Explosion Proof Lighting Market Trends

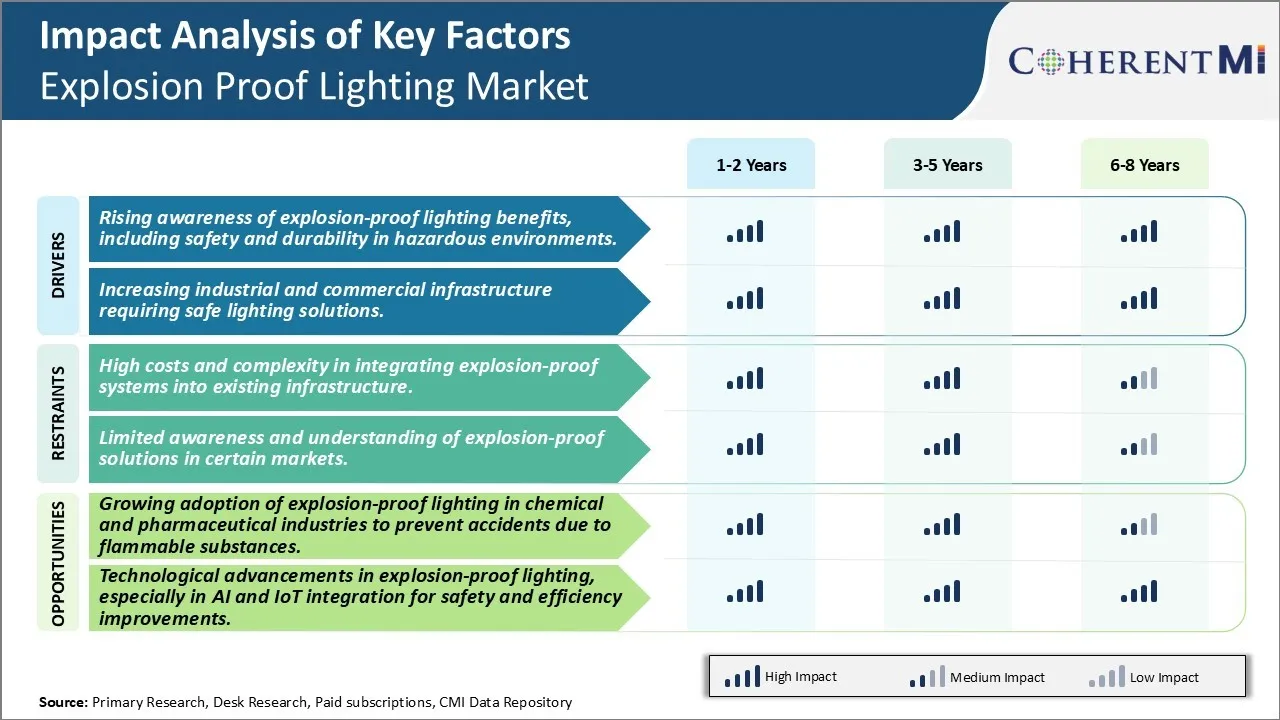

Market Driver - Rising awareness of explosion-proof lighting benefits, including safety and durability in hazardous environments

The use of explosion-proof lighting solutions has become increasingly important in hazardous industrial environments where the risk of explosions due to flammable gases, vapors and dust particles is ever-present. Traditionally, operators in such spaces relied upon incandescent bulbs which carried significant risks of igniting combustible substances. However, with growing awareness about the crucial need for safety in high-risk zones, many facility managers and contractors are now recognizing the key benefits offered by certified explosion-proof LED lighting systems.

These modern explosion-proof fixtures are engineered and tested to stringent international certifications to ensure they cannot cause any sparks or high surface temperatures even in the event of failures or malfunctions. LED bulbs boast a longer operational life as compared to traditional incandescent lamps, thereby reducing maintenance and replacement costs over time. In addition, explosion-proof LED lights consume up to 90% lesser power while providing similar or higher lumen output. This makes them a much more energy efficient choice for industrial applications, offering significant savings on escalating electricity bills.

