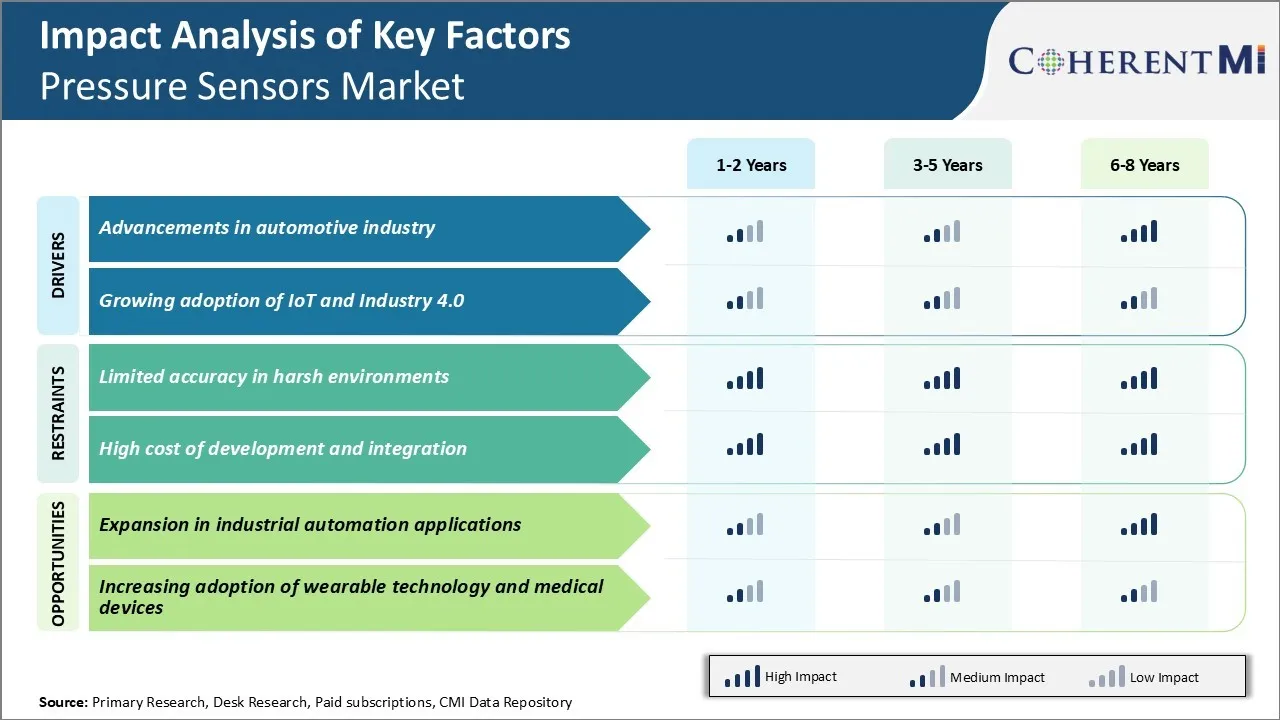

Pressure Sensors Market Trends

Market Driver - Advancements in Automotive Industry

The automotive industry has seen tremendous growth and advancements in the last few decades. Automakers are now focusing on developing autonomous and electric vehicles which incorporate advanced driver-assistance systems. Pressure sensors play a vital role in airbag deployment systems. As autonomous features are improving road safety, airbags are becoming even more crucial. This is increasing the demand for precise and reliable pressure sensors within airbag control units.

The shift towards less complex pumping systems and more electronics indicates that future vehicles will have expanded use of intelligent subsystems. Advancements like brake-by-wire and steer-by-wire replace mechanical components with electro-hydraulic systems. These technologies are completely reliant on pressure sensor feedback.

As a result, leading automakers are collaborating with pressure sensor manufacturers to develop new solutions for emerging application areas. The innovations in autonomous driving and electric mobility are revolutionizing the in-vehicle pressure sensing landscape tremendously. This accelerates the industry's progression and expands opportunities for pressure sensors market players.

Market Driver - Growing Adoption of IoT and Industry 4.0

Trends of Industrial Internet of Things (IIoT) and Industry 4.0 are transforming industrial automation globally. They promote fully integrated smart factories with advanced machine-to-machine communication. This increases operational efficiency drastically by driving real-time process optimization and flexible mass customization. Pressure sensors play an invaluable role in enabling the data collection and decision making capabilities of Industry 4.0. Thereby, this factor remains a key driver for the pressure sensors market.

With interconnected assets delivering live production updates, pressures related to processes, inventory levels, and asset performance are critical parameters. Smart factories also optimize resource utilization based on real-time pressure readings from various manufacturing stages, logistical systems like conveyor belts and warehousing equipment.

The ongoing trend of minimizing human intervention makes autonomous quality assurance equally important. Integrating pressure sensors assists automated quality checks of products and packaging. As industries embrace innovative concepts like cloud computing and cyber-physical systems wholeheartedly, dependence on networked pressure sensors keeps escalating. Their role has become integral to the success of Industry 4.0 revolution.

Market Challenge - Limited accuracy in harsh environments

One of the key challenges faced by the pressure sensors market is providing accurate sensing capabilities in harsh industrial environments. Pressure sensors often struggle to maintain calibration when exposed to high levels of heat, humidity, vibration, or dirt and dust. Harsh manufacturing conditions can cause mechanical stress and degradation of sensing materials over time.

Developing robust sensor designs that can withstand challenging process conditions remains an issue, especially for applications involving extreme temperatures or corrosive media. Protecting the sensitive electronic components from environmental factors without compromising response times or form factor also poses design difficulties.

Addressing reliability concerns through advanced sealing and encapsulation methods is important for the pressure sensors market to better penetrate industries like oil & gas, chemicals, and power generation. Limited accuracy in harsh settings continues to restrict the applicability of pressure sensors for certain critical process monitoring applications with zero-tolerance for measurement errors.

Market Opportunity - Expansion in Industrial Automation Applications

The growth of industrial automation provides a major opportunity for expansion in the pressure sensors market. Automation is being increasingly adopted across industries to improve production efficiencies, product quality, flexibility and safety. As industrial processes become more data-driven, there is rising demand for integrated sensor technologies that can monitor process parameters in real-time.

Applications such as robotic process automation, remote monitoring of oil & gas pipelines, predictive maintenance in manufacturing plants offer scope for incorporating more pressure transmitters, switches, and transducers. With demand for sensors with advanced communication protocols to facilitate integration into Industry 4.0 architectures, pressure sensor vendors can explore opportunities in developing IoT-enabled products.

The need for multi-parameter sensing assemblies combined with increasing use of sensor fusion also provides prospects for suppliers to offer customized solutions. Overall, rapid proliferation of digital technologies in industrial processes creates a conducive environment for pressure sensors market players to expand their presence across mechanical and process industries worldwide.