Freight Railcar Parts Market Trends

- Adoption of Predictive Maintenance: The adoption of predictive maintenance is an emerging trend in the rail industry. This involves using technologies like IoT sensors, AI, machine learning, and big data analytics to monitor railcar components in real-time. It enables prediction of possible failures and proactive maintenance. Predictive maintenance for railcars minimizes unplanned downtime. It optimizes maintenance schedules, improves safety and extends service life of components. This reduces costs associated with replacements and repairs. As rail operators increasingly adopt predictive maintenance, the demand for advanced IoT enabled railcar parts is expected to rise.

- Incorporation of Lightweight Materials: Manufacturers are increasingly using lightweight composite and alloy materials in production of railcar parts. Replacement of steel components with lightweight materials such as titanium, aluminum, and reinforced plastics can reduce overall weight of railcars. This enhances energy-efficiency, increases cargo capacity and improves running speeds. Lightweighting also facilitates noise reduction and low maintenance. Companies are focused on R&D to develop durable lightweight components including bogies, couplers, doors, brake systems, etc. The lightweighting trend is expected to rise further with focus on efficiency.

- 3D Printing for Prototyping and Production: 3D printing technology is being rapidly adopted in the rail industry for prototyping as well as manufacturing of components. 3D printing enables flexible, cost-effective, and low waste production compared to traditional methods. Parts with complex geometries can be easily 3D printed. Railcar manufacturers use 3D printing to create prototypes for testing. The usage of 3D printing for direct production of small volume parts and custom components is also rising. As the technology matures further, 3D printing is expected to be used for mass production of railcar parts.

- Increasing Use of IoT Connected Parts: The IoT connected railcar parts are experiencing increasing adoption due to benefits such as real-time condition monitoring, predictive maintenance, geotracking and improved fleet analytics. IoT connectivity in components such as doors, brake controllers, temperature sensors, helps monitor their performance and usage data. Rail operators are increasingly demanding IoT connectivity in railcar parts for gaining insights into assets. IoT enables gathering vital data to optimize railcar maintenance and safety. The integration of IoT in railcar parts is expected to rise with focus on connected vehicles.

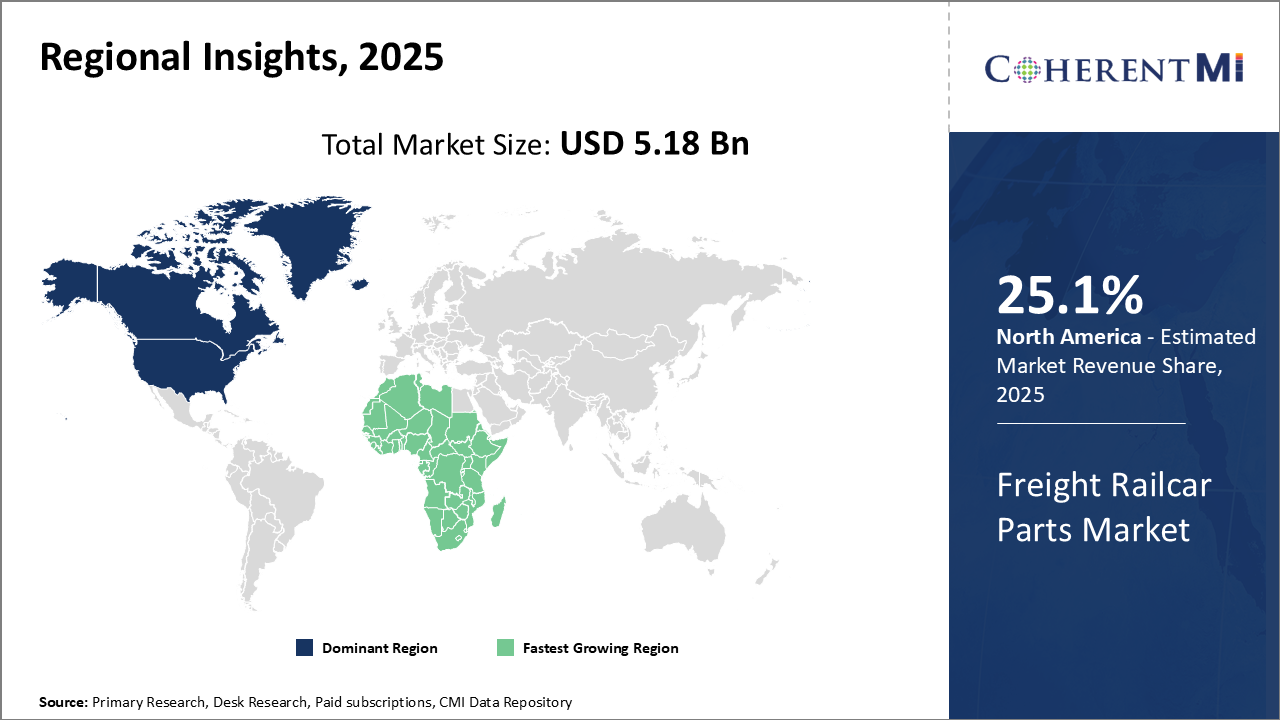

Freight Railcar Parts Market Regional Insights

- North America is expected to be the largest market for Freight Railcar Parts Market during the forecast period, accounting for over 25.1% of the market share in 2025. The growth of the market in North America is attributed to the well-established railroad infrastructure and large fleet of freight railcars in the region.

- The Asia Pacific market is expected to be the second-largest market for Freight Railcar Parts Market, accounting for over 35.2% of the market share in 2025. The growth of the market in is attributed to the rapidly expanding railway sector and government initiatives to improve freight transportation in emerging Asian countries.

- The Middle East & Africa market is expected to be the fastest-growing market for Freight Railcar Parts Market, with a CAGR of over 5.2% during the forecast period. The growth of the market in Middle East & Africa is attributed to the development of new railway lines and increasing demand for freight transportation due to rapid urbanization in the region.