Aseptic Filling Machines Market Trends

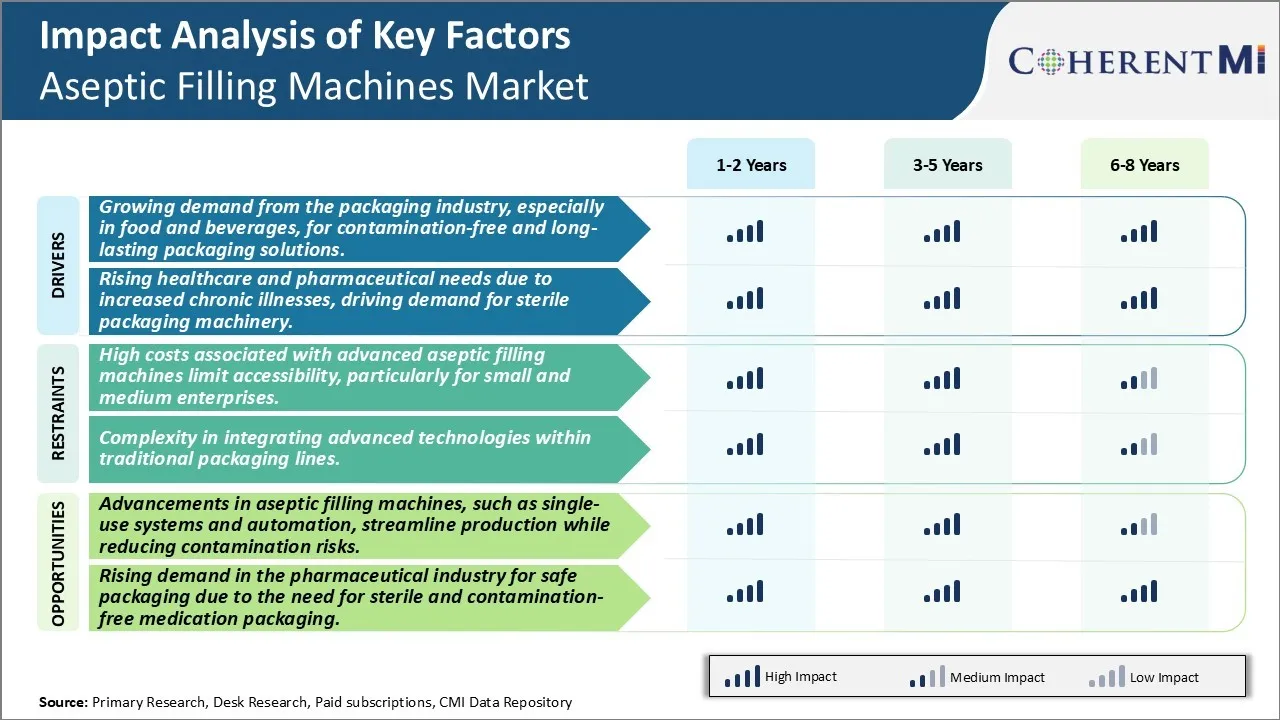

Market Driver - Growing Demand from Packaging Industry, Especially in Food and Beverages, for Contamination-Free and Long-Lasting Packaging Solutions

The packaging industry has been growing at a robust rate over the past decade driven primarily by the rapidly expanding food and beverage industry. Consumer preference for fresh, preservative-free and ready-to-eat food products has strengthened the business case for aseptic filling machines that can fill products in a sterile environment and seal them securely for a longer shelf life without refrigeration. Companies have recognized this consumer behavior and are extensively investing in packaging technologies that can deliver optimal product protection during storage, distribution and retail stages.

Aseptic filling machines serve this need perfectly through their ability to conduct the entire filling process within an enclosed and sterilized aseptic chamber. This limits product contamination risks to almost zero levels, allowing packaged items to retain their organoleptic and nutritional qualities for 3 to 6 months even without chilling. Drinks, milk, sauces, concentrates are some products that have immensely benefited from aseptic processing. Machine manufacturers are also coming up with advanced aseptic fillers that maximize packaging line speed and output volumes to aid higher producer efficiencies. Their automated design requires less manual intervention further improving hygiene standards.

