Conveying Equipment Market Trends

Market Driver - Efficient Material Handling for e-Commerce Growth

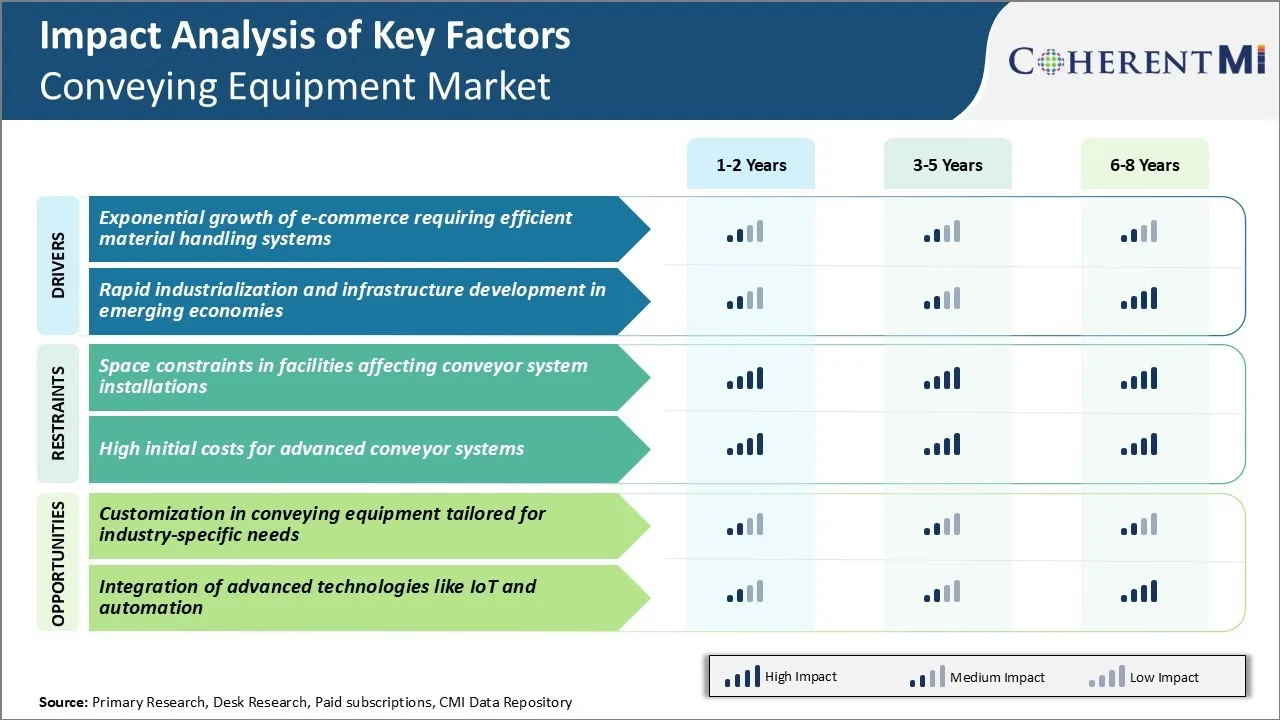

The rapid expansion of e-commerce across the globe has put tremendous pressure on logistics and supply chain networks. Exponential growth in online retail is fueling demand for conveying equipment that can efficiently sort, route, and transport packages and products within facilities.

Modern facilities are leveraging conveying equipment like belt conveyors, roller conveyors, slat conveyors, and floor conveyors along with automated guided vehicles to uniformly distribute workload. This ensures streamlined movement of goods right from receiving docks to sorting stations, inventory shelves, and packing areas.

The rise of online grocery and food delivery in particular is accelerating the requirement for hygienic and responsive conveying equipment. Stainless steel variants able to seamlessly integrate with picking applications are being widely adopted. Moreover, with customer expectations of transparency into order status, manufacturers are embedding sensors and IoT enablement into these machines. This will continue to create new growth avenues for players in the conveying equipment market.

Market Driver - Infrastructural Growth Powers Industrial Automation

Major economies are investing heavily in expanding their industrial and logistic infrastructure to sustain long term economic growth. This creates a highly conducive environment for conveyor system providers in the conveying equipment market.

Industries across segments like automobile, electronics, pharmaceuticals, chemicals, and heavy engineering are automating their plants by incorporating automated guided vehicles and integrated conveyor lines. Industries want to enhance throughput, reduce manual labor requirements and minimize ergonomic risks through mechanized movement of goods and tools within their premises. At the same time, adoption of Industry 4.0 principles is raising the bar for visualization, data connectivity and customizability of these systems.

Overall, the surge in manufacturing capacity additions coupled with worldwide emphasis on supply chain optimization is a core driver propelling the adoption of different product types in the conveying equipment market.

Market Challenge - Space Constraints in Facilities Affecting Conveyor System Installations

One of the major challenges faced by the conveying equipment market is the lack of available space in manufacturing facilities and warehouses for installing conveyor systems. As operations expand and throughput needs to increase, finding space to add more conveyors is becoming a struggle for many companies.

The constrained layout leaves little room for error during installation and commissioning of new conveyor segments. Specialized low-clearance conveyors need to be used in facilities with height restrictions. Space limitations also reduce routing options for conveyors and flexibility in layout design. This can sub-optimally increase travel distances and handling times.

The high costs involved in structural modifications or new construction deter companies from large-scale conveyor system upgrades. This acts as a barrier for the conveying equipment market to capitalize on the growing material handling needs within existing manufacturing footprints. Conveying equipment market players are challenged to innovate compact conveyor designs that maximize throughput within minimal footprints.

Market Opportunity - Customization in Conveying Equipment Tailored for Industry-specific Needs

A major opportunity for the conveying equipment market lies in customizing products to suit the unique material handling requirements of specific industries. No two manufacturing or warehouse processes are identical and a one-size-fits-all approach is rarely optimal.

Semiconductor fabrication requires ultra-clean conveyance in controlled environments. Developing modular, customizable conveyor platforms that can be configured as per industry application opens up new revenue streams. Partnerships with system integrators help roll out ready-to-install, customized conveyor packages for clients across industry verticals. This ensures a perfect fit within the client's existing workflow and optimized performance for their specific material types, throughput needs, and environmental conditions.

It also creates customer lock-in through a seamlessly integrated customized solution rather than off-the-shelf parts. A focus on customization allows the conveying equipment market to expand beyond commoditized standard products and command premium pricing supported by specialized values.