Automotive Differential Market Trends

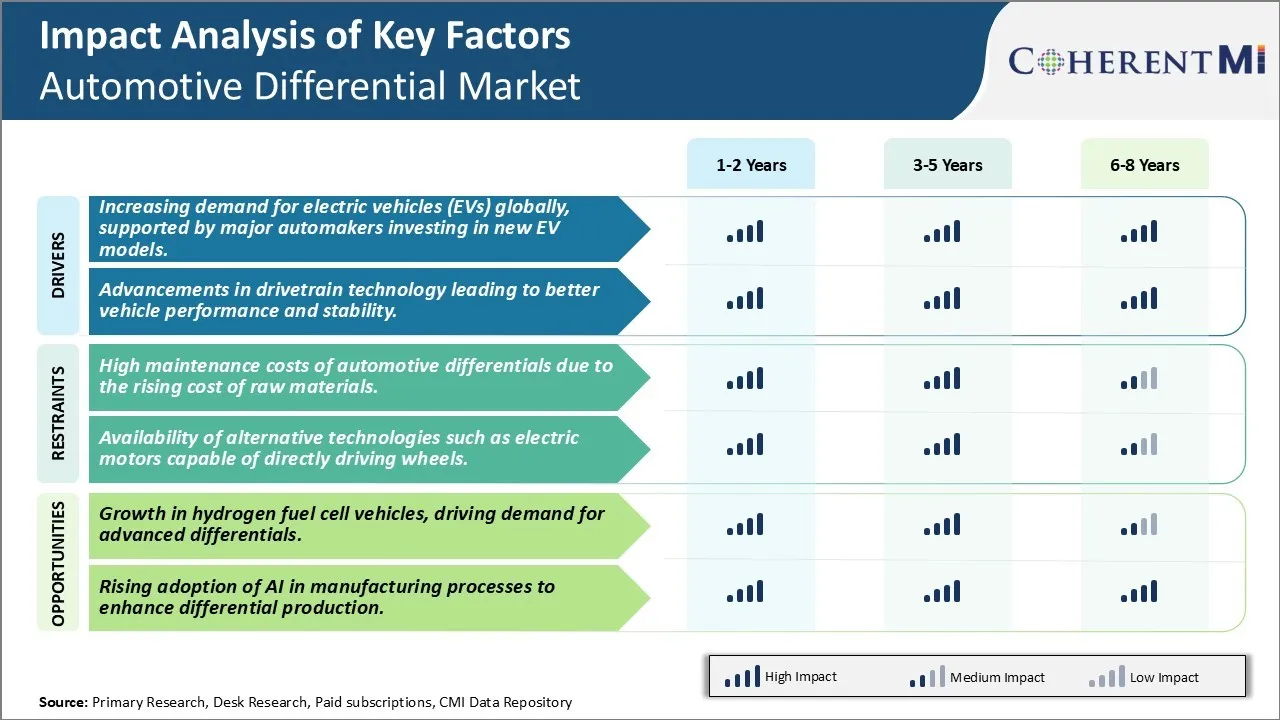

Market Driver - Increasing Demand for Electric Vehicles (EVs) Globally, Supported by Major Automakers Investing in New EV Models

The automotive industry has seen a major shift towards electrification in recent years. Stringent emission norms around the world are pushing automakers to invest heavily in the development of electric vehicles. Most top automakers like Volkswagen, GM, Ford, and Nissan have announced bold electric vehicle plans and lineups. They aim to launch multiple affordable long-range EV models over the next five years to capitalize on the growing market opportunity.

Consumer preference for electric vehicles is also rising considerably due to lowered total cost of ownership compared to gasoline vehicles. EV maintenance and fuel costs are significantly lower which appeals to environmentally conscious customers. Further, many countries offer attractive purchase incentives and tax rebates for electric vehicles to accelerate their adoption. Rising environmental awareness among people is augmenting the demand for clean emissions-free transportation alternatives. Gasoline prices too have witnessed fluctuations which make operating costs of EVs more predictable in the long run.

