Insulated Packaging Market Trends

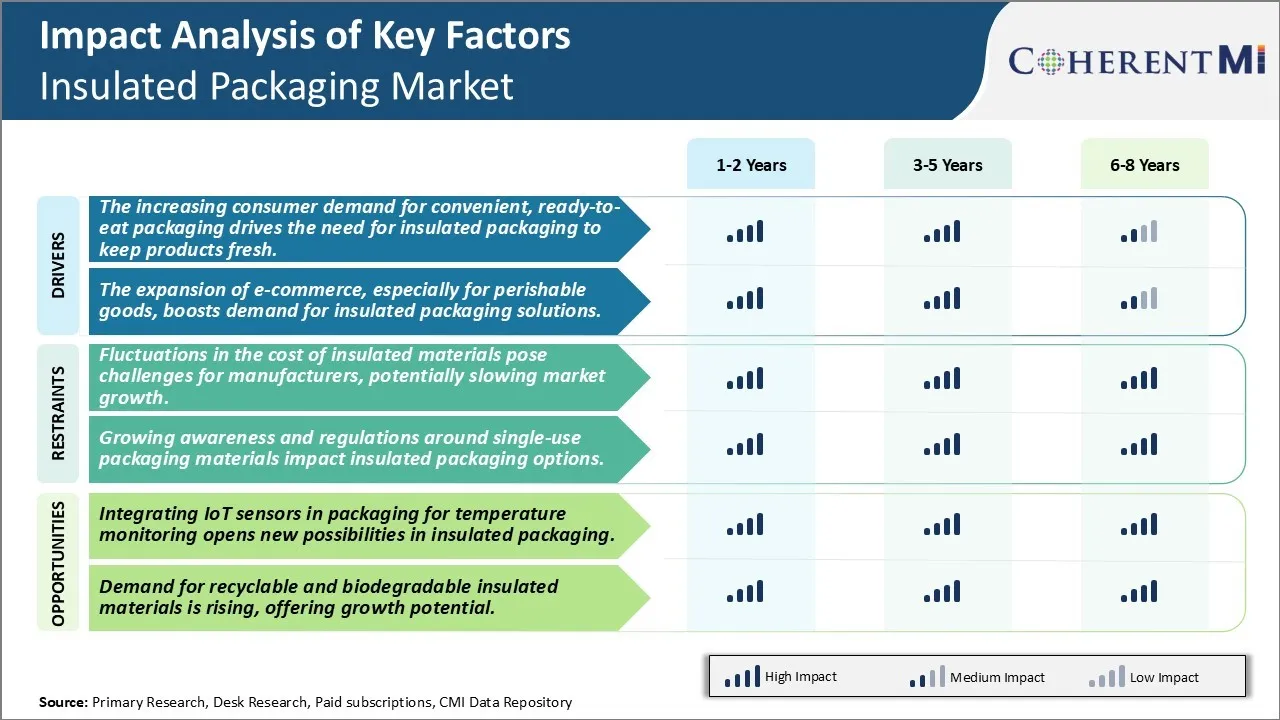

Market Driver - The Increasing Consumer Demand for Convenient, Ready-To-Eat Packaging Drives the Need for Insulated Packaging to Keep Products Fresh

With increasingly hectic lifestyles, consumers are constantly looking for convenient packaging solutions that can be easily accessed and consumed on-the-go. There has been a notable rise in demand for ready-to-eat and prepared meals over the past decade owing to the lack of time for food preparation at home. As customers seek maximum convenience, packaged food products that provide portion-controlled servings and require minimal or no preparation have gained immense popularity. However, prepared foods are highly perishable in nature and require proper temperature-controlled packaging to maintain freshness and edibility. This has spurred the need for insulated packaging materials and solutions that can withstand fluctuations in temperature while transporting and storing ready-to-eat goods.

Insulated packaging plays a critical role in extending the shelf-life of perishables and allowing food to retain its nutritional value, taste and appeal over long periods. It prevents deterioration by minimizing moisture gain or loss and protecting the contents from external heat, cold or freezing temperatures. A variety of insulation options including expanded polystyrene, extruded polystyrene, urethane and fiberglass are being incorporated into packages for chilled, frozen or temperature-sensitive products. Advanced insulation technologies are enabling packages to withstand temperatures ranging from -40°C to 121°C for over 24 hours or more. With optimum insulation, suppliers can now deliver prepared foods across long distances while meeting stringent quality and freshness standards.

