3D Metrology Market Trends

Market Driver - Increasing Adoption of 3D Modeling Across Industries

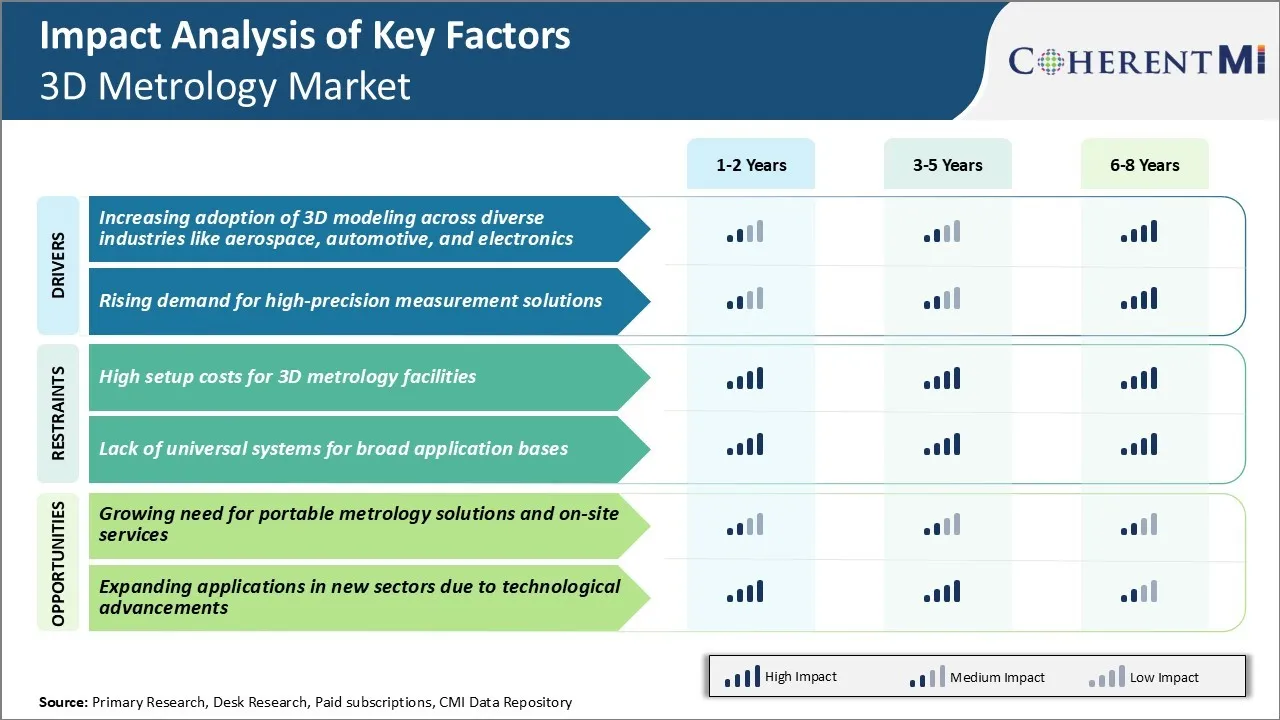

The use of 3D modeling techniques has seen widespread growth across major industries like aerospace, automotive and electronics in recent years. Automakers are extensively using 3D CAD/CAM software to design vehicles with advanced functionalities in a virtual environment before production. Similarly, aerospace manufacturers are extensively adopting 3D modeling as aircraft systems have become more complex with integrated avionics, sensors and thousands of parts. Likewise, electronics manufacturers are relying on 3D CAD software to design circuit boards and components with greater precision.

Many large automotive outfits have set up dedicated digital engineering centers focused on 3D modeling of vehicles from scratch. Aerospace manufacturers are allocating greater budgets towards advanced CAE solutions to integrate design, analysis, simulation and manufacturing using a common 3D database. Even electronics companies are establishing virtual product development labs with sophisticated modeling workstations to accelerate time-to-market for new-age consumer devices.

Overall 3D modeling is increasingly becoming the default approach for conceiving and realizing innovative product designs across a wide spectrum of industries, driving the 3D metrology market.

Market Driver - Rising Demand for High-Precision Measurement Solutions

With the growing complexity of manufactured components, the requirements from quality control and inspection processes are also becoming stricter. Products across industries need to meet very tight tolerances, have fine surface finishes and demand high levels of dimensional accuracy during production. Ensuring quality and reliability of such precision-engineered goods calls for sophisticated metrology systems adept at high-resolution inspection.

In order to keep pace with such exacting quality standards, manufacturers are increasingly automating metrology operations and augmenting manual inspection techniques with digitized 3D measurement solutions. Coordinate measuring machines equipped with non-contact probes offering resolution in single-digit microns are being deployed on production floors for inline inspection.

Demand for advanced metrology solutions delivering high measurement accuracy, repeatability, and throughput is witnessing steady gains. This presents broad-based opportunities for 3D scanning and metrology companies to develop specialized solutions catering to emerging needs across verticals.

Market Challenge - High Setup Costs for 3D Metrology Facilities

One of the key challenges faced by the 3D metrology market is the high setup costs associated with establishing 3D metrology facilities. Setting up advanced 3D metrology equipment requires significant capital investments. In addition to the equipment costs, 3D metrology facilities also require suitable infrastructure.

Major requirements include temperature-controlled laboratories, stable power supply, qualified technical staff for operating and maintaining the systems, as well as periodic system calibration. All these factors contribute to high fixed setup costs. This poses a significant barrier for small and mid-sized manufacturing companies to invest in their own in-house 3D metrology capabilities.

The high costs encourage these companies to rely more on third-party metrology service providers for their inspection and reverse engineering needs. However, this option may not always be cost-effective compared to owning the systems. The high initial investments are thus a major challenge restraining the growth of the 3D metrology market, especially among small enterprises.

Market Opportunity - Growing Need for Portable Metrology Solutions and On-site Services

One major opportunity for the 3D metrology market is the growing need for portable metrology solutions as well as on-site metrology services among manufacturers. There is an increasing demand from manufacturers to perform dimensional inspections directly on the shop floor near the point of production to minimize work-in-process handling. This has fueled the demand for portable, handheld 3D metrology systems that can be easily moved around the factory floor.

Industries are also increasingly adopting metrology services provided on-site by third-party 3D metrology companies to overcome the challenges of high capital investment and dedicated lab space. The need for portable and on-site metrology is anticipated to grow further with the advancement of Industry 4.0 trends such as smart factory and connected products. This presents a major opportunity for 3D metrology market players to expand their offerings of portable CMMs, scanners, microscopes as well as value-added on-site metrology services.