sandblasting Machines Market SIZE AND SHARE ANALYSIS - GROWTH TRENDS AND FORECASTS (2024 - 2031)

Sandblasting Machines Market is segmented By Product (Stationary Sandblaster, Portable Sandblaster), By Operation (Semi-automatic, Manual, Automatic),....

Sandblasting Machines Market Size

Market Size in USD Mn

CAGR5.4%

| Study Period | 2024 - 2031 |

| Base Year of Estimation | 2023 |

| CAGR | 5.4% |

| Market Concentration | High |

| Major Players | Clemco Industries Corporation, Graco Inc., Airblast B.V., Sinto Group, Guyson Corporation and Among Others. |

please let us know !

Sandblasting Machines Market Analysis

The Global Sandblasting Machines Market is estimated to be valued at USD 500.8 Mn in 2024 and is expected to reach USD 765.4 Mn by 2031, growing at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2031. The growing demand from automotive and manufacturing industries is driving the need for surface treatment techniques like sandblasting. The sandblasting machines market is expected to witness positive growth over the forecast period. Increasing applications of sandblasting across various end-use industries such as automotive, construction, metalworking and others are expected to support the demand of these machines. Additionally, growing infrastructure development activities in potentially developing countries is aimed at contributing to the market expansion.

Sandblasting Machines Market Trends

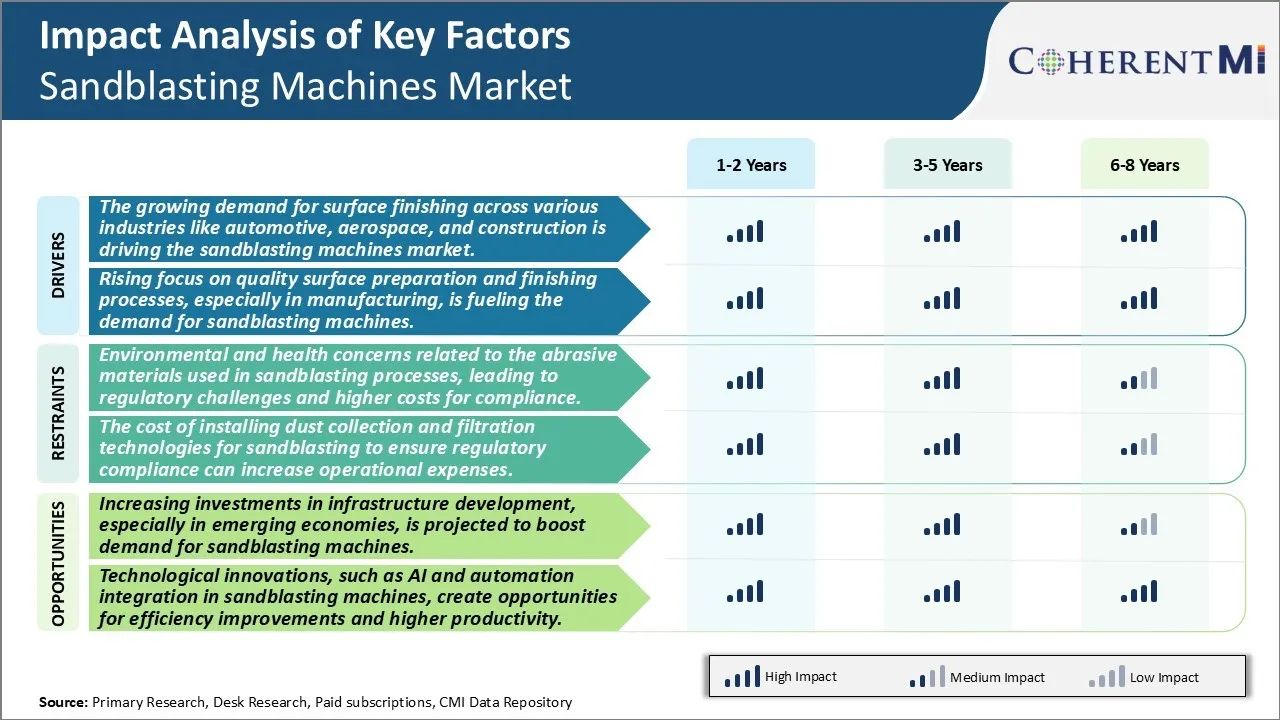

Market Driver - The Growing Demand for Surface Finishing Across Various Industries Like Automotive, Aerospace, and Construction is Driving the Sandblasting Machines Market

