Cylindrical Roller Bearing Market Trends

Market Driver - Rising Demand for High-Speed Applications in Automotive, Aerospace, and Industrial Equipment Sectors

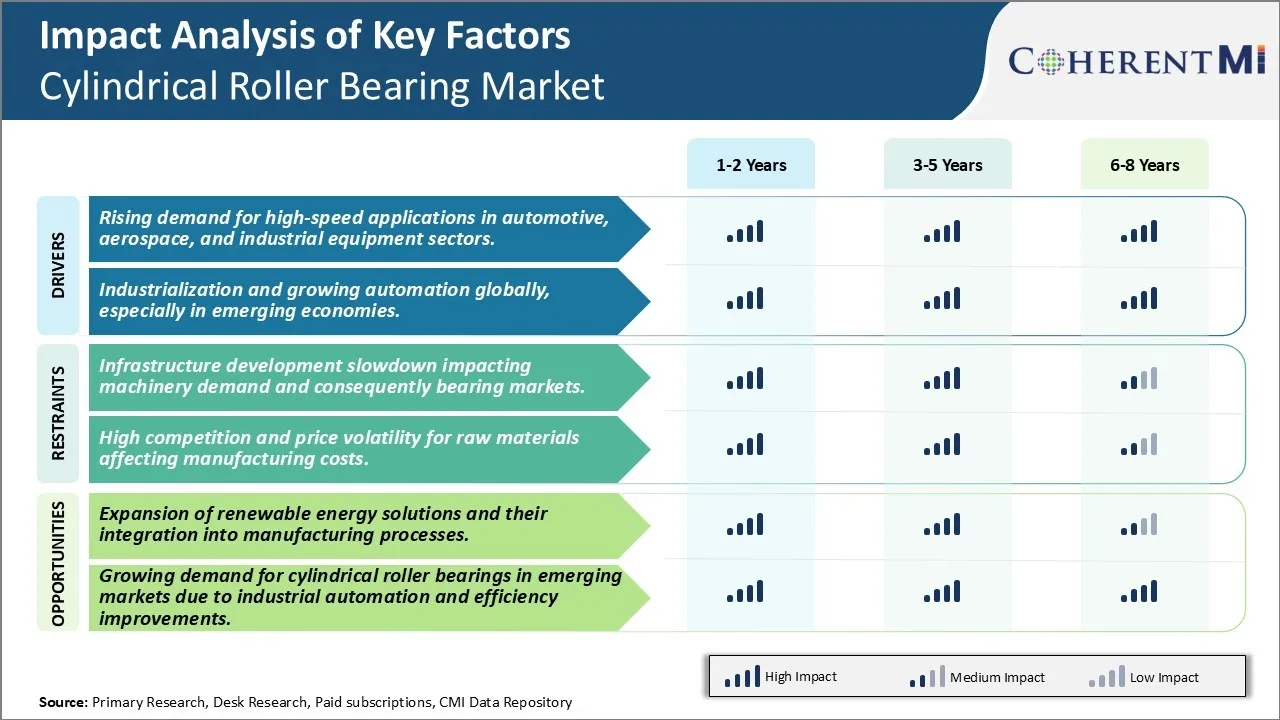

The cylindrical roller bearing market is being positively influenced by the rising demand for bearings that can withstand high rotational speeds and loads from various applications. Cylindrical roller bearings have higher load capacity and can effectively handle radial forces as compared to other bearing types. This makes them highly suitable for numerous high-speed equipment in automotive, aerospace, and industrial machinery.

In the automotive industry, cylindrical roller bearings are extensively used in engine components such as connecting rods, camshafts, steering systems, transmissions, and differentials. With automobile manufacturers focusing more on fuel efficiency and performance, there is a rising demand for lightweight yet powerful engines. This is propelling the development of advanced engine technologies featuring higher compression ratios and revolving parts operating at increased RPMs. Since cylindrical roller bearings can withstand high operating speeds and temperatures generated in modern engines, their adoption is growing steadily. Furthermore, the electrification of vehicles is also augmenting the growth. Heavy-duty bearings are needed in electric vehicle drive motors and gearboxes to handle high rotational speeds.

