Proximity Sensor Market Trends

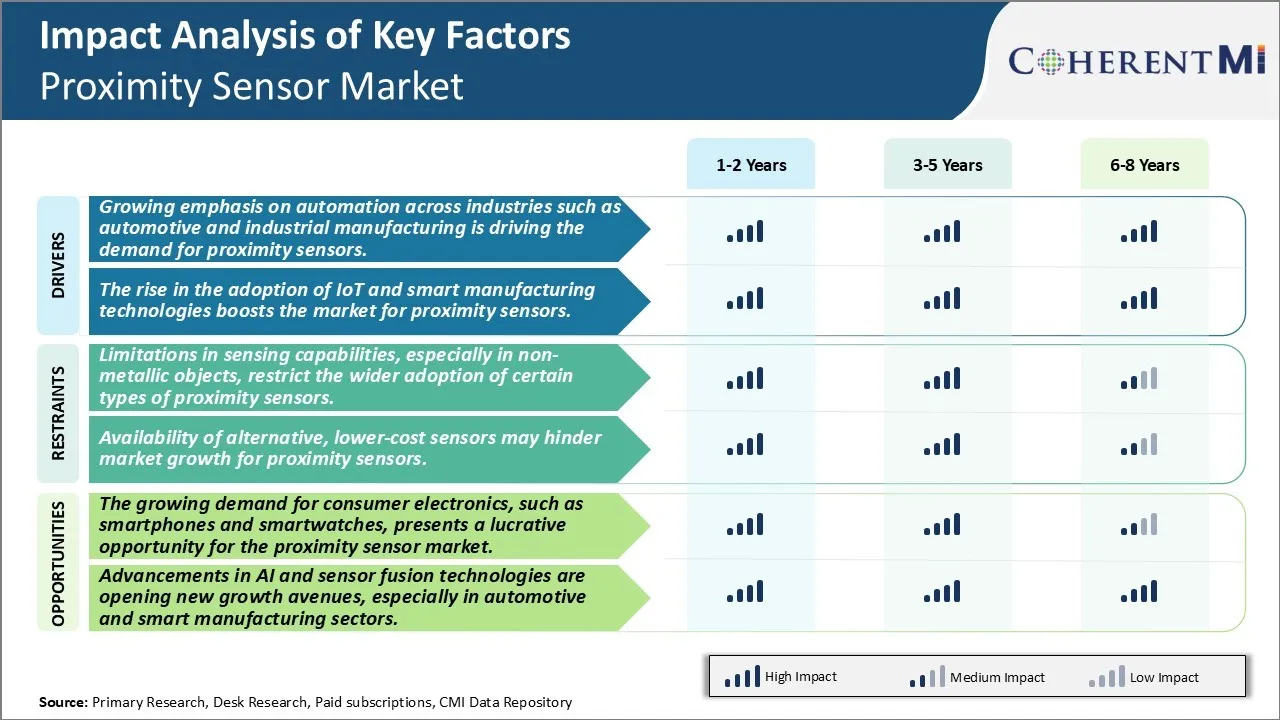

Market Driver - Growing Emphasis on Automation Across Industries Such as Automotive and Industrial Manufacturing is Driving the Demand for Proximity Sensors

The adoption of automation technologies is significantly increasing across major industries globally. Automotive, manufacturing, and industrial sectors are increasingly automating their production processes with advanced robotics, machinery and smart sensors to enhance efficiency, reduce costs, and ensure product quality and safety. Proximity sensors are playing a critical role in enabling automation in these industries. As autonomous guided vehicles, industrial robots, CNC machine tools are employed on large scales for material handling, assembly, quality inspection and packaging, the need for accurate object detection and distance measurement is rising. Proximity sensors allow robotic arms and automated equipment to sense nearby objects without making physical contact. This helps automated systems perform complex assembly, processing and packaging operations smoothly while avoiding collisions that could damage products or disrupt production.

