Sandblasting Machines Market Trends

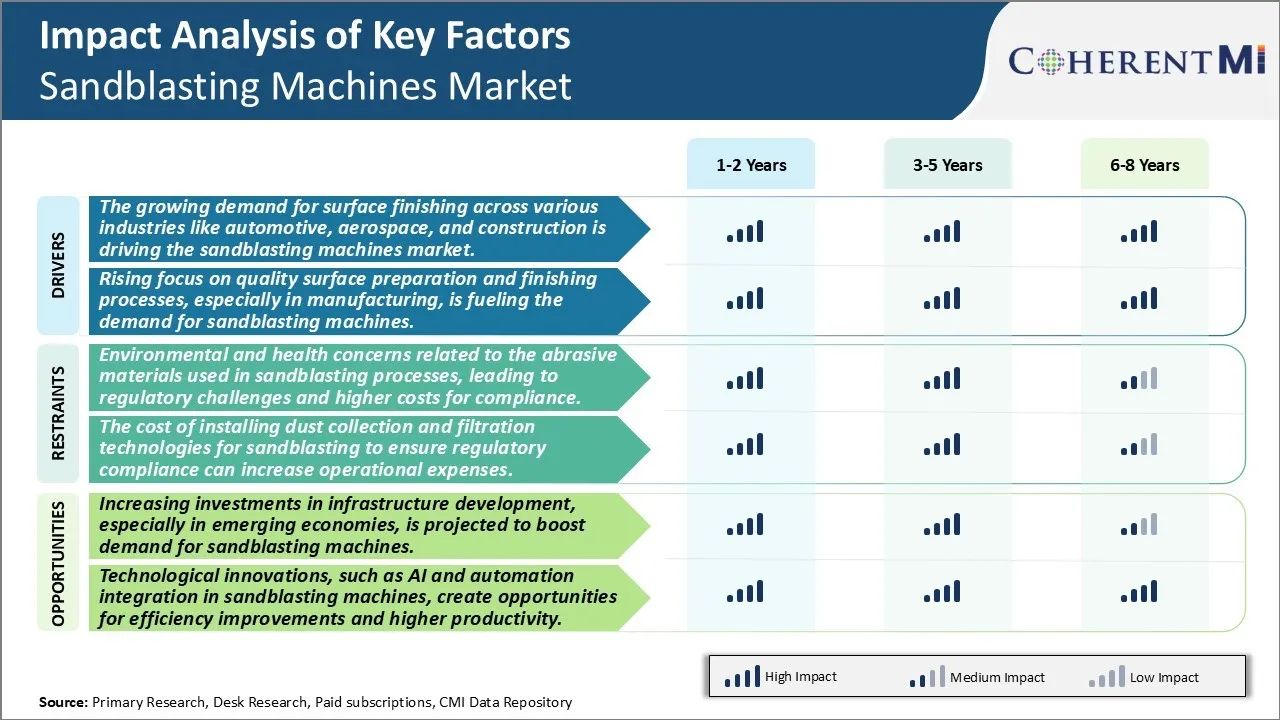

Market Driver - The Growing Demand for Surface Finishing Across Various Industries Like Automotive, Aerospace, and Construction is Driving the Sandblasting Machines Market

The demand for surface finishing processes across major industries has been steadily rising over the past few years. This growing emphasis on aesthetics and durability of finished products has translated into increased uptake of sandblasting machines. Surface finishing plays an important role in determining the functionality and life of components used in automobiles, aircraft, construction material and other engineered products. Whether for decorative, protective or preparatory purposes, achieving the desired surface attributes through techniques like sandblasting has become imperative.

The automotive industry in particular has raised the bar as far as exterior and interior looks are concerned. Car owners now expect flawless paint finishes, scratch-resistant coated trim pieces and finely sanded logos/texturing. Similarly, modern aircraft designs involve complex contours that mandate specialized preparation of metallic alloys through abrasive blasting before further coating. On the construction front, sandblasting lends durability and aesthetic appeal to building materials such as concrete, bricks, floor tiles etc. It creates microscopic surface roughness essential for ensuring adhesion of subsequent protective layers. All these end-use sectors have substantially higher quality standards today than in the past, placing greater technical requirements on preprocessing methods.