The strong policy push for electric mobility is compelling major automakers to pour billions of dollars into battery and electric powertrain technologies. New factories are being set up for large-scale production to meet demand. However, designing electric powertrains poses unique engineering challenges compared to traditional internal combustion engines. Advanced components like the electric motor, battery management systems, and differentials need continuous innovation. Auto components manufacturers are gearing up to cater to this transition in a big way. The differential market is expected to play a vital role in the seamless operation of electric drivetrains and ensuring optimal performance and efficiency.

Market Driver: Advancements in Drivetrain Technology is Shaping the Trends in Automotive Industry

The automotive industry is continuously working towards enhancing the performance, efficiency and driving dynamics of vehicles. Advancements in materials, design and manufacturing are allowing automakers to build more powerful yet efficient drivetrains. Modern vehicles are expected to deliver high torques instantly, adaptive responses on different surfaces and seamless transmission of power generated. This pushes auto component suppliers to innovate continuously.

Differentials play a crucial role in distributing drive torque unequally between the wheels for optimal traction and stability. Traditional open and locked differential designs have limitations. The need for advanced torque vectoring capabilities is driving developments in multi-plate and clutch-based limited slip differential technologies. These allow very fast and adaptive control of torque distribution according to driving conditions. They ensure stability even under challenging scenarios like acceleration on wet or slippery surfaces where one wheel may lose traction temporarily.

At the same time, improvements in transmission design are complementing the drivetrain's performance capabilities. New dual-clutch and continuously variable transmission solutions enable faster gear shifts compared to conventional automatic transmissions. Combining them with state-of-the-art differentials contributes to sharper acceleration, better handling and fuel efficiency. The integration of driver-assist systems further requires differentials to work in tandem with other components like electric power steering for accurate torque vectoring responses. All these technologically enabled capabilities are enhancing the holistic driving experience considerably. Consequently, it is raising performance standards for drivetrain suppliers globally.

Market Challenge - High Maintenance Costs of Automotive Differentials Due to the Rising Cost of Raw Materials

The automotive differential market faces significant challenges from the rising costs of raw materials required for differential manufacturing. Raw materials like steel, aluminum, and specialized alloys are crucial components of differential assemblies. However, prices of these metals have increased substantially in recent years. Steel prices, in particular, have risen by over 30% since 2020 due to shortages and higher production costs. Aluminum prices have also risen steadily, driven by growing demand from several industries including automotive, construction and consumer durables. The supply chain disruptions caused by the COVID-19 pandemic have further exacerbated raw material price volatility and supply inconsistencies.

Higher raw material prices have directly impacted the maintenance and repair costs for differentials. Manufacturers have been forced to pass on some of the increased raw material costs to customers in the form of higher differential component and assembly prices. This has made routine repairs and replacements more expensive for vehicle owners. The need to replace damaged differential components also arises more frequently as vehicles age. The combination of rising component prices and greater repair needs has inflated the overall cost of differential maintenance significantly. Unless raw material price stabilization measures are implemented, maintenance cost burden will continue climbing. This could negatively impact consumer demand and undermine the price competitiveness of automakers.

Market Opportunity: Growth of Hydrogen Fuel Cell Vehicles Encourages Industry Developments

The increasing focus on developing hydrogen fuel cell vehicles presents a major opportunity for differential manufacturers to supply advanced components tailored for these upcoming platforms. Fuel cell vehicles require highly specialized electric powertrains and differentials engineered to handle the unique power characteristics of hydrogen fuel cells. Their differentials need to efficiently distribute torque generated by fuel cell-electric powertrains across multi-wheel architectures. Leading automakers are aggressively investing in fuel cell technology to launch commercial vehicles within this decade. This will drive the need for differentials with advanced attributes like high torque capacity, compact dimensions optimized for fuel cell packaging, lightweight yet durable materials, and power electronics integration capabilities.

Differential suppliers experienced in developing electric vehicle components have an advantage in securing large supply contracts. Capturing early mover positions in hydrogen vehicle differentials allows manufacturers to establish product reliability and branding. It also provides an opportunity to drive innovation through next-gen materials, integrated motor solutions and technologies tailored for commercial vehicle duty cycles. Successful hydrogen vehicle programs could open up a huge new market for advanced differentials, acting as a catalyst for long term revenue growth.