Automakers are at the forefront of automating vehicle production with robots performing welding, painting and other precision tasks. Proximity sensors ensure robots can seamlessly detect and maneuver around other robots, tools and vehicle bodies in production facilities. This level of automation has significantly boosted manufacturing outputs while maintaining strict safety and quality standards. As electric and self-driving vehicles join mainstream vehicle markets, proximity sensors will play a key role in autonomous navigation, collision avoidance, automated parking and other advanced driver assistance capabilities. This will further propel the demand from the automotive industry in the coming years. Overall, the benefits of higher productivity, reduced human errors and increased safety that proximity sensors provide are driving more manufacturing plants and automotive companies to embrace advanced automation technologies.

Market Driver - The Rise of IoT and Smart Manufacturing Encourages Industry Developments

The proliferation of Internet of Things (IoT) technologies and the wider adoption of Industry 4.0 practices termed as smart manufacturing is unveiling new growth avenues for proximity sensor vendors. At the heart of these advanced manufacturing paradigms lies the greater use of connected devices, real-time data collection, cloud computing and analytics to optimize operations and asset utilization. Proximity sensors are being widely incorporated into various IoT devices and smart machines enabling more effective remote monitoring, predictive maintenance and process optimization capabilities. For example, proximity sensors embedded in smarter industrial equipment help detect early signs of wear and tear, monitor material levels in real-time and trigger automated replenishment orders. This brings about significant improvements in overall equipment effectiveness while minimizing downtime.

Key principles of smart manufacturing such as increased data visibility, decentralization of control systems and asset tracking are spurring manufacturers to embrace more smart sensing technologies. Proximity sensors enable autonomous mobile robots, AGVs and smart forklifts to automatically detect their surroundings and navigate production facilities securely. They also allow manufacturers to track important assets, raw materials and finished goods inventory with greater accuracy. This helps smart factories improve transport optimization, reduce spillages and gain better control over production workflows. As Industry 4.0 standards spread, and connectivity of industrial control systems rises, proximity sensors will play a growing role in digitizing manufacturing landscapes and driving higher levels of flexibility, transparency and productivity.

Market Challenge - Limitations in Sensing Capabilities, Especially in Non-Metallic Objects, Restrict the Wider Adoption of Certain Types of Proximity Sensors

One of the main challenges faced by the proximity sensor market is the limitations in sensing capabilities of certain types of proximity sensors, especially when it comes to detecting non-metallic objects. Proximity sensors that use technologies like capacitive, inductive or ultrasonic sensing are often not able to detect the proximity of non-metallic objects as reliably and accurately as metals since their sensing capabilities depend on the electromagnetic or acoustic properties of nearby materials. This affects their scope of applications and restricts the wider adoption of such proximity sensors in situations where non-metallic objects need to be detected. For example, capacitive proximity sensors struggle to detect plastic, wood or glass materials placed near the sensor. Similar issues are faced by inductive and ultrasonic proximity sensors as well. This undermines user experience and trust in the technology when sensors are unable to perform a critical task due to limitations in their sensing methodology. Overcoming these material-based limitations through technological advancements is key to tapping into new application areas and driving the future growth prospects of the proximity sensor market.

Market Opportunity: The Growing Demand for Consumer Electronics, Such as Smartphones and Smartwatches, Presents a Lucrative Opportunity for the Proximity Sensor Market

The proximity sensor market is poised to benefit tremendously from the rising adoption of consumer electronic devices globally. Devices such as smartphones, smartwatches, tablets, gaming consoles and virtual/augmented reality headsets use proximity sensors extensively for functionalities like auto screen-off/wake, gesture controls and biometrics. As new form factors and interaction paradigms are explored in the consumer electronics space, proximity sensing capabilities are becoming an integral part of the user experience. The market for consumer electronic devices has been growing at a rapid pace and is expected to further accelerate with the rollout of 5G networks and proliferation of IoT technologies. This expanding consumer electronics market presents a huge opportunity for proximity sensor vendors to increase volume shipments and tap into the growing demands of OEMs. Further innovations to shrink sensor sizes while enhancing capabilities also allow for proximity sensors to feature even more prominently in emerging categories of wearables and embedded devices.