Rising investments in new product formulations tailored for convenient consumption have additionally augmented demand for sterile filling machinery. Examples include nutritious liquid meals or probiotic drinks that need contamination-free conditions from packing to usage. Moreover, with global trade increasing, packages require longer preservation capability throughout intercontinental transportation as well. Aseptic lines address this critical requirement and have stimulated wider relevance across sauces, dressings and other food categories too. All such macro factors are driving relentless packaging line modernization worldwide and propelling aseptic filling machinery uptake in the foreseeable future.

Market Driver - Rising Healthcare Needs Contributes to the Industry Growth

The rapid aging of population profiles and increasing prevalence of chronic health conditions like diabetes, cardiac problems and obesity have greatly expanded the pharmaceutical market scope. A large share of this rise stems from enhanced treatment needs for such non-communicable lifestyle diseases rather than infectious ailments. Sterility consequently becomes a paramount packaging requirement for ensuring medication safety, purity and branded trustworthiness throughout extended supply chains.

Aseptic filling machines perfectly cater to these stringent industry sterility norms as they can seal parenteral, biological and other medical products absolutely freed from microbial or external particle contamination risks. Their enclosed system design precludes any contact between the product and surrounding environment, maintaining product integrity from filling to capping. Moreover, their high-speed performance and automated operation lower processing costs of vaccines, infusions and other therapies in high demand.

Governments worldwide have also been prioritizing improved access to affordable healthcare via initiatives like universal coverage programs. This has bolstered the volumes of anti-diabetics, antipsychotics, antihypertensives and other chronic ailments drugs to be supplied through large-scale domestic distribution channels. Aseptic machines thereby emerge as a lucrative technology investment for guaranteeing stable supply of quality medicines at population scale. Their cleanroom-compliant configurations further facilitate strict compliance with regulating authorities like US FDA or EU CGMP mandates.

In conclusion, the inexorable growth trends in both pharmaceuticals and packaging sectors are expected to consistently fuel the adoption of aseptic filling lines globally. Their superior sterility safeguarding functionality is ideally aligned to fulfill future industry and social needs surrounding health, convenience and product protection.

Market Challenge - High Costs Associated with Advanced Aseptic Filling Machines Limit Accessibility, Particularly for Small and Medium Enterprises

The aseptic filling machines market faces significant challenges due to the high costs associated with advanced aseptic filling technology. The sophisticated automated machinery and stringent validation protocols required for aseptic processing come with a substantial price tag. Established players in the market offer turnkey aseptic lines that can exceed seven-figure price points. While necessary for large pharmaceutical manufacturers to ensure sterility and shelf life of sensitive drug products, these capital expenditures place aseptic solutions out of reach for many small and medium enterprises. Cost prohibitive machinery obstructs access to new entrants in the market and hampers the ability of smaller players to scale production in a sterile environment. This disproportionately impacts developers of generic drugs, biosimilars and other smaller volume products. Achieving aseptic processing requires commitment of sizable resources that smaller companies may not have accessibility to. The high barrier of entry protects market share of existing industry giants but slows innovation and competition from startups or region-specific manufacturers.

Market Opportunity: Advancements In Aseptic Filling Machines, Such as Single-Use Systems and Automation, Streamline Production While Reducing Contamination Risks

The aseptic filling machines market is primed for growth due to technological advancements that enhance capabilities while lowering costs. Emerging solutions such as single-use disposable systems eliminate the need for capital-intensive sterilization cycles between product changeovers. Their disposable nature increases speed to market for new products and gives manufacturers flexibility to scale operations efficiently. Automation is also reducing manual intervention and contamination hazards during aseptic processing. Advances in robotics, computer vision and other enabling technologies optimize manufacturing flows to minimize contamination risks. Such innovations streamline production processes for aseptic filling. They allow smaller companies to achieve terminal sterilization standards more affordably while large players benefit from increased efficiency. The opportunities presented through modernization of technology are driving market players to invest in solutions that balance stringent safety with scalability and reduced total cost of ownership over the long-term.