Plastic Alternative Packaging Market Trends

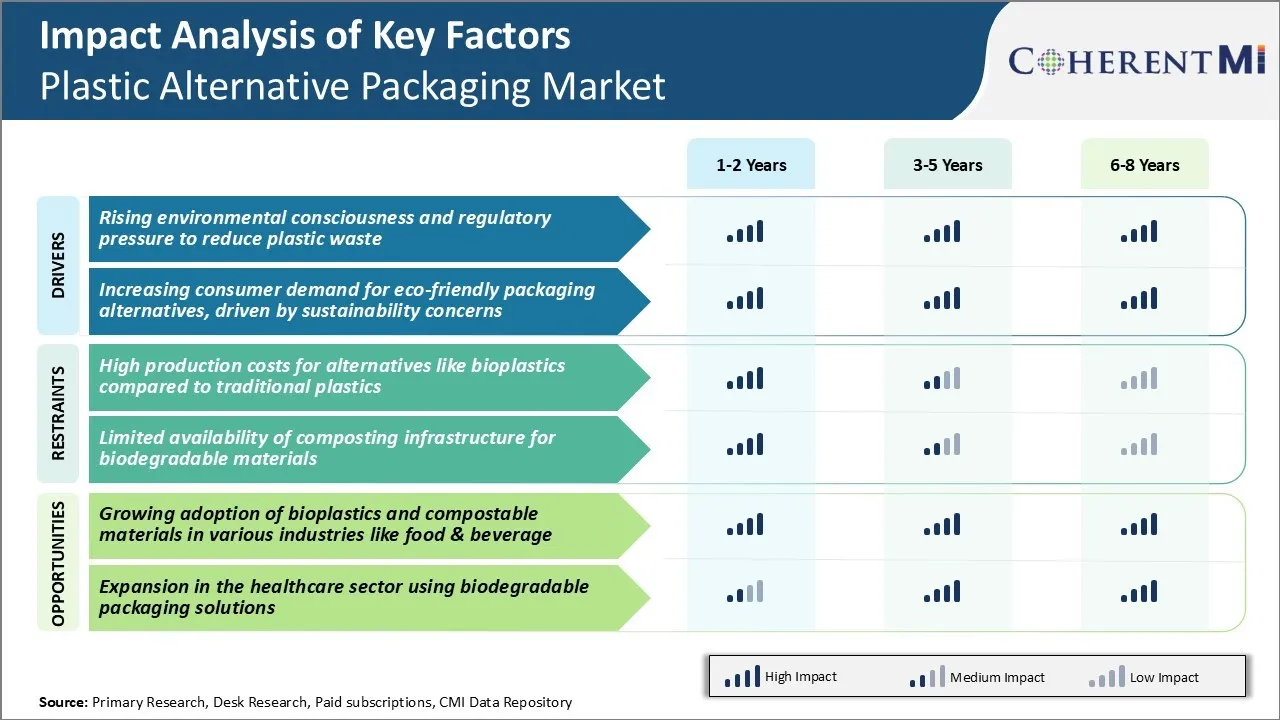

Market Driver - Rising Environmental Consciousness and Regulatory Pressure to Reduce Plastic Waste

Environmental concerns related to plastic pollution have grown exponentially in recent years. Plastic waste has become one of the most pressing environmental issues globally, with an estimated 300 million tons of plastic waste being produced every year.

Governments worldwide have introduced regulations to tackle the plastic waste crisis. Some nations have outright banned specific single-use plastic items like straws, bags and cutlery. Many others have implemented taxes or levies on virgin plastic production. Compliance with regulatory norms is driving large corporations to look beyond conventional plastics for their packaging needs, creating growth avenues for the plastic alternative packaging market.

The need to be socially responsible as well as follow regulatory mandates will continue propelling the adoption of plastic alternative packaging materials. While plastic pollution remains an enormous challenge, it is heartening to see consumers and governments around the world taking meaningful action through their choices and policies.

Market Driver - Increasing Consumer Demand for Eco-friendly Packaging Alternatives, Driven by Sustainability Concerns

Consumers today, especially millennials and generation Z, are highly sustainability conscious. Being mindful about reducing one's own plastic footprint through opting for plastic alternative packaging has become a priority for many buyers.

Sustainable brands extensively utilize platforms like Instagram and YouTube to highlight their green credentials and market the environmental benefits of the materials they employ. Furthermore, transparent product information through online research enables discerning customers to identify packaging made from genuinely sustainable sources like plants. They desire materials that are certified compostable or biodegradable.

Labels showcasing a product's recyclability, recycled content, or proximity to natural elements like trees and leaves are attractive selling points. With awareness and change starting at the individual level, today's consumers vote for environmental protection through every purchase.

This paradigm shift driven by end-user sustainability priorities is set to revolutionize packaging design, material innovation, and supplier choices. Consequently, this is expected to drive growth of the plastic alternative packaging market in the coming years.

Market Challenge - High Production Costs for Alternatives like Bioplastics Compared to Traditional Plastics

One of the key challenges facing the plastic alternative packaging market is the high production costs for materials like bioplastics. While bioplastics are more environmentally sustainable since they are produced from renewable biomass sources rather than fossil fuels, the manufacturing costs are significantly higher.

Producing bioplastics at scale requires specialized production equipment and processes that drive up capital expenditures. The key input materials for bioplastics such as corn starch, sugarcane or cellulosic biomass also have higher supply costs than crude oil. These higher raw material procurement costs ultimately make bioplastics more expensive than conventional plastics on a per unit basis.

All of these factors contribute to bioplastics having production costs that are approximately 2-3 times higher than traditional plastic materials like polyethylene and polypropylene currently. The premium pricing of bioplastics has hindered wider adoption by brand owners and restricted the market growth potential.

Market Opportunity – Growing Demand for Plastic Alternative Packaging in Food & Beverage Industry

A significant opportunity for the plastic alternative packaging market is growing adoption of bioplastics and compostable materials in various industries, especially food and beverage. There is increasing pressure on companies in the food and beverage sector to reduce their use of single-use plastics.

Major food and beverage retailers, brands, and restaurant chains are actively searching for plastic alternative packaging materials like bioplastics or pulp-based solutions for their packaging needs. This will help drive higher and more consistent volumes for bioplastic resin manufacturers in the plastic alternative packaging market.

This volume growth will in turn help lower production costs through economies of scale and make bioplastics more cost competitive against traditional plastics over the long run. Consequently, this is expected to create lucrative opportunities in the plastic alternative packaging market.