Brewery Equipment Market Trends

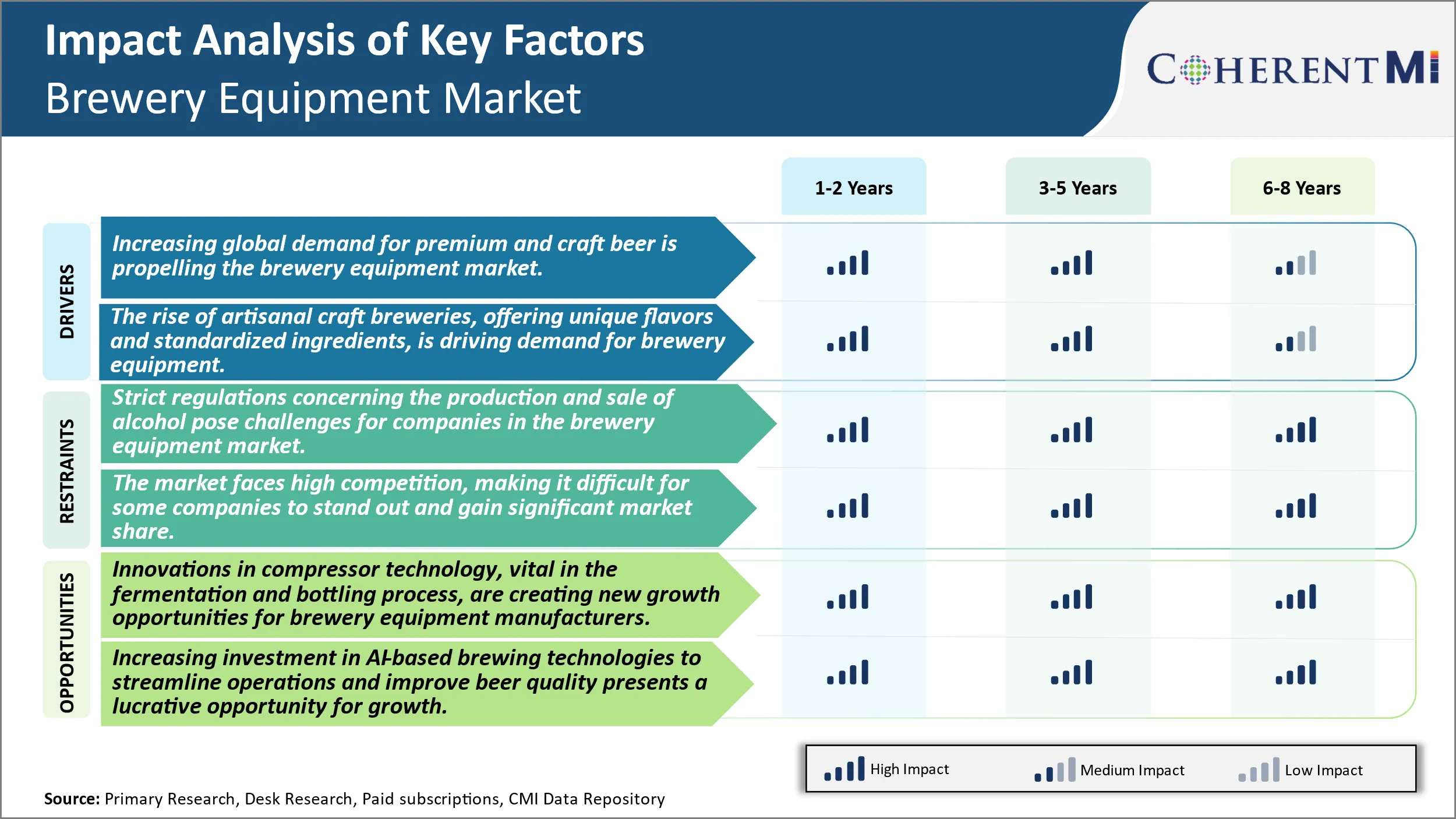

Market Driver - Increasing Global Demand for Premium and Craft Beer is Propelling the Brewery Equipment Market

The global appetite for craft and premium beers has been steadily rising in the last few years. Consumers today are more quality and variety-conscious when it comes to beer. They are moving away from the standard lagers and ales towards specialized craft beers featuring unique flavors, ingredients and brewing processes. This adventurous taste is translating into increasing sales and production volumes for premium and craft beers globally. As per industry estimates, the craft beer segment accounted for over 20% of the global beer market in 2021 and is expected to keep outpacing the growth of the overall beer industry.

