Robotic Platform Market Trends

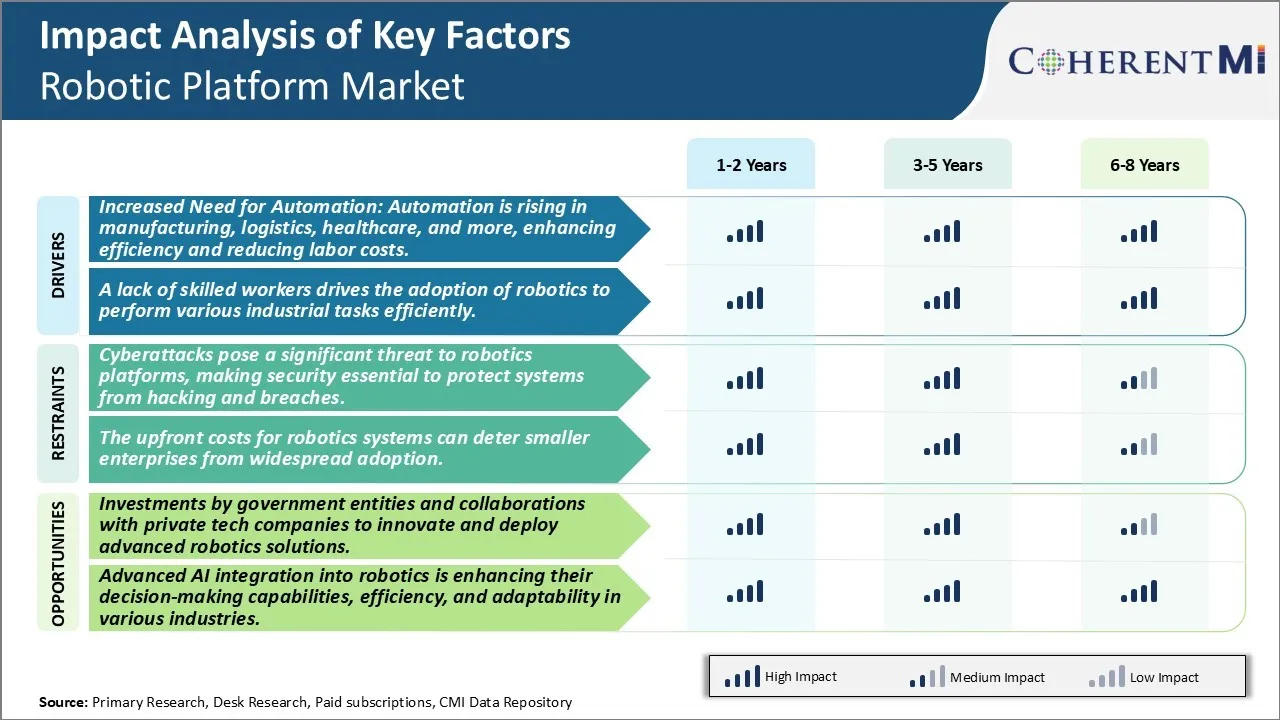

Market Driver - Automation is Rising in Manufacturing, Logistics, Healthcare, and More, Enhancing Efficiency and Reducing Labor Costs

Automation is rising significantly across various industries in order to enhance efficiency and reduce dependence on manual labor. Manufacturing has always leveraged robotics and automation solutions to streamline production processes. However, other sectors like logistics and healthcare are increasingly adopting these technologies. The need to minimize shipping delays and ensure accurate order fulfillment is prompting logistics companies to invest in robotic arms, autonomous vehicles, and other automated solutions for sorting, packaging, and material handling. Similarly, the rising labor costs and shortage of skilled nurses/caregivers are compelling healthcare providers to integrate robot-assisted surgery systems, rehabilitation equipment, and elderly-care robots.

