Industrial Vehicle Market Trends

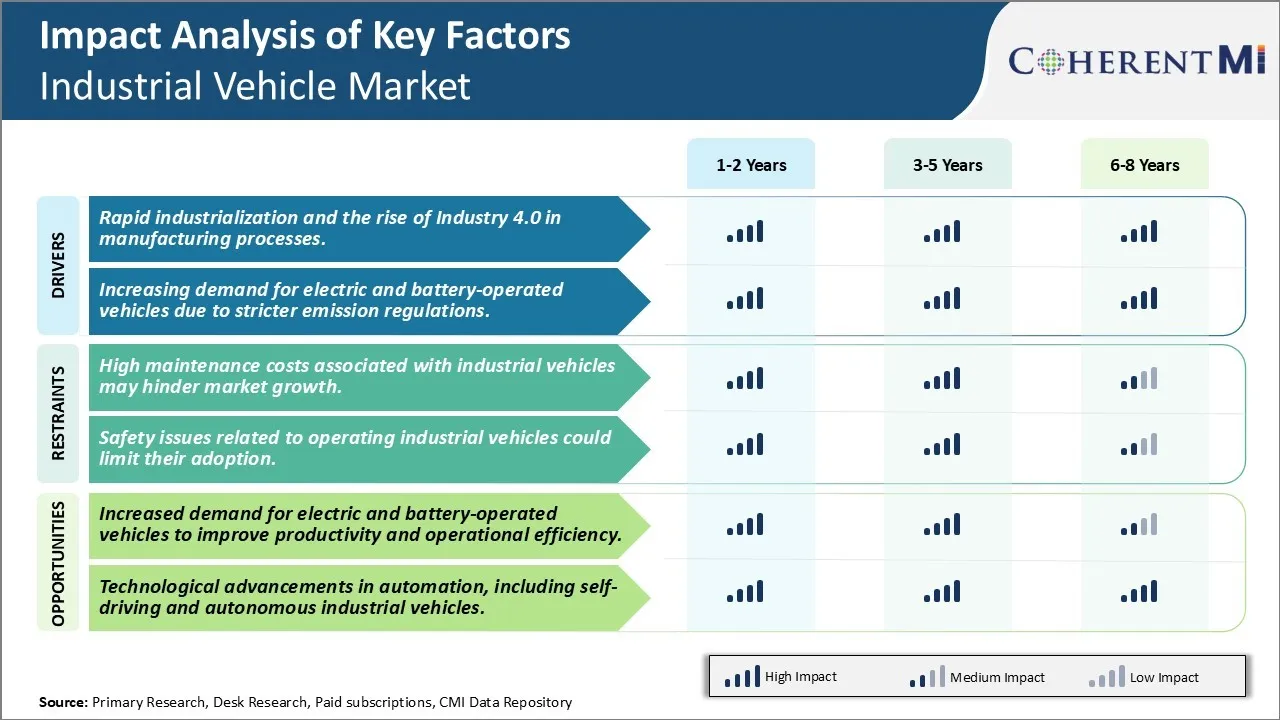

Market Driver - Rapid Industrialization and the Rise of Industry 4.0 in Manufacturing Processes

With rapid industrialization taking place across major developing regions such as Asia pacific and Latin America, the manufacturing sector is going through a transition. Counties are focusing on enhancing productivity and efficiency in production processes through advanced technologies such as robotics, IoT, big data analytics and cloud computing. This transition broadly known as Industry 4.0 is increasingly getting adopted by leading manufacturers globally.

The core principle of Industry 4.0 involves connecting industrial production facilities and integrating them with existing information systems. This allows real-time data collection from machines and equipment on plant floors which helps in remote monitoring and predictive maintenance. It brings data driven intelligence right on the production line for improved decision making. Manufacturers are now able to gain deeper insights into their operations and optimize processes accordingly.

One of the major outcomes of Industry 4.0 initiative has been increased automation through deployment of robotic solutions. Advanced robotics equipment is replacing human workforce for handling complex and repetitive tasks. This is helping manufacturers cope up with challenges like labor shortage and enhance productivity multi-fold. However, with high installation of robots comes the demand for supporting vehicles that can safely and efficiently work around these automated machines.