Importantly, LED explosion-proof lights also emit much less heat compared to other lighting types. This reduces the risk of potentially explosive gases being ignited by an overhead light fixture. Advanced designs with heat sinks and fans help dissipate heat rapidly to maintain safe operating temperatures under all conditions. The shatter-resistant, polycarbonate enclosures of LED lights also make them safer alternatives to glass bulbs commonly seen in hazardous industry zones. Overall, the total cost of ownership over the lifespan is much lower for explosion-proof LED lights vis-a-vis older lighting technologies once maintenance costs are factored in.

With greater awareness about such tangible benefits, many industries such as oil & gas production, chemical and petrochemical plants, mining facilities, grain handling and storage sites among others have been proactively upgrading to certified explosion-proof LED lights. Regulatory bodies are also playing a role by tightening safety norms and inspecting for compliance. This is driving increased spends on high-quality, certified explosion-proof lighting solutions to mitigate risks in hazardous work environments and optimize operational efficiency through energy savings and reduced downtime.

Market Driver- Increasing Industrial and Commercial Infrastructure Requiring Safe Lighting Solutions

Rapid urbanization and industrial growth across major global economies have been driving massive investments into new manufacturing plants, processing facilities, warehouses, transportation and logistics infrastructure over the past decade. Greenfield projects in industries such as chemicals & petrochemicals, energy & power, metals & mining, pharmaceuticals, oil & gas and others often necessitate installation of explosion-proof lighting solutions right from the planning and design stage itself to future-proof operations.

Meanwhile, aging industrial infrastructure is also undergoing large-scale revamps and expansions to boost production capacities and adopt advanced automation & robotics. This presents a big opportunity for replacement of existing lighting with certified explosion-proof LED luminaires in hazardous zones. The evolving regulatory norms around workplace safety in many nations also mandate periodic audits and upgrades to ensure all electrical equipment in hazardous areas conforms to latest internationally accredited certifications. Non-compliance carries the risk of production shutdowns and heavy financial penalties.

Furthermore, the explosion-proof lighting market is seeing increased uptake beyond traditional heavy industry applications as well. Growth sectors such as warehousing and logistics, manufacturing of combustible goods, grain processing facilities and fuel storage depots increasingly recognize the importance of certified safe lighting for their often spacious operational areas. This is expected to open newer revenue streams for explosion-proof luminaire manufacturers in the coming years.

By addressing the illumination needs of rapidly modernizing industrial infrastructure as well as a widening product adoption base, the explosion-proof lighting industry is well-positioned for sustained momentum.

Market Challenge - High Costs and Complexity in Integrating Explosion-Proof Systems into Existing Infrastructure

One of the key challenges faced by the explosion proof lighting market is the high costs and complexity involved in integrating explosion-proof lighting systems into existing infrastructure. Retrofitting existing industrial plants, refineries and chemical facilities with explosion proof lighting requires substantial capital investments since the entire existing wiring and fixtures need to be replaced or upgraded. This leads to prolonged downtime for facilities during the transition which can impact productivity and incur losses. Additionally, explosion proof systems have stringent compliance standards and certification requirements that have to be followed during installation which increases costs. The complexities in ensuring zonal area classification as per industry norms and correctly installing lights that meet those classification standards across vast industrial spaces also contributes to higher installation and maintenance expenses over conventional lighting systems. Facility managers may be hesitant to undertake such upgrades unless critical as return on investments may take longer due to high initial capital outlay.

Market Opportunity: Growing Adoption of Explosion-Proof Lighting in Chemical and Pharmaceutical Industries to Prevent Accidents Due to Flammable Substances

One of the key opportunities for the explosion proof lighting market is the growing adoption of these lighting systems in the chemical and pharmaceutical industries. Workplaces that handle volatile or flammable substances are at high risk of fires and explosions if conventional lighting is used due to the presence of ignition sources. Thus, there is an increased demand for intrinsically safe lighting fixtures that can prevent sparks or abnormal heat generation in areas where combustible fumes or dust may be present. The need to ensure personnel and plant safety has compelled safety managers in these industries to proactively replace existing lights with explosion proof systems. Furthermore, accidents resulting from combustible atmospheres can cause production downtime, legal liabilities and damage brand reputation. Thus, companies are increasingly making capital investments in certified explosion proof lighting as a preventive measure to avoid such risks and maintain continuity of operations. This growing focus on process and personnel safety will continue driving adoption of these specialized lighting systems over the forecast period.