Deodorization System Market Trends

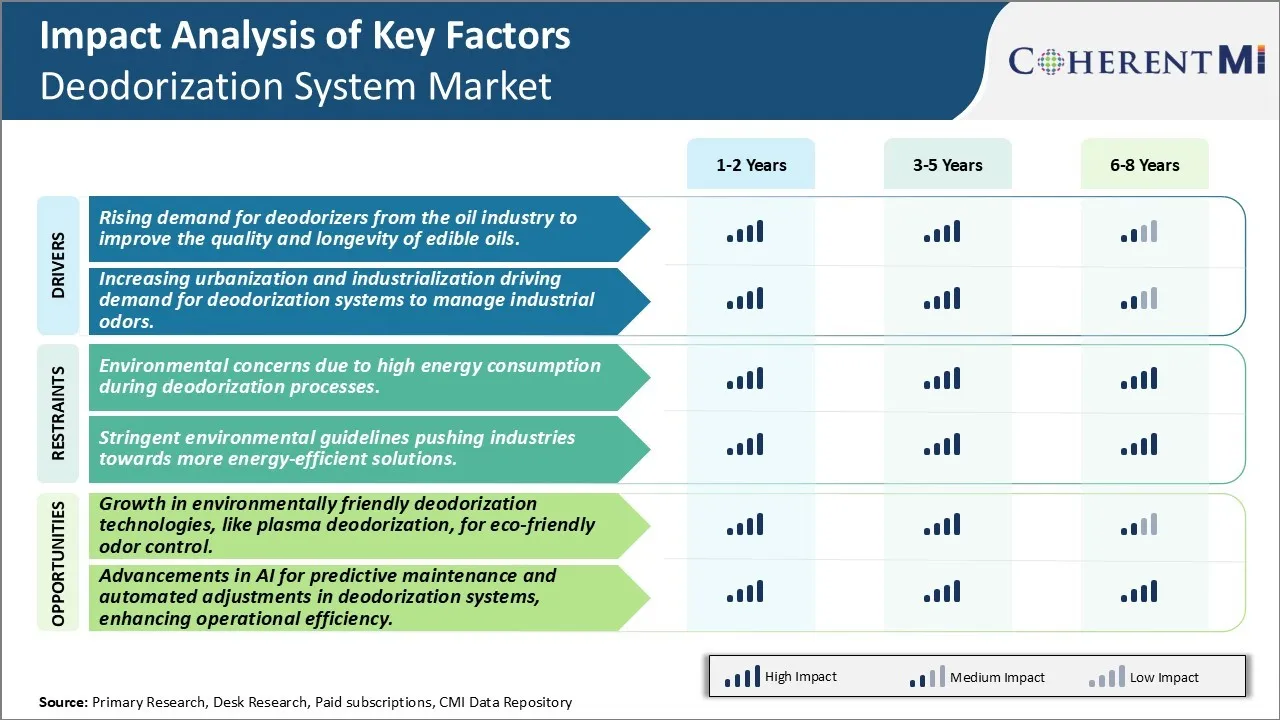

Market Driver - Rising Demand for Deodorizers from the Oil Industry to Improve the Quality and Longevity of Edible Oils

The market is witnessing significant growth on account of rising demand for deodorizers from the oil industry. Deodorization is an important process in the production of edible oils like soybean oil, sunflower oil, palm oil and others. Through the deodorization process, unwanted odors and tastes are removed from the crude oil, thereby improving its quality and making it fit for human consumption.

With rising health awareness, the demand for edible oils is booming globally as they serve as a vital source of nutrients. However, extracting oils from seeds and other sources leaves traces of volatile impurities that impart unpleasant tastes and odors to the oil. If left untreated, these impurities can reduce the shelf life and affect the sensory appeal of the oil. In order to produce edible oils of the highest quality that appeal to consumers, deodorization becomes extremely important.