Overall, rapid industrialization and ongoing Industry 4.0 revolution is propelling the production volumes across manufacturing hubs globally. At the same time, demand for intelligent logistics solution is increasing to support highly automated plants of future. This emerging transformation clearly plays into the growth of industrial vehicle market that caters to evolving material & inventory movement needs of smart factories. Their sustained deployment will be pivotal for factories to maximize Industry 4.0 benefits and reap fruits of digital transformation.

Market Driver - Increasing Demand for Electric and Battery-Operated Vehicles Due to Stricter Emission Regulations

With rising environmental awareness, many countries have implemented stringent emission norms for industrial and commercial vehicles. Regulatory bodies are particularly focusing on curbing toxic emissions from fuel-based vehicles used within indoor production facilities, warehouses and logistic parks. This is mainly because exhaust from internal combustion engines contains harmful gases like carbon monoxide, nitrous oxides, particulate matter etc. Continuous exposure to such emissions pose serious health risks.

In view of tightening emission regulations, industrial vehicle manufacturers are developing more environment-friendly alternatives. All electric and hybrid-electric vehicles are seen as viable replacements to traditionally used diesel or gasoline vehicles. By replacing the fuel engine with an electric motor, they ensure zero-tailpipe emissions within closed spaces. Their silent operation is also preferred over noise generating internal combustion engines.

Battery technologies are advancing rapidly, helping electric vehicles achieve longer driving ranges on single charge. Advanced Lithium-ion batteries utilized in new generation electric trucks and forklifts provide powerful performance comparable to gasoline counterparts. Furthermore, compatibility with fast charging infrastructure addresses issues of limited driving range associated with older battery versions. This improves the practical usability of electric vehicles for real-world industrial applications.

Rising environmental sensibilities among manufacturers make them inclined towards green fleet upgradation programs. Electric vehicles enable reducing carbon footprint as well as lowering operating costs through savings on fuel and maintenance in long run. With growing availability of subsidies and incentives for electric commercial vehicles, their adoption is accelerating further. The preference for battery-powered industrial transport augurs well for electric vehicle industry and positively impacts relevant markets growth. Strict laws compelling compliance with emission norms will continue directing this technology shift in near future.

Market Challenge - High Maintenance Costs Associated with Industrial Vehicles May Hinder Market Growth

The industrial vehicle market faces significant challenges due to the high maintenance costs associated with these specialized equipment. Industrial vehicles such as forklifts, tractors, loaders etc. involve complex machinery and components that require frequent servicing and repairs to ensure operational efficiency. This makes maintenance one of the largest cost components for owners of industrial fleets. Factors such as wear and tear of parts due to continuous usage in tough working conditions, repair or replacement of damaged components and the use of specialized skills for maintenance work drives up the total cost of ownership considerably. According to the analysis, maintenance costs can account for over 20% of the total lifetime expenditure on an industrial vehicle. With economic slowdown in many regions globally, companies are looking to optimize costs wherever possible. The high sunk costs associated with maintenance can act as a deterrent for fleet expansion plans. Manufacturers will need to focus on building vehicles with enhanced durability and reliability so the frequency of repairs is reduced. Also servicing networks need to offer cost effective maintenance packages to help lower the costs borne by customers. Unless these issues are addressed, rising maintenance bills can negatively impact future demand for industrial vehicles.

Market Opportunity - Increased Demand for Electric and Battery-Operated Vehicles to Improve Productivity and Operational Efficiency

There is a growing market opportunity for electric and battery-powered industrial vehicles. Driven by factors such as rising energy costs, stringent emission norms as well as productivity and efficiency considerations, many companies are actively exploring electric vehicles for their warehousing and logistics operations. Electric industrial vehicles have distinct advantages - they are more environment friendly as they do not emit pollutants. They are also more energy efficient since the electricity required to power them is cheaper than diesel in the long run. Most importantly, electric vehicles improve workforce productivity. Their quieter operations allow intensive use in multiple shifts without noise restrictions. Automatic functions replace manual levers, enabling easier and faster operation. Fleet managers are able to closely monitor battery status and charging requirements remotely. Overall, electric vehicles have up to 20% higher productivity over diesel or gas variants. Their improved efficiency positively impacts transportation and labor costs. With continuous technology advances, the performance limitations of early electric vehicles are disappearing. If manufacturers can address range anxiety issues and bring down battery prices further, the industrial electric vehicle market is poised for exponential growth in the coming years.