The demand uptick has encouraged many large brewers to enter the premium brewing space or make acquisitions in the craft beer segment. It has also led to the rise of many new microbreweries and craft beer manufacturers particularly in Europe, North America and Asia Pacific. These premium and craft brewers require specialized equipment to deliver the variety, quality and customization today's discerning beer drinkers demand. Unlike the standardized equipment used by many mainstream brewers, craft breweries employ unique small-scale systems to experiment with diverse ingredients, brewing methods and flavors. Equipment such as craft brew house systems, fermenters, brite beer tanks and bottling lines allow them to scale up production of their niche craft beers.

Larger and well-established brewers are also investing in specialized craft systems to complement their existing portfolios and tap into the lucrative premium market. They need customized equipment at different brewing facilities to brew special seasonal, small-batch beers for local markets. Meanwhile, the thriving microbrewery culture has prompted the entry of many new craft brewers who rely solely on premium equipment right from their startup. With many nations also liberalizing regulations to promote local craft brewing, the demand for versatile brewery equipment enabling unique brewing capabilities continues to surge. This rising global appetite for premium and specialty craft beers is thus a major driver propelling the sales and growth of the brewery equipment industry.

Market Driver - The Rise of Artisanal Craft Breweries Fuels Demand for Brewery Equipment

In the last decade, there has been a groundswell of small independent artisanal breweries popping up globally. Discerning consumers are displaying a growing appreciation for authentic beers brewed in small batches with unconventional ingredients and distinct flavors. This consumer shift has provided the impetus for many entrepreneurs and experienced brewers to establish microbreweries producing premium specialty beers. These boutique craft breweries offer a highly localized, customized beer-making experience using standardized organic ingredients and eco-friendly brewing methods.

Notable aspects of the artisanal brewing model include reliance on local sourcing of barley, hops and fruits, unique brewing techniques and constant innovation of new seasonal beers. Most microbreweries also highlight the provenance of ingredients and brewing process as a mark of their distinct identity. Their brews therefore possess an inherent sense of place celebrated by local communities. Besides appealing to gourmet tastes, artisanal beers also represent nostalgia for old world brewing traditions and ethically produced food and beverages. This convergence of quality, authenticity and sustainability has won craft breweries legions of loyal fans globally.

The proliferation of artisanal microbreweries has boosted demand for specialized equipment needed to deliver their signature brews consistently while upholding high production standards. These include compact brew house systems, fermenters suited to small batch sizes, versatile vessels and innovative packaging lines. Many craft brewers also require mobile canning or bottling solutions for flexibility. Overall, the global rise of the artisanal brewing model presents a key tailwind driving increased investments in specialized brewery equipment tailored for niche craft beer production. This trend is expected to solidify further as consumer emphasis on provenance and unique gastronomic experiences grows worldwide.

Market Challenge - Strict Regulations Concerning the Production and Sale of Alcohol Pose Challenges for Companies in the Brewery Equipment Market

Strict regulations concerning the production and sale of alcohol pose challenges for companies in the brewery equipment market. Various government bodies extensively regulate the production and sale of alcoholic beverages to enforce compliance standards around health, safety, and legal age restrictions. Breweries must obtain permits and licenses from multiple regulatory agencies at both the national and local levels. Strict compliance is essential as non-compliance can result in penalties, fines, facility shutdowns and in the worst cases, incarceration of company executives and owners. The copious regulations also differ across jurisdictions, requiring customization of production, distribution and marketing activities according to local standards. This poses difficulties for equipment manufacturers in designing and producing standardized systems that can operate flexibly according to the diverse regulatory environments. Overall, navigating the complex regulatory landscape surrounding alcohol production requires significant coordination and administrative costs for breweries. Non-compliance remains a legal and reputational risk that brewery equipment companies must help their clients effectively mitigate.

Market Opportunity - New Growth from Compressor Innovations

Innovations in compressor technology, vital in the fermentation and bottling process, are creating new growth opportunities for brewery equipment manufacturers. Advances such as magnetic bearing compressors provide important efficiency gains for breweries. Magnetic bearing compressors consume up to 30% less energy than conventional compressors through their frictionless levitation of the central shaft. This helps reduce operating costs significantly for brewery customers. innovations have also improved the precision, speed and contaminant control delivered by compressors. Faster fermentation and bottling times allow higher volume productivity. Meanwhile tighter contaminant control upholds consistent product quality. To capitalize on demand for these solutions, equipment providers are investing in new facilities and production lines focused on magnetic bearing and other advanced compressor systems. Considering the energy and productivity benefits on offer, breweries are eager to upgrade their operations with the latest compressor technologies. This need is driving robust growth in orders and revenues for innovative brewery equipment manufacturers.