Radial Flow Pump Market Trends

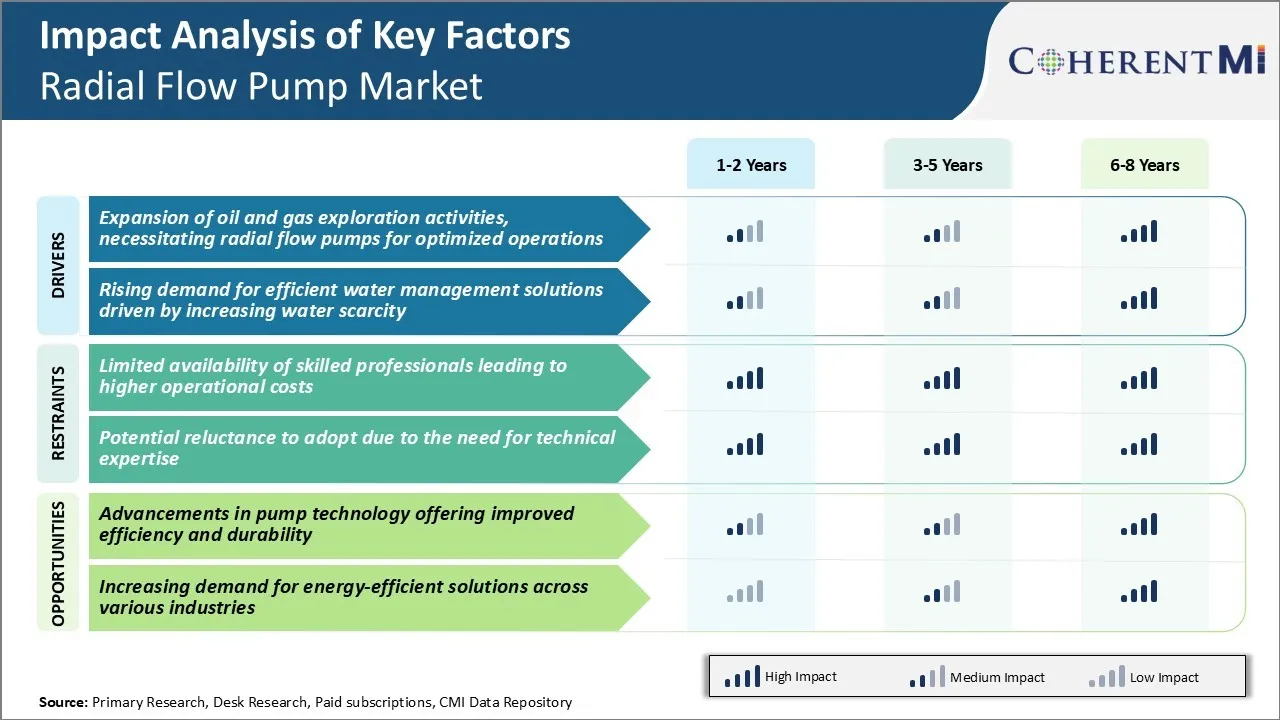

Market Driver - Expansion of Oil and Gas Exploration Activities, Necessitating Radial Flow Pumps for Optimized Operations

The global oil and gas (O&G) industry has been witnessing significant growth over the past few years. It is mainly attributed to increasing energy demand globally along with higher oil prices. Radial flow pumps, with their ability to handle abrasive fluids at high pressures and temperatures, have emerged as a preferred choice for various applications in the industry.

They are extensively used for pumping multiphase fluids consisting of oil, gas, and water during exploration and production activities. Moreover, their non-clogging impeller and sealing mechanism ensures continuous operations are not disrupted. This helps minimize production downtime and reduce operational expenditures for O&G companies.

Radial flow pumps, in particular, have gained popularity owing to their self-priming capabilities. They have proven track record of working reliably in offshore rigs and production platforms. Their advantages over other pump types especially for handling abrasive and multiphase fluids will further solidify their importance in O&G applications. This will drive significant opportunities for radial flow pump market players in the industry.

Market Driver – Rising Demand for Efficient Water Management Solutions Driven by Increasing Water Scarcity

For industrial applications, efficient pumping plays a key role in optimizing water usage and conservation. Radial flow pumps have emerged as a preferred solution due to their energy efficient yet durable operation. Their non-clogging design enables handling of fluids containing solids and slurries without interruptions to flow. This makes them suitable for infrastructure projects related to water distribution and treatment plants.

Radial flow pumps are also well-suited for open channels and surface water pumping applications in large-scale farming. Their self-priming functionality allows dry running and easy restart regardless of fluid levels. This provides uninterrupted water supply critical for productivity.

Innovations focused on enhanced material, hydraulics and mechanical efficiencies are improving the energy performance of radial flow pumps. This, coupled with lower lifecycle costs, is increasing their adoption for global water management initiatives. With water scarcity projected to worsen in the coming years, players in the radial flow pump market are expected to witness lucrative opportunities in the coming years.

Market Challenge - Limited Availability of Skilled Professionals Leading to Higher Operational Costs

One of the key challenges currently being faced by the radial flow pump market is the limited availability of skilled professionals who have expertise in installing, maintaining and repairing these pumps. There is a severe shortage of trained technicians and engineers who understand the internal mechanics and engineering aspects of radial flow pumps. This is primarily due to the lack of focused training programs in this field.

With the demand for radial flow pumps rising in various industries, the challenge of finding competent professionals to handle critical on-site responsibilities has become more serious. As a result, manufacturers in the radial flow pump market and end-users are left with no option but to rely on third-party service contractors for meeting their technical needs.

However, these third-party vendors often charge significantly high costs due to the scarcity of their resource availability in the radial flow pump market. Unless concrete steps are taken to develop the required skillsets internally, this constraint of higher service costs due to limited technical expertise is likely to persist over the coming years.

Market Opportunity - Advancements in Pump Technology Offering Improved Efficiency and Durability

Continuous research and development efforts by major pump manufacturers have led to considerable advancements in radial flow pump technology in recent times. Various innovative design modifications and use of advanced materials have enabled new generations of pumps to deliver substantially higher resource efficiency levels. Similarly, refined hydraulics and flow optimization have significantly boosted the energy efficiency and performance ratings of radial flow pumps.

Such enhancements in product quality directly help end-users to reduce their lifecycle ownership costs. Operating pumps require less maintenance and have longer lifespans. This creates strong buzz and positive word-of-mouth among industrial clients, leading to repeat and referral sales.

Furthermore, the ability of new pumps to use resources more judiciously also provides economic benefits by lowering energy consumption in process applications. Manufacturers are focusing on improvements in efficiency, resilience, and cost economics. Opportunities arising from continually evolving pump technology are therefore quite attractive for buoying the radial flow pump market prospects.