A direct consequence of the augmented quality demands across industries has been a surge in customization of sandblasting equipment. Machines now accommodate variable nozzle sizes, media types, pressures and automated controls to achieve consistent results on small batches of intricate parts. Portable, compact variants have also gained favor for on-site surface treatment of large structures. The growing preference for renting sandblasting units instead of capital expenditure additionally points towards an expanding addressed market. While basic blast cabinets suffice for low volume jobs, sophisticated robotic sandblasters are increasingly used in automated manufacturing lines to boost productivity.

Market Driver - Focus on Optimizing Surface Preparation Processes Encourages the Deployment

With current competitive pressures on manufacturers to lower costs and accelerate throughput, there is heightened focus on streamlining production workflows. An often-overlooked yet important step influencing overall efficiency is effective surface preparation prior to painting, coating, or other value-adding processes. Advanced surface preparation techniques ensure proper substrate readiness and adhesion of subsequent finishing layers as per quality norms and engineering specifications. Among available methods, sandblasting stands out for its versatility and reliability in achieving the targeted surface profile on a wide range of materials.

However, conventional manual sandblasting is labor-intensive with inherent inconsistencies. Seeking optimization, manufacturers now emphasize deploying technologically proficient surface treatment resources. Automated and robotic sandblasting systems in particular address issues of reproducibility and ergonomics. Such sophisticated machines allow for digital programming of variables to precisely control media flow, angle of impact and sweeping motion. They are useful in mass-producing identical components by ensuring uniform blasting across batches. The ability to be integrated seamlessly into automated production lines further increases their appeal. Additionally, dust extraction functionalities minimizes cleanup and improves plant occupational safety.

With the Industrial Internet of Things accelerating, there is a concurrent push towards smart connected equipment featuring remote monitoring capabilities. The benefits of condition-based predictive maintenance and data-based process enhancements are compelling manufacturers to upgrade existing sandblasting tools as well. They can leverage technologies such as sensors, software and AI to optimize surface preparation cycles and resources spent on them. All these evolving needs, from initial batch preparation to predictive upkeep, signify sandblasting machinery will remain central to forward-thinking manufacturers focused on reaping Industry 4.0 dividends.

Market Challenge - Environmental and Health Concerns Related to the Abrasive Materials Used in Sandblasting Processes, Leading to Regulatory Challenges and Higher Costs For Compliance

One of the major challenges faced by the sandblasting machines market is the environmental and health concerns related to the abrasive materials used in sandblasting processes. Sandblasting involves the use of abrasive materials like silica sand, aluminium oxide, garnet and glass beads which pose serious health hazards. Prolonged exposure to these materials can cause respiratory illnesses like silicosis. There are also environmental concerns regarding the waste generated during sandblasting containing toxic materials. Strict regulations have been imposed in many countries regarding the use, handling and disposal of these abrasive materials. Companies operating in the sandblasting machines market have to comply with various norms for dust extraction and filtration. This leads to higher compliance costs for vendors. Overall, the regulatory challenges arising from environmental and health risks associated with abrasive materials used in sandblasting pose a major hurdle for the growth of sandblasting machines market.

Market Opportunity- Increasing Infrastructure Investments Fuels the Industry Growth

One significant opportunity for the sandblasting machines market is the rising infrastructure investments, particularly in developing nations. Sandblasting finds wide application in cleaning and preparing surfaces for painting, coating and other applications in construction industry. The ongoing infrastructure boom in Asia Pacific and Middle East countries is driving large number of projects in sectors like transportation, energy and buildings. This is expected to generate substantial demand for surface preparation activities including sandblasting. The growing construction activities are projected to boost the sales of sandblasting machines in the coming years. Market players could leverage the infrastructure-led economic growth in emerging markets to increase their revenues.