South Korea Methyl Methacrylate (MMA) Market SIZE AND SHARE ANALYSIS - GROWTH TRENDS AND FORECASTS (2024 - 2031)

South Korea Methyl Methacrylate Market is Segmented By Application (Chemical Intermediate, Surface Coating, Others), By End-use Industry (Building & C....

South Korea Methyl Methacrylate (MMA) Market Size

Market Size in USD Mn

CAGR6.00%

| Study Period | 2024 - 2031 |

| Base Year of Estimation | 2023 |

| CAGR | 6.00% |

| Largest Market | South Korea |

| Market Concentration | High |

| Major Players | BASF SE, Evonik Industries AG, Arkema Group, The Dow Chemical Company, Sumitomo Chemical Company Limited and Among Others. |

please let us know !

South Korea Methyl Methacrylate (MMA) Market Analysis

The South Korea Methyl Methacrylate Market is estimated to be valued at USD 581.6 Mn in 2024 and is expected to reach USD 872.0 Mn by 2031, growing at a compound annual growth rate (CAGR) of 6.00% from 2024 to 2031.

The demand for methyl methacrylate is expected to increase steadily during the forecast period.

South Korea Methyl Methacrylate (MMA) Market Trends

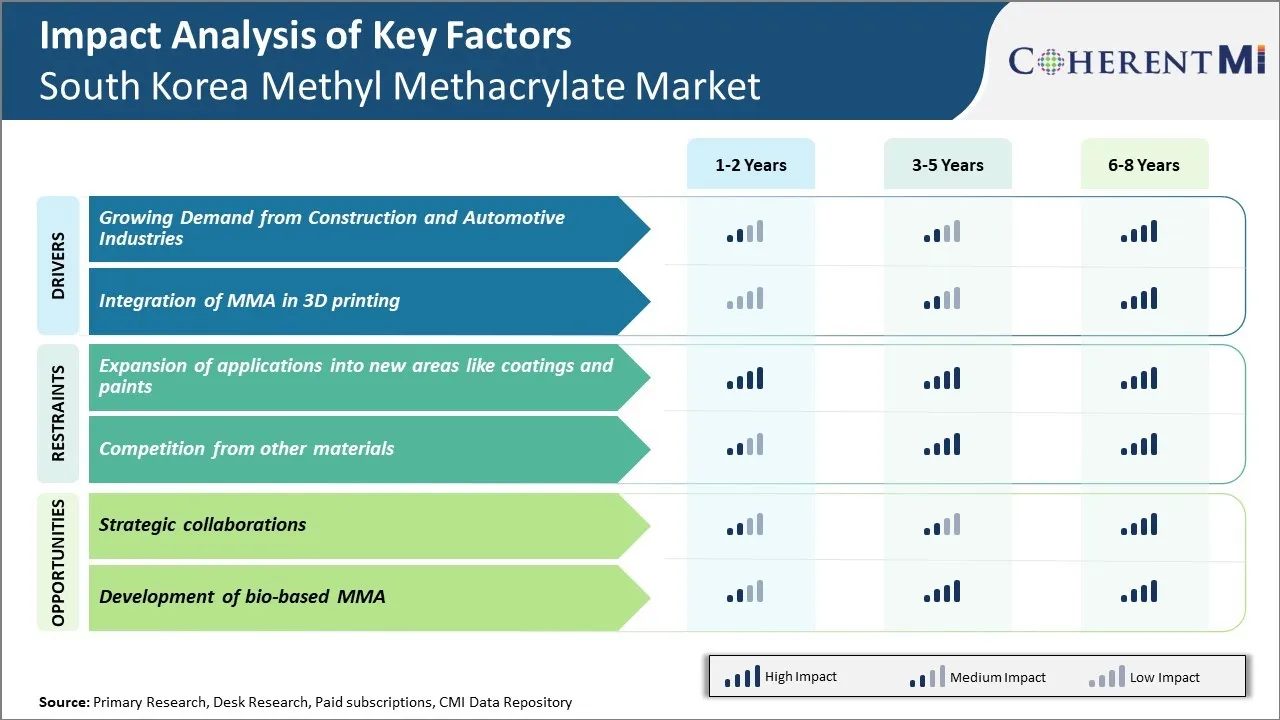

Market Driver – Growing Demand from Construction and Automotive Industries

The construction and automotive industries in South Korea have been experiencing steady growth in recent years, which has significantly boosted the demand for methyl methacrylate. Methyl methacrylate is a key raw material used in manufacturing polymethyl methacrylate (PMMA), which finds extensive applications in these industries.