The demand for surface finishing processes across major industries has been steadily rising over the past few years. This growing emphasis on aesthetics and durability of finished products has translated into increased uptake of sandblasting machines. Surface finishing plays an important role in determining the functionality and life of components used in automobiles, aircraft, construction material and other engineered products. Whether for decorative, protective or preparatory purposes, achieving the desired surface attributes through techniques like sandblasting has become imperative.

The automotive industry in particular has raised the bar as far as exterior and interior looks are concerned. Car owners now expect flawless paint finishes, scratch-resistant coated trim pieces and finely sanded logos/texturing. Similarly, modern aircraft designs involve complex contours that mandate specialized preparation of metallic alloys through abrasive blasting before further coating. On the construction front, sandblasting lends durability and aesthetic appeal to building materials such as concrete, bricks, floor tiles etc. It creates microscopic surface roughness essential for ensuring adhesion of subsequent protective layers. All these end-use sectors have substantially higher quality standards today than in the past, placing greater technical requirements on preprocessing methods.

A direct consequence of the augmented quality demands across industries has been a surge in customization of sandblasting equipment. Machines now accommodate variable nozzle sizes, media types, pressures and automated controls to achieve consistent results on small batches of intricate parts. Portable, compact variants have also gained favor for on-site surface treatment of large structures. The growing preference for renting sandblasting units instead of capital expenditure additionally points towards an expanding addressed market. While basic blast cabinets suffice for low volume jobs, sophisticated robotic sandblasters are increasingly used in automated manufacturing lines to boost productivity.

Market Driver - Focus on Optimizing Surface Preparation Processes Encourages the Deployment

With current competitive pressures on manufacturers to lower costs and accelerate throughput, there is heightened focus on streamlining production workflows. An often-overlooked yet important step influencing overall efficiency is effective surface preparation prior to painting, coating, or other value-adding processes. Advanced surface preparation techniques ensure proper substrate readiness and adhesion of subsequent finishing layers as per quality norms and engineering specifications. Among available methods, sandblasting stands out for its versatility and reliability in achieving the targeted surface profile on a wide range of materials.

However, conventional manual sandblasting is labor-intensive with inherent inconsistencies. Seeking optimization, manufacturers now emphasize deploying technologically proficient surface treatment resources. Automated and robotic sandblasting systems in particular address issues of reproducibility and ergonomics. Such sophisticated machines allow for digital programming of variables to precisely control media flow, angle of impact and sweeping motion. They are useful in mass-producing identical components by ensuring uniform blasting across batches. The ability to be integrated seamlessly into automated production lines further increases their appeal. Additionally, dust extraction functionalities minimizes cleanup and improves plant occupational safety.

With the Industrial Internet of Things accelerating, there is a concurrent push towards smart connected equipment featuring remote monitoring capabilities. The benefits of condition-based predictive maintenance and data-based process enhancements are compelling manufacturers to upgrade existing sandblasting tools as well. They can leverage technologies such as sensors, software and AI to optimize surface preparation cycles and resources spent on them. All these evolving needs, from initial batch preparation to predictive upkeep, signify sandblasting machinery will remain central to forward-thinking manufacturers focused on reaping Industry 4.0 dividends.

Market Challenge - Environmental and Health Concerns Related to the Abrasive Materials Used in Sandblasting Processes, Leading to Regulatory Challenges and Higher Costs For Compliance

One of the major challenges faced by the sandblasting machines market is the environmental and health concerns related to the abrasive materials used in sandblasting processes. Sandblasting involves the use of abrasive materials like silica sand, aluminium oxide, garnet and glass beads which pose serious health hazards. Prolonged exposure to these materials can cause respiratory illnesses like silicosis. There are also environmental concerns regarding the waste generated during sandblasting containing toxic materials. Strict regulations have been imposed in many countries regarding the use, handling and disposal of these abrasive materials. Companies operating in the sandblasting machines market have to comply with various norms for dust extraction and filtration. This leads to higher compliance costs for vendors. Overall, the regulatory challenges arising from environmental and health risks associated with abrasive materials used in sandblasting pose a major hurdle for the growth of sandblasting machines market.

