Automotive Steel Wheels Market Trends

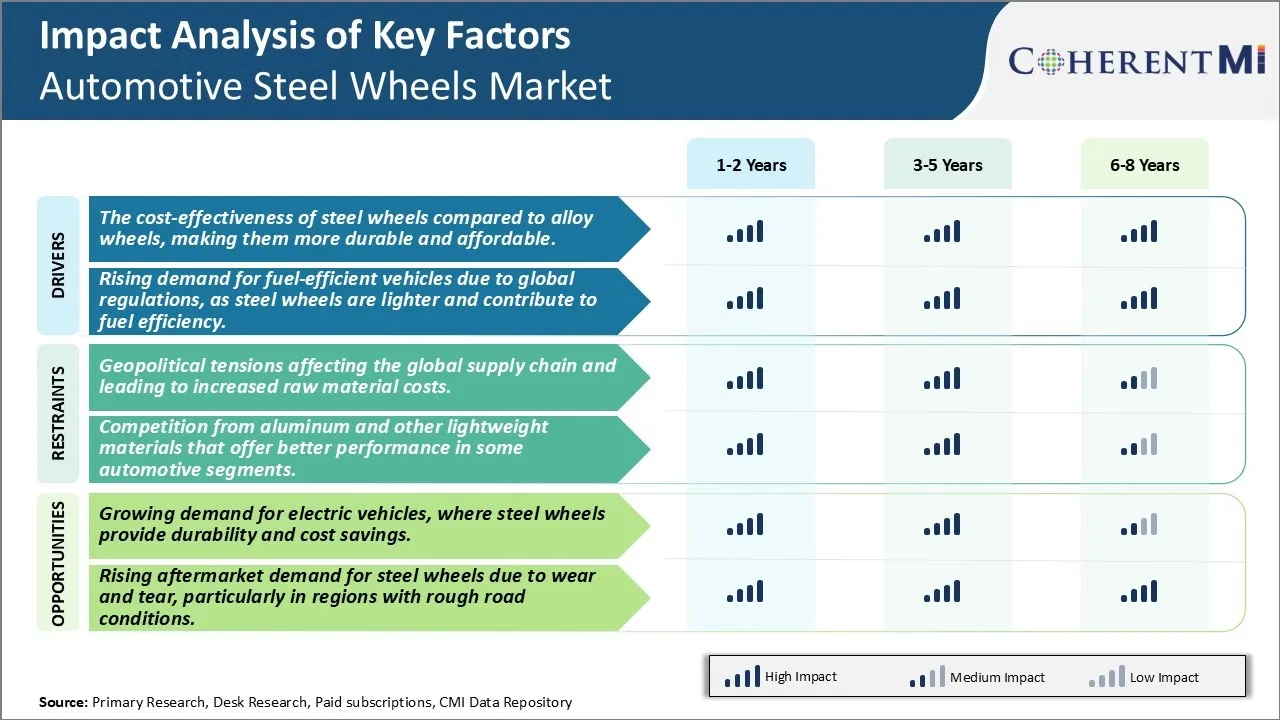

Market Driver - The Cost-Effectiveness of Steel Wheels Compared to Alloy Wheels, Making Them More Durable and Affordable

Steel wheels represent a highly cost-effective solution for automakers compared to alloy wheels. Being significantly cheaper to produce than alloy wheels means that automakers are able to offer them as a standard fitment on many entry-level and economy models. This helps keep the initial purchase price of such vehicles low and makes them affordable for many price-sensitive consumers. Steel wheels are often nearly half or even a third of the price of a comparable set of alloy wheels. The lower costs are passed down to the end customer, making steel-wheeled variants of vehicles much more accessible financially.

Additionally, steel wheels are known to withstand daily wear and tear quite well. While they may not look as flashy as alloy wheels, they can endure curb rash, pothole impacts and minor accidents much better without needing replacement. This translates to lower ownership costs over the long run for buyers. Steel also does not corrode or get damaged like cheaper alloys sometimes do. As a result, steel wheels tend to have a longer service life, often lasting the entire lifespan of the vehicle if properly maintained. This minimizes unplanned wheel replacement expenses and helps keep total cost of ownership lower.

Market Driver - Rising Demand for Fuel Efficient Vehicles Boosts Market Growth

Tightening emissions regulations around the world have put immense pressure on automakers to improve the efficiency and reduce the environmental impact of their vehicles. One way they are addressing this is by focusing more on weight savings throughout the vehicle, including the wheels. Steel wheels contribute to this goal as they are significantly lighter than alloy wheels of a similar design. Every extra ounce saved can help boost overall fuel economy marginally. For example, a set of steel wheels may weigh up to 10-20 lbs less than an aluminum alternative. Considering millions of vehicles are sold each year globally, the microscopic improvements add up substantially. Automakers are able to claim better fuel efficiency ratings and meet stringent new testing protocols partly because of the use of steel wheels. This has benefits for both manufacturers and consumers. The industry can avoid hefty fines for being non-compliant, while customers benefit from lower fuel bills. With fuel prices only moving higher, buyers are increasingly factoring running costs into their purchasing decisions. Steel wheels thus improve the value proposition of many mainstream models in light of rising demand for thriftier motoring.

Market Challenge - Geopolitical Tensions Affecting the Global Supply Chain and Leading to Increased Raw Material Costs

Geopolitical tensions between major trading partners have escalated in recent years, disrupting global supply chains for automotive steel wheels. Raw materials like steel and aluminum are facing significant cost pressures as trade disagreements raise tariffs and create non-tariff barriers. Several steel producing nations have become less reliable suppliers due to the prevailing political atmosphere. With steel being a bulk commodity that is difficult to locally source in many markets, wheel manufacturers have limited options for alternatives and must absorb these additional costs. The profit margins for steel wheels, which are highly commoditized, provide little flexibility when input costs surge. Supply chain risks have increased as well from potential conflicts or sanctions that could cut off critical material streams. Unless geopolitical stability can be restored through cooperative trade policies, cost pressures on raw materials will persist and potentially force wheel producers to raise prices.

Market Opportunity- Growing Demand for Electric Vehicles Presents an Opportunity

The rapid electrification of the automotive industry presents a major opportunity for steel wheel suppliers. As electric vehicles continue to gain broader market acceptance, steel wheels provide durability and cost savings advantages over more expensive alloy wheels. With their inherent weight benefits over alternatives, steel wheels allow EV manufacturers to extend vehicle range at a relatively low price point. Given battery costs and infrastructure challenges, getting the most possible distance per charge remains a key selling feature. Furthermore, the heavier electric powertrains require more robust suspension components, an area where steel excels. Suppliers that can demonstrate the energy efficiency and value proposition of pairing steel wheels with EVs may capture market share as this ambitious sector booms. Technological solutions maximizing these attributes open the door for expanded use of steel wheels in tomorrow's automobiles.