Modern consumers are more discerning about the purity, taste and smell of the food products they consume. Any presence of off-odors in edible oils can negatively impact their sale. Moreover, stringent food safety regulations around the world mandate that edible oils must be free of contamination and impart perfect sensory characteristics. This has pushed oil producers to invest more in robust deodorization infrastructure to ensure the oils manufactured by them fully comply with standards.

New technologies are also enabling more effective removal of impurities through deodorization. For example, molecular distillation technology can deodorize oils at very low temperatures without destroying heat-sensitive components. Its adoption is growing as it generates oils of superior quality. With rising health-consciousness and quality-oriented demand, edible oil producers are promptly incorporating advanced deodorization machinery to conform to evolving consumer preferences and regulatory norms. This in turn is propelling the Global Deodorization System Market.

Market Driver - Increasing Urbanization and Industrialization Boosts Industry Growth

Rapid urbanization and industrial expansion worldwide have been crucial drivers for the Global Deodorization System Market. As more people migrate to cities for employment and livelihood opportunities, urban centers are burgeoning tremendously. However, large-scale urban and industrial activities also result in greater emission of odorous gases, fumes and smells from various sources such as factories, landfills, sewage treatment, and oil refineries.

If left unaddressed, these odors can cause problems related to the environment and public health. Prolonged exposure to certain smells may lead to respiratory issues, headaches and other ailments. Additionally, foul smells have a negative impact on well-being, reduce work productivity and affect the brand image of towns and cities. As neighborhoods become more densely populated, odor issues assume greater significance. Modern urban residents are also more sensitive towards air quality and demand a living environment free of unpleasant smells.

Against this backdrop, industrial facilities and municipalities are compelled to adopt effective deodorization systems. Technologies such as biofiltration, thermal or catalytic oxidation help capture and neutralize odorous gases at the source itself before they are released. Some plants also utilize scrubbers that use alkaline solutions to dissolve odorous molecules. With urban and industrial development proceeding rapidly across major regions, the need for advanced odor control mechanisms has becoming increasingly indispensable. Governments too are mandating stricter emission standards, boosting investments in sophisticated deodorization solutions.

Market Challenge - Environmental Concerns Due to High Energy Consumption During Deodorization Processes

One of the key challenges currently faced by the deodorization system market is growing environmental concerns due to high energy consumption during traditional deodorization processes. Conventional deodorization techniques like steam distillation require heating oil to very high temperatures of around 200-300°C under vacuum to remove undesirable odor components. This leads to significant usage of fossil fuels and thereby high carbon footprint. It is estimated that deodorization can account for over 15% of total energy usage in vegetable oil refining. With rising climate change awareness, industry stakeholders and regulators are pressing for more sustainable odor removal solutions. Furthermore, strict environmental regulations around the world aim to minimize greenhouse gas emissions from manufacturing facilities. The energy intensive nature of common deodorization methods may discourage their long-term use. Solutions with reduced heat and power requirements need to be adopted to meet sustainability targets and lower environmental impact. Innovation in resource-efficient deodorization technologies is critical for future growth in this industry.

Market Opportunity - Growth in Environmentally Friendly Deodorization Technologies Like Plasma Deodorization for Eco-Friendly Odor Control

The deodorization system market is witnessing increased research and development of green technologies that promise sustainable odor control with lower carbon and energy footprint. One such emerging technology is plasma deodorization which utilizes a non-thermal plasma discharge to selectively destroy malodorous molecules while retaining the chemical and nutritional properties of oils. Plasma systems operate at ambient temperature without the need for vacuum or high heat. They deactivate odor-causing compounds through plasma-induced reactions rather than conventional thermal cracking. Plasma deodorization is commercially viable, cost-effective and ensures up to 80% reduction in energy usage compared to traditional thermal methods. With growing sustainable business practices and eco-label demands, environmentally friendly techniques like plasma will see higher adoption rates among oil processors. Their energy efficient operation and minimal emissions open up new growth avenues. It is estimated that the demand for plasma deodorization units will increase by over 10% annually during the next 5 years.