Food Service Packaging Market Trends

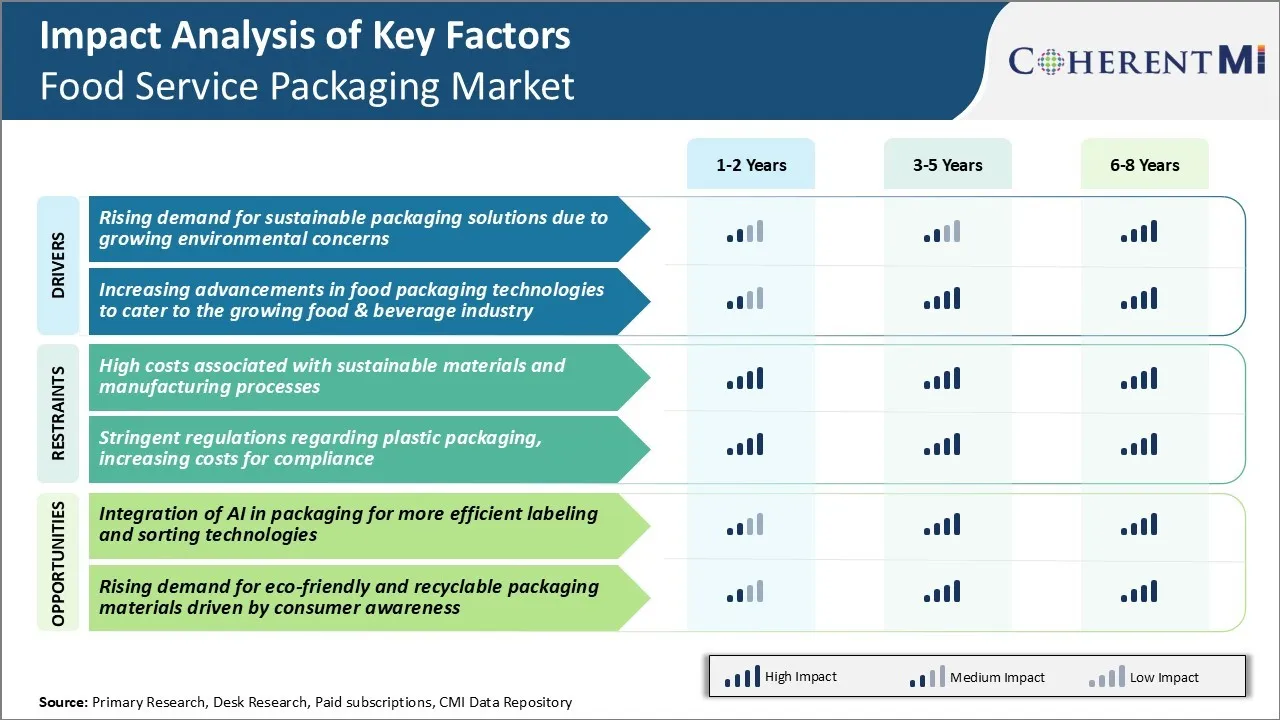

Market Driver - Rising Demand for Sustainable Packaging Solutions due to Growing Environmental Concerns

Environment sustainability has become a major concern globally in recent years. There is increasing awareness about reducing, reusing and recycling of plastic packaging materials. This has prompted food service packaging manufacturers to invest more in developing sustainable packaging solutions made from eco-friendly materials.

Many quick service restaurants and food brands are announcing goals to use packaging made from recyclable or compostable materials. Some brands have even started testing reusable containers and encourage consumers to return them after use. Compostable food service packaging made from renewable plant-based materials like bagasse, bamboo, and corn starch are finding more acceptance.

Government regulations banning certain single-use plastic items have accelerated the urgency for the industry to switch to alternative food service packaging types. Packaging manufacturers have ramped up their R&D efforts to engineer innovative designs utilizing recycled content plastic, paper, and bio-plastics. Close collaboration across the value chain from brand owners to retailers will be key to optimize transition in the food service packaging market.

Market Driver - Increasing Advancements in Food Packaging Technologies to Cater to Food & Beverage Industry

The food and beverage industry has been experiencing steady growth globally, led by changing consumer demands, growing disposable incomes, and on-the-go lifestyles. Advancements in active and intelligent food service packaging technologies have enabled real-time monitoring of food quality parameters like moisture, gases, pathogens, etc.

Such smart packaging integrated with sensors, RFID tags, and interactive displays are gaining popularity among quick service brands. Digital printing coupled with functional inks allows for customized graphics, variable information, and traceability codes on packages, driving a new trend in the food service packaging market.

New formats like flexible pouches, skin packages, and fanny packs endorsed by leading brands have boosted availability of portion-controlled ready-to-consume snacks and meals. Popularity of healthy cuisine segments like fruits, salads, sandwiches and juices is driving demand for aseptic cartons, bottles, and stand-up pouches. 3D printing and robotics applications are increasingly redefining shapes, sizes, and forming procedures of food service packaging products.

Market Challenge - High Costs Associated with Sustainable Materials and Manufacturing Processes

One of the major challenges faced by the food service packaging market is the high costs involved in adopting more sustainable materials and manufacturing processes. Transitioning to renewable and recyclable substrates requires significant investment in R&D to develop new packaging formats.

Additional considerations like the need for specialized machinery, different production workflows, separate waste handling also increase the per-unit manufacturing costs. The lack of economies of scale in the early stages of commercializing new sustainable packages further compounds these cost disadvantages. Passing on the full incremental costs to customers also risks losing price-sensitive customers to competitors in the food service packaging market providing conventional packages at lower price points.

Overall, the current cost differentials pose major adoption barriers for industry players and slow down the transition towards a circular economy for food service packaging. Addressing these economic challenges is critical in the food service packaging market to accelerate the large-scale development and deployment of truly sustainable alternatives.

Market Opportunity - Integration of AI in Packaging for More Efficient Labeling and Sorting Technologies

Integration of artificial intelligence (AI) and machine learning technologies present opportunities to make food service packaging smarter and more efficient. AI-based labeling solutions can automate the production process, reduce errors and drive significant cost savings compared to manual labeling.

AI is also improving sorting and segregation of used food packaging at recycling facilities. Optical character recognition and defect detection models using computer vision algorithms can rapidly and accurately sort different types of recyclable materials like plastics, papers, metals at high speeds with minimal human intervention.

This level of precision and automation boosts recovery rates and improves the quality of sorted streams for later reprocessing. Overall, AI is making packaging and recovery systems smarter, more data-driven and efficient which can help advance sustainability efforts across the food service value chain in the food service packaging market.