Market Opportunity- Increasing Infrastructure Investments Fuels the Industry Growth

One significant opportunity for the sandblasting machines market is the rising infrastructure investments, particularly in developing nations. Sandblasting finds wide application in cleaning and preparing surfaces for painting, coating and other applications in construction industry. The ongoing infrastructure boom in Asia Pacific and Middle East countries is driving large number of projects in sectors like transportation, energy and buildings. This is expected to generate substantial demand for surface preparation activities including sandblasting. The growing construction activities are projected to boost the sales of sandblasting machines in the coming years. Market players could leverage the infrastructure-led economic growth in emerging markets to increase their revenues.

Key winning strategies adopted by key players of Sandblasting Machines Market

Product innovation: Major players such as AB SHOT TECNICS, S.L., Blasting and Coating Equipment, Bartell Glosbal, CLEMCO INDUSTRIES, and Empire Abrasive Equipment have focused on continuous product innovation to provide advanced sandblasting machines tailored to specific end-use requirements. For example, in 2021, AB SHOT launched the AB-Jet 6400 electric portable blasting machine that offers superior mobility, easy operation, and automated controls. Its lightweight yet robust design makes it highly suitable for on-site industrial blasting applications.

Development of eco-friendly systems: With growing environmental regulations, players shifted their focus towards developing eco-friendly sandblasting systems around 2015-2020. CLEMCO introduced the Eco-Blaster recirculation blasting system that captures and recycles spent abrasive, minimizing waste generation. Such sustainable systems helped companies strengthen their compliance profile and gain an edge in Europe and North America.

Geographic Expansion: Major global players like BARTSCH-ING and Sintokogio expanded their operations to emerging countries like India and Brazil between 2010 to 2018 via partnerships and acquisitions. This helped gain access to fast-growing regional markets before local rivals and established early-mover advantage. For example, BARTSCH-ING's 2012 acquisition of Indian manufacturer Winoa propelled its Asia Pacific revenues by 30% yearly, making it the market leader.

Development of Integrated Solutions: Post-2020, companies integrated auxiliary systems like dust collectors, robots, and software with sandblasting units to provide complete automated solutions. Sintokogio's robotic blasting cells launched in 2020 boosted productivity by 40% for automotive customers.

Segmental Analysis of Sandblasting Machines Market

Insights, By Product, Reliability and Control Drive Growth in Stationary Sandblasters

By Product, Stationary Sandblaster is expected to contribute 66.4% market share in 2024 owing to their ability to deliver consistent, high-quality results over extended periods of time. Their fixed installation allows for robust build and more powerful maintenance-free motors compared to portable options. This reliability is key in commercial applications like heavy fabrication where downtime is costly. Stationary units also offer superior control through features like variable speed belts, pressure regulators, and custom nozzle configurations. Operators can precisely target specific surfaces or intricate areas without struggling with hoses or exhaust as with portable sanders. This level of customization and control improves efficiency for any blasting task. Larger work chambers on stationary machines further boost productivity by allowing bulk batch processing.

Insights, By Operation, Operational Simplicity Favors Semi-automatic Sandblasters

By Operation, Semi-automatic sandblasters are expected to contribute 53.8% market share in 2024 for their ideal balance of simplicity and functionality. Not requiring constant attention like fully manual blasters, semi-auto units reduce operator fatigue over long jobs. Their automated feeding and containment systems also cut costs versus manual collection and replenishing of abrasives. However, semi-auto sanders still afford users control over start/stop and flow adjustments for different applications or sensitive surfaces. This ensures optimal results without wasting material. The “set it and forget it” aspect further boosts throughput in production environments compared to fully automatic options lacking adjustability.

Insights, By Blasting Type, Water Scarcity Drives Demand for Dry Sandblasting Techniques

By Blasting Type, Dry Sandblasting contributes the highest share as water availability declines in many regions. Dry techniques use compressed air to propel non-wetted abrasives like silica sand or corn cob grit against surfaces. As water shortages grow more acute—through drought, overuse or cost—dry blasting proves increasingly essential. It avoids dependence on this precious resource, as well as messy sludge runoff and treatment from wet methods. Dry sanders are also well-suited to applications like paint stripping and surface preparation where moisture would cause damage or rust. Tightening environmental regulations on wastewater meanwhile push more industries to adopt “waterless” abrasive technologies. All together, these benefits of conserving water through dry sandblasting techniques will continue spurring market expansion.