In the construction sector, PMMA has emerged as a popular alternative to traditional materials like glass and steel due to its advantageous properties such as light weight, durability, and resistance to extreme weather conditions. Major infrastructure projects undertaken by the government such as new urban developments, bridges, tunnels, and metro systems have increased the consumption of PMMA sheets for glazing and roofing applications. According to statistics by the Ministry of Land, Infrastructure and Transport, Korea, construction investment grew by 5.2% year-on-year to KRW 129.4 trillion in 2020 driven by private sector housing and public works. This upward trend is likely to continue with ongoing urbanization across the country. The construction and automotive industries in South Korea have been experiencing steady growth in recent years, which has significantly boosted the demand for methyl methacrylate.

Market Driver – Integration of MMA in 3D Printing

The integration of MMA in 3D printing applications has opened up new growth opportunities for the South Korea MMA market. MMA is widely used as a main raw material in the production of polymethyl methacrylate (PMMA), which finds extensive application in 3D printing due to its transparency, stiffness and durability. Over the past few years, 3D printing has experienced heightened adoption across various industries in South Korea, such as automotive, aerospace, healthcare and consumer goods. This has substantially increased the demand for high-quality photopolymers that can deliver precision and accuracy in the final 3D printed components. PMMA tailored for 3D printing applications has emerged as one of the preferred polymers due to its UV light curability and capability to produce transparent and functional parts.

Moreover, continued technological advancements are expanding the scope of PMMA 3D printing to produce prototypes and end-use products for new potential sectors. For instance, researchers at Daegu Gyeongbuk Institute of Science and Technology have developed bio-compatible PMMA materials for 3D printing medical implants and prosthetics (DGIST, 2022).

Market Challenge – Expansion of Applications Into New Areas Like Coatings and Paints

The expansion of methyl methacrylate (MMA) applications into new areas like coatings and paints is creating regulatory hurdles that are restraining the growth of South Korea's MMA market. As MMA is increasingly being used as a replacement for toxic solvents in paints and coatings, issues around VOC emissions have come under scrutiny. According to data from the Korean Ministry of Environment published in 2022, MMA releases volatile organic compounds (VOCs) that contribute to the formation of ground-level ozone and smog. While its VOC emissions are lower than traditional solvents, the rapidly growing use of MMA in decorative and automotive paints has led to a rise in total VOC emissions from this sector.

This has prompted the South Korean government to propose tighter VOC regulations for MMA-based paints and coatings. In 2021, the Ministry of Environment announced plans to lower the allowable VOC content from the current level of 450 grams per liter to 400 grams by 2023. This would bring the limits in line with rules in Japan and China.

Market Opportunity – Strategic Collaborations

The expansion of methyl methacrylate (MMA) applications into new areas like coatings and paints is creating regulatory hurdles that are restraining the growth of South Korea's MMA market. As MMA is increasingly being used as a replacement for toxic solvents in paints and coatings, issues around VOC emissions have come under scrutiny. According to data from the Korean Ministry of Environment published in 2022, MMA releases volatile organic compounds (VOCs) that contribute to the formation of ground-level ozone and smog.

This has prompted the South Korean government to propose tighter VOC regulations for MMA-based paints and coatings. In 2021, the Ministry of Environment announced plans to lower the allowable VOC content from the current level of 450 grams per liter to 400 grams by 2023. This would bring the limits in line with rules in Japan and China. Additionally, regulations limiting ground-level ozone and smog concentrations are also proposed in major cities like Seoul, Busan and Incheon by 2025 based on WHO guidelines according to a 2022 report by the Korean Ministry of Environment.

Segmental Analysis of South Korea Methyl Methacrylate (MMA) Market

Insights, By Application: Rising Demand for Chemical Intermediate

The chemical intermediate segment dominates the South Korea methyl methacrylate market with a market share of 58.4% due to robust demand from downstream industries. As a key building block in industrial chemical synthesis, methyl methacrylate finds wide application as an intermediate in producing polymethyl methacrylate (PMMA) and methacrylate polymers. PMMA, commonly known as acrylic glass, enjoys vast usage in signage, construction, sanitary ware and optical applications. Its excellent thermoformability, optical clarity and weather resistance have led to surging demand from South Korea's fast-growing construction and infrastructure industries.

Additionally, methyl methacrylate acts as an intermediate in manufacturing a variety of chemically synthesized products like synthetic rubbers, coatings, adhesives and personal care products. The rapid expansion of South Korea's automotive, electronics and pharmaceuticals sectors in recent years has substantially increased consumption of methyl methacrylate-derived chemicals. Moreover, the growing preference for green chemistry is propelling research on bio-based methyl methacrylate routes that utilize renewable feedstocks. The promising outlook of downstream methyl methacrylate-consuming segments will continue to drive its uptake as a key chemical building block.