The gains from automation are also evident in areas like e-commerce, where companies are automating various warehouse activities like inventory management, packaging, and delivery route optimization to cope with the surge in online orders during the pandemic. Furthermore, industries that require performing repetitive and hazardous tasks are swiftly automating those jobs. For instance, production lines involving welding or painting automobiles are now dominated by industrial robots. Their deployment has not only improved workplace safety but also increased production capacity and consistency in quality. Overall, the tangible benefits of automation in boosting productivity and reducing dependence on human labor are validated by measurable returns, encouraging more organizations across the global economy to incorporate robotic systems.

Market Driver : Lack of Skilled Workers Drives the Adoption of Robotics

Many industries worldwide are struggling with an acute shortage of workers with technical skills and expertise. While the average educational qualification of the workforce is rising globally, skilled technicians and engineers with experience in operating industrial machinery or programming automation solutions are still in short supply. This talent crunch presents operational challenges for manufacturers involved in metal fabrication, automotive production, food processing, and other such activities that require skilled human labor on the plant floor. Due to difficulties in recruiting and high turnover rates, companies end up losing valuable time and money while the production process remains disrupted.

To overcome this issue, there is a growing Open job roles and equip production lines with robotic systems that can perform tasks more efficiently as well as consistently without taking breaks. Robots do not require remuneration for overtime work or leaves and can seamlessly integrate with one another on a digitally connected factory floor. Their deployment can help establish a stable, optimized production workflow throughout the year while eliminating dependencies on an uncertain labor market. Furthermore, automated solutions continue advancing to take over more complex activities traditionally handled by skilled technicians on the shop floor. This expanding functional scope enhances the long-term prospects of robotics adoption as a substitute for human labor in manufacturing and other industrial operations struggling with workforce shortages.

Market Challenge - Cyberattacks Pose a Significant Threat to Robotics Platforms, Making Security Essential to Protect Systems from Hacking and Breaches

One of the major challenges faced by the robotic platform market is security threats posed by increasing cyberattacks. As robots continue to become more advanced and integrated with Internet of Things technologies, they are exposing a larger attack surface for hackers to exploit. Similar to how we see increasing threats targeting computer networks and industrial control systems, robotics platforms are also at risk of security breaches that could compromise sensitive data or disrupt operations. The complex software and network connectivity powering robots offers numerous potential vulnerabilities that can be leveraged by malicious actors. For example, ransomware or other malware could potentially disable robots or steal and encrypt crucial manufacturing data. Given how dependent many industries have become on robotics for automation needs, production downtimes due to cyber incidents could result in massive financial damages. Furthermore, sensitive corporate information collected by robots during their operational workflows may get stolen. This threatens both a company's proprietary technologies as well as customer privacy. To ensure public safety and trust in robotics, manufacturers must devote considerable focus towards bolstering defenses, implementing authentication protocols, conducting security audits, and facilitating prompt updates to address emerging threats. Overall, cybersecurity risks pose a fundamental challenge that requires intensive ongoing efforts to overcome as the robotics industry continues digital transformation.

Market Opportunity: Government and Private Sector Partnerships Present Opportunities

A major opportunity for the robotics platform market lies in collaborative initiatives between government entities and private technology companies. Several governments around the world have launched initiatives and projects focused on innovating and deploying advanced robotics solutions to address critical challenges. For example, funding is being invested to develop robotic assistants for elderly care, autonomous robots for public infrastructure maintenance and inspection, surgical robotic systems for hospitals, and drones or robotic vehicles for domains like agriculture, construction, and transportation logistics. Such large-scale government backed programs provide a massive impetus for robotics startups and established tech players to accelerate research and commercialization. They also help cover risks of developmental investments. Similarly, strategic partnerships between technology leaders and government contractors can help fast-track robotics adoption across key sectors. When the capabilities of private tech innovators are matched with the massive requirements and budgets of various government modernization programs, it creates fertile ground for collaborative robotics projects and new revenue opportunities. If leveraged effectively through multi-party alliances, government funding presents a major driver of market growth and technology advancement.