Gas Turbine Air Filter Market SIZE AND SHARE ANALYSIS - GROWTH TRENDS AND FORECASTS (2024 - 2031)

Gas Turbine Air Filter Market is segmented By Product (Inlet Air Filters, Cartridge Filters, HEPA Fi...

Gas Turbine Air Filter Market Trends

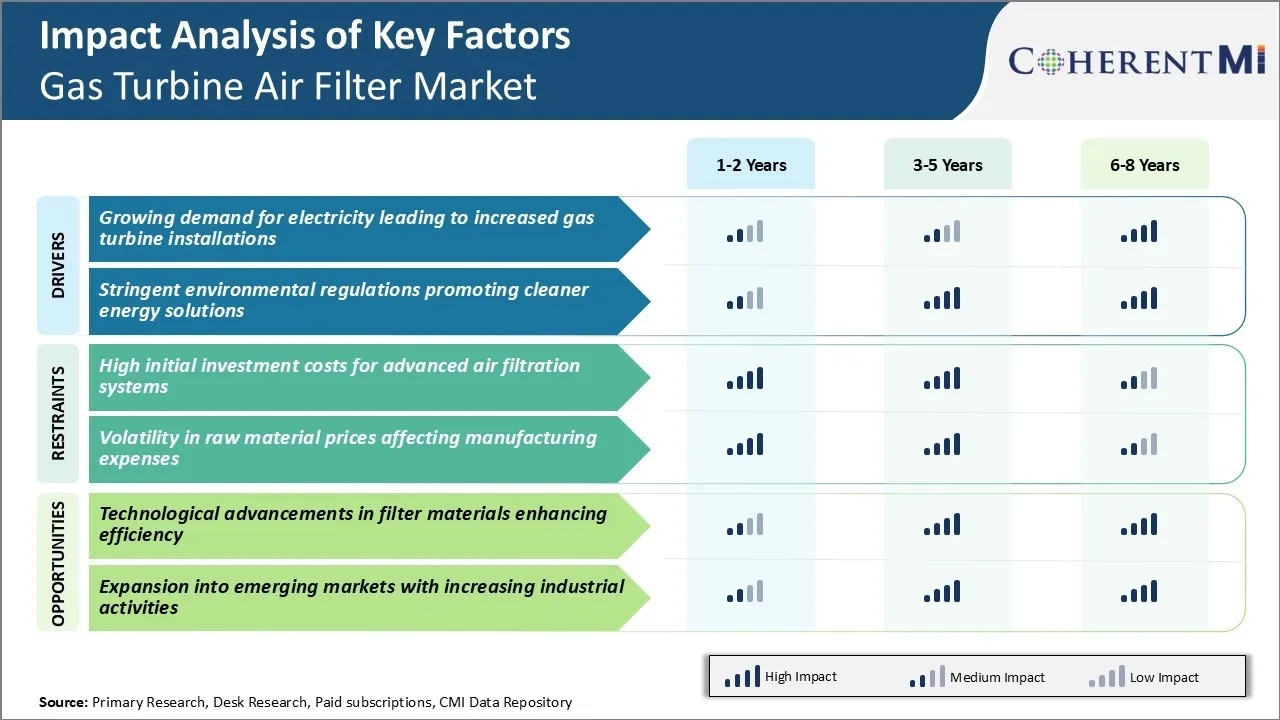

Market Driver - Growing Demand for Electricity Leading to Increased Gas Turbine Installations

Growing demand for electricity across both developed and developing nations has been one of the key drivers for the increased adoption of gas turbines for power generation in the past decade. Gas turbines have emerged as one of the preferred alternatives for utilities and independent power producers to add new generation capacities in a relatively short timeframe.

Many countries in Asia Pacific and Middle East regions are witnessing high economic growth which has translation into rapidly rising demand for reliable power supply. This has led to large investments into new gas turbine-based power projects to bridge the demand-supply gap. Even in developed regions of North America and Europe, gas turbines are helping utilities to meet peal power needs and also aid integration of renewables by providing fast-ramping balancing capabilities.

Electricity demand is set to rise further in coming years across both developing and developed regions. So, new gas turbine installations are expected to continue at strong pace providing opportunities for companies in the gas turbine air filter market.

Market Driver - Stringent Environmental Regulations Promoting Cleaner Energy Solutions

Environmental regulations around the world have been getting more and more stringent over the past decade as climate change risks became more apparent. At the same time, there is a growing preference amongst policymakers and public to switch towards cleaner sources of energy to achieve long term sustainability targets.

Many gas turbine models available today also have capabilities to fire low-carbon fuels like hydrogen either in a blended form or as a single fuel. Leading OEMs are further optimizing the combustion systems of gas turbines to minimize NOx and other regulated emissions without compromising on efficiency. The ability to demonstrate lower carbon and green credentials through emissions compliances has provided an edge to gas turbines over alternatives while seeking approvals and incentives under support schemes.

Overall, the tightening environmental regulatory landscape is promoting greater adoption of clean and efficient technologies like modern gas turbines for utilities and industrials. This is expected to drive growth of the gas turbine air filter market.

Market Challenge - High Initial Investment Costs for Advanced Air Filtration Systems

One of the key challenges faced by the gas turbine air filter market is the high initial investment costs associated with advanced air filtration systems. Implementing high-efficiency particulate air (HEPA) or ultra-low particulate air (ULPA) filter technologies for industrial gas turbines requires significant capital expenditure. This is a barrier for end-users, especially in developing markets where budgets are constrained. The advanced filter media and housing needed to achieve stringent filter classes like e12, f7 or h14 per ISO can increase total project costs substantially.

Additionally, regular filter replacement drives long-term operational expenditures higher compared to conventional methods. The payback period for such investments may extend beyond 18-24 months in some application areas. However, with growing environmental regulations and performance requirements, advanced air filtration will need to become more cost-competitive to see wider acceptance across all regions and industry verticals.

Market Opportunity - Technological Advancements in Filter Materials Enhancing Efficiency

One of the key opportunities for the gas turbine air filter market lies in ongoing technological advancements in filter materials. Continuous research and development are enhancing the efficiency and lifespan of filtration media, helping to reduce overall costs.

Additive manufacturing is also enabling complex three-dimensional lattice structures for filters with optimized flow characteristics. There is also progress in surface modification techniques that help repel dirt and extend cleaning cycles.

Such innovations are improving the price to performance ratios of advanced solutions. This makes premium filtration options more accessible and appeals to a broader set of end-use applications. Going forward, further material engineering can boost filtration efficiencies and help accelerate payback periods for capital expenditures on high-end gas turbine air filter systems.