Insights, By End-use Industry: Building & Construction Sector Catalyzes South Korea Methyl Methacrylate Demand

The building & construction industry dominates by 41.5% market share in South Korea methyl methacrylate market, owing to its extensive applications in this end-use segment. Methyl methacrylate monomers and polymers are widely used in various construction materials and composites manufacturing. PMMA sheets find immense usage in interior and exterior architectural applications like skylights, canopy sheets, parapet walls and balcony railings because of their superior light transmission, weather resistance and economical cost relative to glass. Additionally, methyl methacrylate based polymeric concretes and mortars provide excellent strength, durability and water resistance properties for infrastructure works.

South Korea has also witnessed tremendous growth in its real estate and infrastructure development activities over the past decade. Mega projects for developing smart cities, industrial complexes, transportation hubs, residential townships and commercial spaces have fueled the demand for advanced construction materials. The strong emphasis on sustainable building practices is also driving consumption of wood-plastic composites and fiber reinforced polymers manufactured using methyl methacrylate polymers.

Competitive overview of South Korea Methyl Methacrylate (MMA) Market

The major players operating in the South Korea Methyl Methacrylate Market include BASF SE, Evonik Industries AG, Arkema Group, The Dow Chemical Company, Sumitomo Chemical Company Limited, Korea Petrochemical Ind. Co., Ltd. (KPIC), Lotte Chemical Corporation, Mitsubishi Chemical Corporation (MCC), LG Chem, and Hanwha Chemical Corporation.

South Korea Methyl Methacrylate (MMA) Market Leaders

- BASF SE

- Evonik Industries AG

- Arkema Group

- The Dow Chemical Company

- Sumitomo Chemical Company Limited

South Korea Methyl Methacrylate (MMA) Market - Competitive Rivalry, 2024

South Korea Methyl Methacrylate (MMA) Market

(Dominated by major players)

(Highly competitive with lots of players.)

Recent Developments in South Korea Methyl Methacrylate (MMA) Market

- In October 2023, BASF in Korea started to supply biomass balanced MDI, paving the way for a sustainable MDI value chain.

- In August 2023, Evonik signed an agreement to scale up and produce custom catalyst for Röhm’s new methyl methacrylate (MMA) production plant.

- In December 2020, Arkema announced the proposed divestment of its MMA business to Trinseo for an enterprise value of €1,137 million. This project is a new step in the Group’s transformation and is fully in line with Arkema’s ambition to become a pure Specialty Materials player by 2024.

- In February 2022, Sumitomo Chemical decided to establish a new MMA Division as of April 1, 2022, to strengthen its MMA business, which includes MMA (methyl methacrylate) monomer and acrylic resin (PMMA, polymethyl methacrylate). The new division will take charge of strategy formulation and global marketing and sales for the business as a whole.

South Korea Methyl Methacrylate (MMA) Market Segmentation

- By Application

- Chemical Intermediate

- Surface Coating

- Others (Emulsion Polymer)

- By End-use Industry

- Building & Construction

- Automotive

- Electronics

- Paints & Coatings

- Others (Aerospace, etc.)

Would you like to explore the option of buying individual sections of this report?

Frequently Asked Questions :

What are the key factors hampering the growth of the South Korea Methyl Methacrylate Market?

The expansion of applications into new areas like coatings and paints and competition from other materials are the major factors hampering the growth of the South Korea Methyl Methacrylate Market.

What are the major factors driving the South Korea Methyl Methacrylate Market growth?

The growing demand from construction and automotive industries and integration of MMA in 3D printing are the major factors driving the South Korea Methyl Methacrylate Market growth.

Which is the leading Application in the South Korea Methyl Methacrylate Market?

The leading Application segment is Chemical Intermediate.

Which are the major players operating in the South Korea Methyl Methacrylate Market?

BASF SE, Evonik Industries AG, Arkema Group, The Dow Chemical Company, Sumitomo Chemical Company Limited, Korea Petrochemical Ind. Co., Ltd. (KPIC), Lotte Chemical Corporation, Mitsubishi Chemical Corporation (MCC), LG Chem, and Hanwha Chemical Corporation are the major players.

What will be the CAGR of the South Korea Methyl Methacrylate Market?

The CAGR of the South Korea Methyl Methacrylate Market is projected to be 6.0% from 2024-2031.