Diaphragm Pumps Market Trends

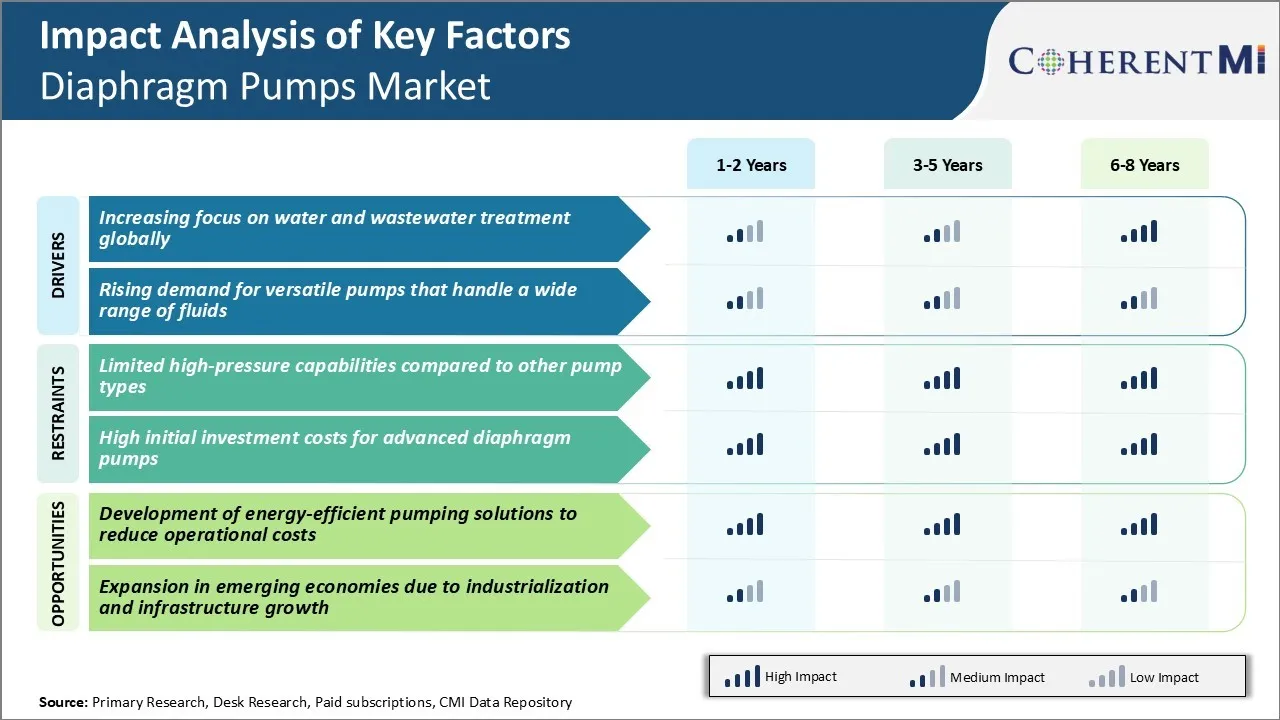

Market Driver - Increasing Focus on Water and Wastewater Treatment Globally

The global demand for clean water has been rising continually along with the growing population. With rapid urbanization as well, the pressure on water resources to meet the needs of municipal, commercial and industrial sectors has increased manifold. Diaphragm pumps are highly versatile and suitable for a variety of applications in water and wastewater treatment processes. Their self-priming feature along with the ability to run dry for short periods enables efficient transportation of liquids through long distances in pipeline networks.

Diaphragm pumps play a critical role in wastewater treatment plants for relocating water from one unit to other during different stages of treatment. Furthermore, water scarcity issues in many parts of the world are driving initiatives for recycling of treated wastewater. This in turn, boosts installations of advanced wastewater treatment infrastructure involving diaphragm pumping solutions. Thereby, this is expected to boost growth of the diaphragm pumps market.

Market Driver - Rising Demand for Versatile Pumps that Handle a Wide Range of Fluids

Diaphragm pumps have seen increasing popularity across various end-use industries owing to their versatility in handling variety of corrosive, abrasive and mixed liquids. Their self-priming function permits them to transfer both thin and viscous liquids efficiently over short or long distance. Whereas the diaphragm, which acts as the sealing component, effectively isolates the fluid being pumped from the pumping mechanism.

Process industries nowadays require pumps that can pump multiple type of fluids involved in a production process without any need for modification in between. Diaphragm pumps fulfill this need of multipurpose pumping with minimum downtime.

Similarly, diaphragm pumps have found increased application in construction sector for transporting cement slurries, grouts and mixed concretes at construction sites. The versatility and robust nature of diaphragm pumps allows them to overcome such tough working conditions efficiently without breaking down. This versatility to handle variety of fluids at varied conditions is acting as a driving factor for diaphragm pumps market.

Market Challenge - Limited High-pressure Capabilities Compared to Other Pump Types

One of the key challenges faced by the diaphragm pumps market is their limited high-pressure capabilities when compared to other types of pumps. While diaphragm pumps are well-suited for low to moderate pressure applications such as transferring oils, solvents and other viscous liquids, they typically can only generate pressures up to 15 bar. This restricts their usage in industries and processes that require higher pressure pumping. Centrifugal pumps, peristaltic pumps and gear pumps are often preferred over diaphragm pumps when higher discharge pressures exceeding 15 bar are necessary. The inability of diaphragm pumps to meet these high-pressure pumping demands acts as a constraint in further market growth. Pump manufacturers need to focus on innovation to enhance the pump design in a way that allows diaphragm pumps to achieve competitive discharge pressures for high-pressure applications as well.

Market Opportunity - Development of Energy-efficient Pumping Solutions to Reduce Operational Costs

The development of energy-efficient pumping solutions represents a major opportunity for the diaphragm pumps market to drive further adoption. Operational cost associated with power consumption forms a significant portion of total pumping costs over the product's life. Thereby, there exists a strong value proposition for manufacturers to develop diaphragm pumps with optimized designs focused on minimal energy usage.

Incorporating features such as advanced motors, variable speed control, and innovative materials could help lower the power ratings and kW requirements of diaphragm pumps. Given their inherent advantages in leak-proof and quiet operation, optimized energy-efficient diaphragm pumps can help reduce the total cost of ownership for end-users. This will enhance the value proposition of diaphragm pumps especially against alternatives and promote increased sales and market expansion opportunities for market players.