Additional Insights of Sandblasting Machines Market

The global sandblasting machines market is projected to grow steadily, driven by increasing demand for surface preparation and finishing processes in industries such as automotive, aerospace, and construction. The Asia Pacific region leads the market due to rapid industrialization, while North America is expected to experience the fastest growth due to infrastructural projects and demand from the aerospace sector. However, environmental and health concerns related to dust and airborne particles from sandblasting processes are a significant restraint, leading to increased regulatory compliance costs. Advances in technology, particularly AI and automation, are expected to boost efficiency and productivity, making sandblasting machines more adaptable to diverse industries. Additionally, infrastructure investments, particularly in emerging economies, will continue to fuel market growth. The market for portable sandblasting machines is also expected to grow, driven by demand from construction and shipbuilding industries, while the stationary sandblasters remain dominant in industrial applications.

Competitive overview of Sandblasting Machines Market

The major players operating in the Sandblasting Machines Market include Clemco Industries Corporation, Graco Inc., Airblast B.V., Sinto Group, Guyson Corporation, Burwell Technologies, Empire Abrasive Equipment, Graco Inc., Kramer Industries Inc., Laempe Mössner Sinto GmbH and Midwest Finishing Systems, Inc.

Sandblasting Machines Market Leaders

- Clemco Industries Corporation

- Graco Inc.

- Airblast B.V.

- Sinto Group

- Guyson Corporation

Sandblasting Machines Market - Competitive Rivalry, 2024

Sandblasting Machines Market

(Dominated by major players)

(Highly competitive with lots of players.)

Recent Developments in Sandblasting Machines Market

- In August 2024, Clemco Industries launched its new line of EcoQuip 2 vapor abrasive blasting machines, designed to address environmental regulations and improve performance in industrial applications.

- In July 2024, Graco Inc. entered a strategic partnership with BlastOne International, focusing on surface preparation and protective coating solutions. The partnership aims to drive innovation in sandblasting equipment for industrial applications.

Sandblasting Machines Market Segmentation

- By Product

- Stationary Sandblaster

- Portable Sandblaster

- By Operation

- Semi-automatic

- Manual

- Automatic

- By Blasting Type

- Wet Sandblasting

- Dry Sandblasting

- By Industry

- Marine

- Construction

- Automotive

- Metal Fabrication& Manufacturing

- Others

Would you like to explore the option of buying individual sections of this report?

Frequently Asked Questions :

How Big is the Sandblasting Machines Market?

The Global Sandblasting Machines Market is estimated to be valued at USD 500.8 Mn in 2024 and is expected to reach USD 765.4 Mn by 2031.

What will be the CAGR of the Sandblasting Machines Market?

The CAGR of the Sandblasting Machines Market is projected to be 5.4% from 2024 to 2031.

What are the major factors driving the Sandblasting Machines Market growth?

The growing demand for surface finishing across various industries like automotive, aerospace, and construction is driving the sandblasting machines market. Thes rising focus on quality surface preparation and finishing processes, especially in manufacturing, is fueling the demand for sandblasting machines are the major factors driving the Sandblasting Machines Market.

What are the key factors hampering the growth of the Sandblasting Machines Market?

The environmental and health concerns related to the abrasive materials used in sandblasting processes, leading to regulatory challenges and higher costs for compliance. The cost of installing dust collection and filtration technologies for sandblasting to ensure regulatory compliance can increase operational expenses are the major factors hampering the growth of the Sandblasting Machines Market.

Which is the leading Product in the Sandblasting Machines Market?

Stationary Sandblaster is the leading Product segment.

Which are the major players operating in the Sandblasting Machines Market?

Clemco Industries Corporation, Graco Inc., Airblast B.V., Sinto Group, Guyson Corporation, Burwell Technologies, Empire Abrasive Equipment, Graco Inc., Kramer Industries Inc., Laempe Mössner Sinto GmbH, Midwest Finishing Systems, Inc. are the major players.