Moreover, as lifestyles become more mobile, there is rising demand for portable snack packs and smaller on-the-go meal kits that can be easily carried and consumed anywhere. Insulated packaging formats like coolers, sleeves and containers allow the distribution of pre-portioned, fresh mini-meals for travelers, commuters and outdoor enthusiasts. Their ability to maintain an optimal internal temperature for over 8-12 hours without refrigeration expands the scope for convenient consumption even outside of typical mealtimes. The growth in demand for ready meals and snacks thus propels the insulated packaging industry to innovate compact, high-performance solutions for situational eating.

Market Driver - The Expansion of E-Commerce, Especially for Perishable Goods, Boosts Demand for Insulated Packaging Solutions

The dramatic growth of online shopping over the past decade has significantly impacted packaging demands, especially for perishables. With the rise of quick commerce and same-day delivery models, e-commerce provides customers ease and immediacy in purchasing produce, bakery items, meat, seafood and frozen goods straight from their mobile devices. However, efficient temperature monitoring and insulation becomes critical to preserve freshness during the door-to-door deliveries that sometimes span several hours. With customers increasingly intolerant of damaged or spoiled products, e-tailers need robust protective solutions to withstand the demands of the online supply chain.

Specialized insulated mailers, cartons and boxes have thus become indispensable for long-distance refrigerated transport of perishables via e-commerce. Advanced designs with insulation layers, cushioning and temperature tracking capabilities protect shipments from environmental conditions while providing transparency. Several platforms also offer temperature-controlled packaging, often paired with reusable ice packs, gel packs or chemical activated coolants to maintain a cool interior environment through multiple deliveries per day. Such innovations boost consumer confidence in purchasing fresh items online by minimizing risks of degradation during deliveries.

At the same time, direct-to-consumer brands are increasingly relying on e-commerce to reach niche audience segments. Smaller manufacturers of specialty foods, organic produce as well as dietary-restricted offerings require insulation to safely transport highly perishable products over long distances. They turn to customized solutions from packaging vendors that offer branding opportunities alongside reliable thermal protection tailored to unique specifications. As future-focused consumers continue embracing the convenience of online grocery platforms, there will

Market Challenge - Fluctuations in The Cost of Insulated Materials Pose Challenges for Manufacturers, Potentially Slowing Market Growth

Fluctuations in the cost of insulated materials pose challenges for manufacturers, potentially slowing market growth. The cost of key raw materials used in the production of insulated packaging solutions such as plastic resins, paper, and foam insulators tends to fluctuate frequently based on global commodity price shifts. Any increases in the prices of these raw materials directly impacts the production costs for manufacturers. With thin profit margins in the insulated packaging industry, manufacturers often find it difficult to absorb these additional costs without passing them on to customers in the form of price hikes. This renders their solutions less price competitive compared to alternatives. There is also the challenge of demand uncertainty from customers during periods of high material costs. With customers choosing to reduce order quantities or delay procurement, manufacturers may have to scale down production. This in turn affects their capacity utilization and overall profitability. Frequent cost fluctuations thus present capacity planning and pricing challenges for insulated packaging manufacturers. It also restricts their ability to undertake strategic long-term investments needed to drive innovation and market expansion. If left unaddressed, these issues could stall the growth momentum of the insulated packaging industry.

Market Opportunity- Emergence of IoT Sensors in Packaging Industry to Create New Avenues

Integrating IoT sensors in packaging for temperature monitoring opens new possibilities in insulated packaging. By embedding sensors that can track temperature conditions during transit both internally and on the exterior packaging surface, critical information on temperature compliance can be gathered. IoT connectivity built into the packaging then enables this data to be transmitted in real-time to all relevant stakeholders. This allows shippers and end customers to proactively monitor shipments and ensure product safety and quality are maintained according to regulatory and industry standards. It also eliminates the need for resource-intensive manual temperature data logging during transportation. Manufacturers can leverage such smart active packaging solutions to unlock valuable use cases across industries including healthcare, pharmaceuticals, food and beverage. This translates to immense market potential and better margins driven by value additions. By offering transparency and accountability, IoT-enabled insulated packaging assists in building long term customer loyalty and trust as well. This emerging technology presents a pivotal opportunity for innovators to gain first-mover advantage and accelerating revenue growth in the coming years.