Fiberglass Market Trends

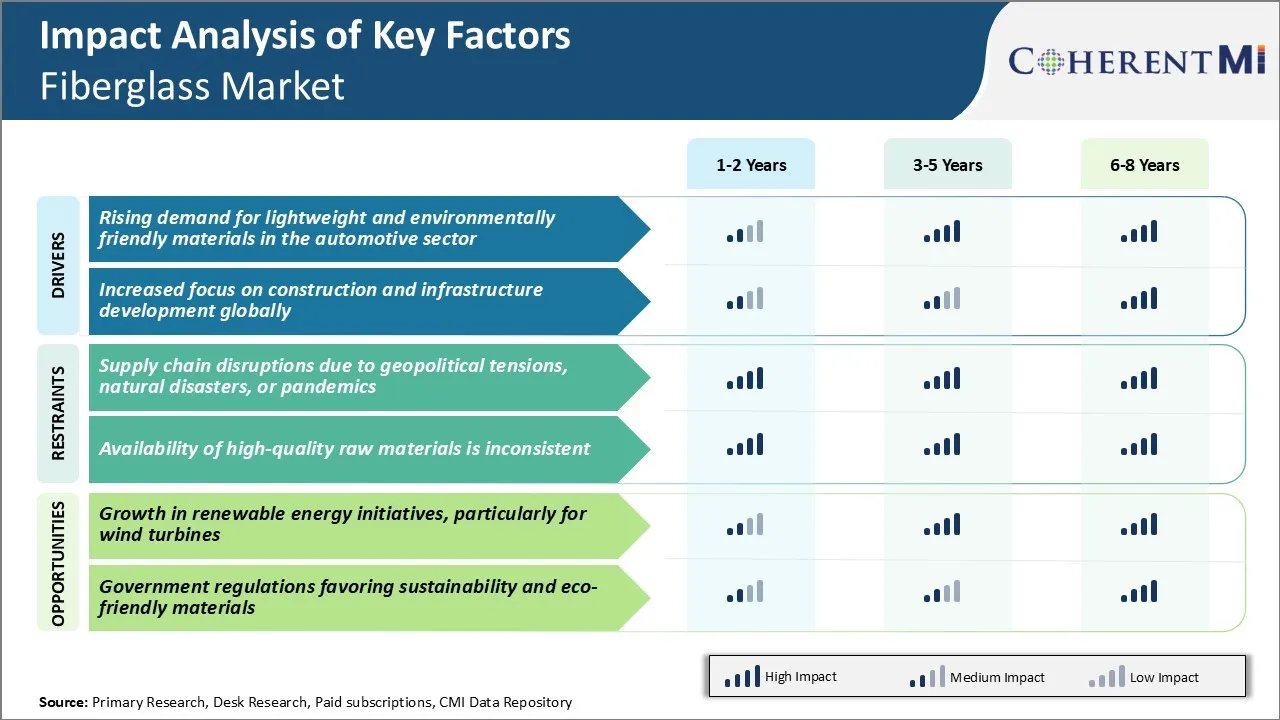

Market Driver - Rising Demand for Lightweight Materials in the Automotive Sector

The automotive sector has been putting increased emphasis on developing lightweight vehicles in order to improve fuel efficiency and reduce emissions. Fiberglass composites are gaining popularity among automakers as they offer substantial weight savings compared to conventional materials like steel. Fiberglass is approximately 30% lighter than steel but provides equivalent strength, due to which players in the fiberglass market are eyeing opportunities in the automotive industry.

Many automakers have started utilizing fiberglass in exterior body panels, roofs, hoods and other non-structural parts to shed kilograms off their vehicles without compromising on performance. Premium manufacturers especially are focusing their efforts on deploying advanced composites to gain an edge in the competitive luxury vehicle segment. Their customers are willing to pay more for vehicles with improved mileage.

Some models have successfully reduced weight by up to 20% through strategic use of fiberglass. This helps them meet stringent fuel efficiency and emission norms without having to downsize engines or make other sacrifices. With regulations getting tighter every year, demand for lightweighting solutions from the auto industry is growing steadily.

Market Driver - Increased Focus on Construction and Infrastructure Development Globally

There is growing recognition among governments worldwide about the critical role that infrastructure plays in long-term economic growth and sustainability. Projects ranging from roads, bridges, rail networks to energy, water and transportation facilities are lining up to be built or modernized.

The construction industry has taken notice of this opportunity and ramped up planning to take on large-scale projects. Fiberglass finds extensive applications in construction from pipes, ducts, panels to architectural structures due to its corrosion resistance, strength, and relatively lighter weight. Its non-conductive properties make it suitable for housing electrical components as well. Fiberglass reinforced plastic (FRP) materials are now commonly used in sanitary applications like bathtubs, sinks etc. where light weight delivers ergonomic benefits.

Developing countries especially in regions like South Asia, Middle East and Africa will see massive investments in building new cities, roads and utilities. Even in developed nations, upgrades to existing infrastructure will open new avenues alongside opportunities from mega project announcements. All factors considered, the global fiberglass market is positioned for sizable gains with increased construction and infrastructure development worldwide forming a structural driver.

Market Challenge - Supply Chain Disruptions due to Geopolitical Tensions, Natural Disasters, or Pandemics

Being a globalized industry, the fiberglass market faces challenges in maintaining an undisrupted supply chain. Geopolitical tensions between major trading nations have disrupted trade routes and availability of raw materials in the past few years. The ongoing Russia-Ukraine conflict is one such example where European nations dependent on Russian natural gas supplies are exploring alternative solutions.

Natural disasters like hurricanes also damage manufacturing and transport infrastructure periodically. The COVID-19 pandemic further highlighted how entire economies can come to a standstill due to public health crises. International border closures and lockdowns stalled movement of goods and people globally. This disrupted Just-In-Time inventory management practices of fiberglass manufacturers.

Sourcing alternative suppliers at short notice to meet production demands is a big challenge in the fiberglass market. Maintaining business continuity and customer satisfaction during such supply chain disturbances requires agile contingency planning and strategizing by market players. Geographical diversification of manufacturing footprints and supplier networks can help mitigate over-dependence on any single region.

Market Opportunity - Growth in Renewable Energy Initiatives

The global transition towards renewable and clean energy solutions presents significant opportunities for the fiberglass market. In particular, the wind energy segment is one of the fastest growing renewable industries. As per industry estimates, annual installations of new wind turbines will need to increase five-fold by 2050 to meet worldwide emissions reduction targets.

Fiberglass features extensively in wind turbine blades for properties like high strength-to-weight ratio, corrosion resistance and longevity under harsh outdoor conditions. As renewable capacity addition gains momentum, the demand for larger wind turbine blades using advanced fiberglass composites will see a proportional rise.

Market leaders are ramping up investments in specialized manufacturing infrastructure to cater to the evolving blade designs. Government subsidies and corporate sourcing commitments are additionally accelerating the adoption of wind power worldwide. The fiberglass market is well-positioned to benefit from this renewable growth momentum in the coming decades.