The aerospace industry is another major end-user utilizing cylindrical roller bearings in various airframe and engine components. As aircraft makers design new aircraft models with advanced engines and systems delivering better fuel efficiency, speed, and reliability, there is greater emphasis on durable bearings.

Industrial machinery ranging from machine tools, pumps, compressors to electric motors also drive the adoption of cylindrical roller bearings. Modern industrial equipment has more precise and compact designs requiring bearings to carry more load without increasing size.

Market Driver - Industrialization and Growing Automation Encourages Industry Growth

Automation has become essential for industries seeking higher productivity and quality through optimized processes. There is growing focus on automation especially in emerging economies which are industrializing rapidly. A key factor facilitating the implementation of automated systems on a wider scale is availability of robust and durable cylindrical roller bearings.

In automated production lines, cylindrical roller bearings are indispensable as they enable various robotic arms, conveyor systems, motors, and machine parts to function seamlessly for prolonged periods without fail. Their versatility in handling both radial and axial loads makes them suitable for a variety of industrial robotic and automation applications. The precision, corrosive-resistance, and load-bearing capacity of cylindrical roller bearings provide uninterrupted machinery operation essential for maximizing line efficiency. Their reliability reduces downtime costs and assists industries in achieving continuous production targets.

As developing nations boost local manufacturing through industrialization programs and incentives, establishment of new automated factories receives major impetus. Industries like automotive, electronics, semiconductor witnessing expansion in emerging markets create simultaneous demand for industrial equipment and cylindrical roller bearings within. Governments promote industrial automation to uplift production capabilities and quality standards at par with global levels. This stimulates installation of advanced, automated production technologies powered by robust bearing components.

Even infrastructure development projects employ heavy machinery automating various tasks. Construction of roads, ports, buildings, and utility networks expands reliance on excavators, cranes, tunnel-boring machines requiring premium cylindrical roller bearings. Their extended lifespan meets stringent performance needs of machinery operating in rugged outdoor conditions. Growing global infrastructure investments thus benefit the cylindrical roller bearing industry.

Market Challenge - Infrastructure Development Slowdown Impacting Machinery Demand and Consequently Bearing Markets

One of the key challenges currently being faced by the cylindrical roller bearing market is the slowdown in infrastructure development activities around the world. Over the past few years, many countries have scaled back their infrastructure spending due to various economic and political reasons. This has negatively impacted the demand for construction and earth-moving machinery which are major consumers of cylindrical roller bearings. The bearing industry is thus witnessing weaker machinery sales, especially for applications in sectors like construction equipment, mining trucks, heavy cranes etc. Furthermore, ongoing global trade conflicts have made many original equipment manufacturers wary about capital expenditures and expansion plans. With reduced orders for their end products, machinery OEMs are also conservative in procuring bearings and other components. The bearing market players need to closely monitor this demand slump from the infrastructure and machinery sectors and adjust their production and capacity expansion plans accordingly to avoid steep corrections.

Market Opportunity: Expansion of Renewable Energy Solutions and Their Integration into Manufacturing Processes

One key area presenting significant opportunities for the cylindrical roller bearing market is the rising adoption of renewable energy resources. With growing emphasis on lowering carbon footprint and transitioning to cleaner fuel sources, many countries are aggressively supporting the growth of solar and wind power generation capacities. This has led to substantial investments and expansion activities in wind turbines and solar panel manufacturing sectors worldwide. As renewable energy technologies are integrated further into industrial processes as well, it is spurring demand for new machinery equipped with advanced bearings. Many original equipment manufacturers are innovating their product portfolio to cater to the special requirements of renewable energy equipment applications. This presents cylindrical roller bearing producers an avenue to penetrate new product segments and customers. By developing bearings specialized for the operational conditions and loads in renewable systems, they can gain opportunities and strengthen their positions in this emerging industry.