Paperboard Packaging Market Trends

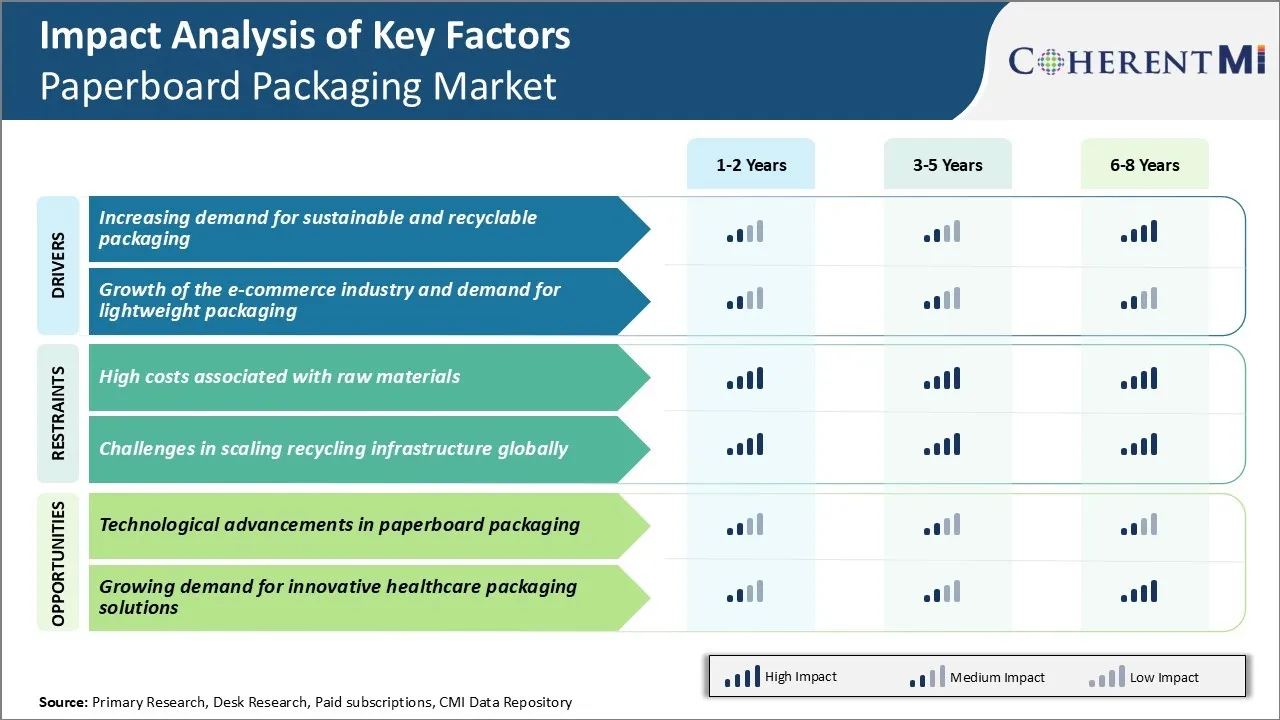

Market Driver - Rise of Sustainable and Recyclable Packaging

One of the major drivers fueling growth in the paperboard packaging market in the coming years is the increasing demand for sustainable and eco-friendly packaging materials. Paperboard is widely considered to be one of the most sustainable packaging choices as it comes from a renewable resource and is easily recyclable. Additionally, more and more brands are emphasizing their use of paperboard for packaging as consumers are willing to pay premium prices for products with sustainable packaging.

Governments and regulatory bodies across nations are encouraging the shift to sustainable materials through policies and directives. Manufacturers are hence compelled to develop packaging made from recyclable fibers like paperboard to adhere to these mandates.

With the world facing worsening environmental damages due to plastic waste, there is mounting pressure on industries to reduce reliance on single-use plastics and switch to sustainable alternatives like paperboard. Both regulatory pushes as well as consumer demand for eco-friendly options are steering the packaging sector towards recyclable materials like paperboard. This is fueling higher growth for paperboard packaging.

Market Driver - Booming E-Commerce and Demand for Lightweight Packaging

The exponentially rising prominence of online shopping and e-commerce is having a momentous effect on the packaging sector globally. More and more products are being sold through websites and apps instead of brick-and-mortar stores which requires protective, affordable, and lightweight packaging to maintain quality during shipping.

Paperboard fulfills the need for convenience and efficiency in packaging admirably as it offers durability for protecting products during deliveries. It is also more lightweight compared to materials like glass or plastic. This aids in keeping packaging costs low for shipping items long distances through carriers. Its compressibility allows easy storage and transport of stacks of folded boxes among many other efficiency advantages.

With global e-commerce projected to continue its stratospheric growth over the next decade, packaging suitable for the unique requirements of online retail will be crucial. Here paperboard is expected to be a key beneficiary given its ideal characteristics for lightweight and affordable protection of goods during shipments. This will sustain high demand and ensure ongoing growth opportunities for paperboard packaging market players in the booming e-commerce sector.

Market Challenge - High Costs Associated with Raw Materials

One of the key challenges faced by the paperboard packaging market is the high costs associated with raw materials. Paperboard is primarily made from wood pulp which comes from trees. The process of extracting wood pulp from trees and processing it into paperboard is a multi-step process that requires a significant number of raw materials and energy. The costs of procuring wood, processing it into pulp, and then manufacturing the pulp into paperboard continue to rise due to increasing global demand and supply chain constraints.

Additionally, fluctuations in commodity prices also affect the costs of wood pulp. With raw material costs accounting for a major part of the overall production costs, any increase in these costs puts pressure on the margins of paperboard packaging manufacturers. The rising raw material prices challenge the ability of packaging companies to price their products competitively in the paperboard packaging market. This can potentially limit the growth and profitability of paperboard packaging manufacturers.

Market Opportunity - Technological Advancements in Paperboard Packaging

One significant opportunity for the paperboard packaging market lies in the ongoing technological advancements in packaging materials and processes. Paperboard manufacturers are continuously innovating to develop novel grades of paperboard that are lighter in weight, provide better strength and barrier properties, and are more sustainable. For instance, the development of moisture resistant coated paperboards has enabled safer packaging of food and beverage products without compromising on barrier properties.

Similarly, nano-enabled paperboard offers enhanced strength without additional material usage. On the production front, automated packaging lines integrated with robotics, IoT, and data analytics are improving efficiencies. Advancements like digital printing and customization technologies allow for more versatile and targeted packaging designs.

The evolving customer demands for sustainable and smart paperboard packaging present a major opportunity for manufacturers to innovate differentiated products. Technological innovations help enhance paperboard attributes as well as efficiencies, thereby expanding market prospects.