Road Rollers Market Trends

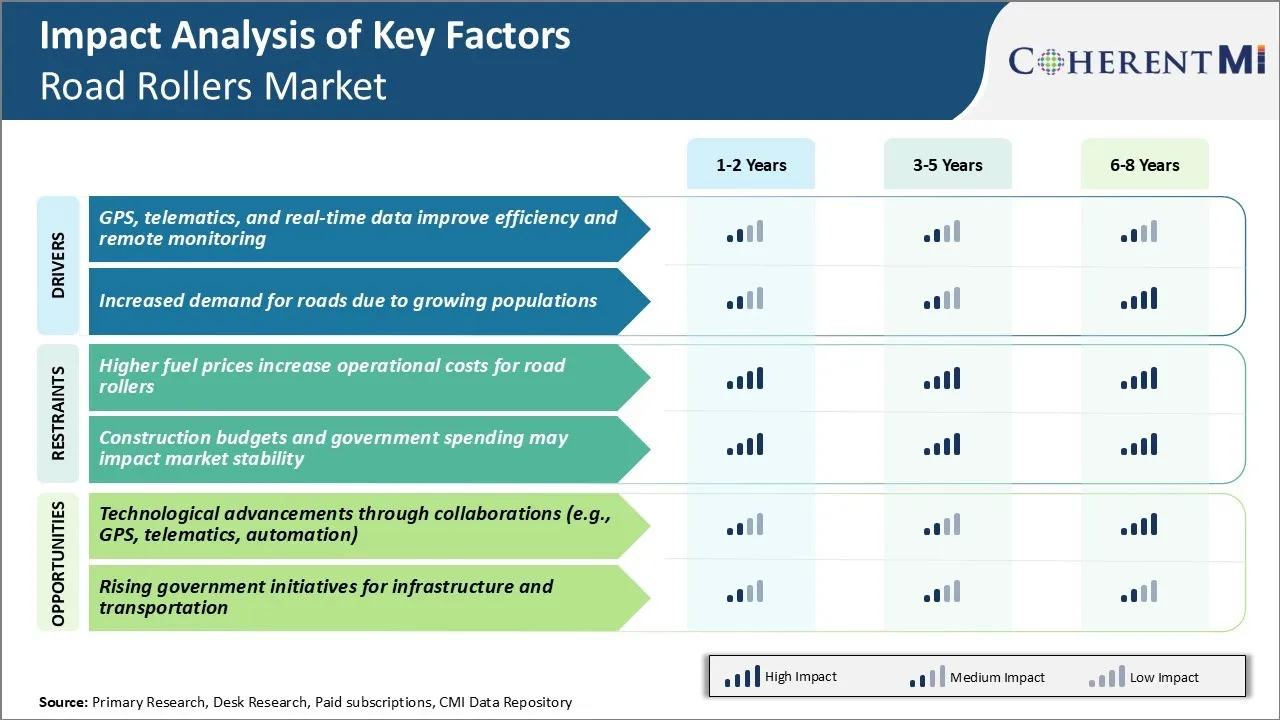

Market Driver - GPS, Telematics, and Real-time Data Improve Efficiency and Remote Monitoring

The ability to track the location and operations of road rollers in real-time has significantly improved work efficiency on construction sites. Telematics is also useful for collaborative scheduling of tasks between multiple pieces of equipment. Site managers no longer need to physically oversee each machine - they can view overall progress from their computers or mobile devices. This level of control and transparency lets them optimize work assignments and ensure all resources are productively deployed.

Operators themselves benefit from telematics as their performance metrics can now be digitally logged. This provides valuable feedback to improve efficiency over time. With data-backed reviews, operators are also more accountable which motivates high standards.

For equipment owners, remote monitoring substantially cuts repair costs by catching malfunctions in early stages before major damage occurs. It allows repairs to be scheduled at the most economical time instead of waiting for breakdown calls. Overall, the integration of real-time tracking systems has heightened productivity, boosted utilization rates, and lowered operating expenses across road construction sites.

Market Driver - Increased Demand for Road Construction

Growing populations both in urban and rural areas have exponentially driven up the need for new road infrastructure and expansion of existing road networks. New expressways, ring-roads, and access-controlled highways are being planned and executed on fast-tracks in highly congested areas. At the same time, smaller regional roads also require continuous widening and strengthening to accommodate heavier vehicular loads and volumes. This indicates a growth potential for companies in the road rollers market.

As long as population trends continue upwards, the requirement for enhanced road connectivity will remain an unstoppable driver of demand. Governments across the world have committed massive infrastructure spending packages towards this imperative over the coming decade. Private contractors are also heavily investing in fleets to gain work in these publicly funded projects.

With road construction emerging as a strategic priority, the number of rollers deployed at any given time is set to multiply manifold. Road roller market players therefore can expect improved sales and rental businesses to achieve sustained growth well into the foreseeable future.

Market Challenge - Higher Fuel Prices Increase Operational Costs

The road rollers market has been facing increasing operational costs due to skyrocketing fuel prices across major global economies. Fuel accounts for a considerable portion of the total cost of ownership for road machinery equipment such as road rollers. In the recent past, fuel prices have witnessed a steady rise owing to various macroeconomic and geopolitical factors.

This surge in fuel expenditure has significantly impacted the profit margins of road construction contractors and rental service providers who utilize road rollers on a daily basis. With fixed contract prices, the additional burden of higher diesel cost is making many road rollers projects financially unviable.

It is also discouraging infrastructure development firms from procuring new road rollers given the uncertainty around long-term fuel price movement. Unless diesel and gasoline prices stabilize in the coming years, the road rollers market growth might remain subdued as operators strive to control operating expenses.

Market Opportunity - Technological Advancements through Collaborations

Major road rollers manufacturers are collaborating with technology companies to integrate advanced connectivity and automation solutions into their products. For instance, some OEMs have enabled functionalities like global positioning system (GPS) tracking and telematics monitoring on new models which provide real-time equipment position and performance data to owners. This allows remote monitoring of road roller fleet health and optimized deployment of assets.

Furthermore, partnerships between automation software developers and road machinery brands are facilitating innovations such as semi-autonomous compaction and partial driving automation. Such technologies have potential to improve overall compaction quality while reducing dependency on skilled operators. Collaborative innovations in areas like guided driving, machine learning-based predictive maintenance can make road construction faster and more cost-effective. If implemented successfully, technological advancements through cross-industry alliances are well-positioned to open new prospects for the road rollers market globally.