Weathering Steel Market Size - Analysis

The weathering steel market is estimated to be valued at USD 2.89 Bn in 2025 and is expected to reach USD 4.01 Bn by 2032, growing at a compound annual growth rate (CAGR) of 4.8% from 2025 to 2032. The weathering steel market is expected to witness positive trends over the next few years. Increasing investments in infrastructure development and growing prominence of sustainable construction materials will boost adoption of weathering steel.

Market Size in USD Bn

CAGR4.8%

| Study Period | 2025-2032 |

| Base Year of Estimation | 2024 |

| CAGR | 4.8% |

| Market Concentration | Medium |

| Major Players | ArcelorMittal S.A., BlueScope Steel Ltd., Tata Steel, Nippon Steel Corporation, SSAB Corporation and Among Others |

please let us know !

Weathering Steel Market Trends

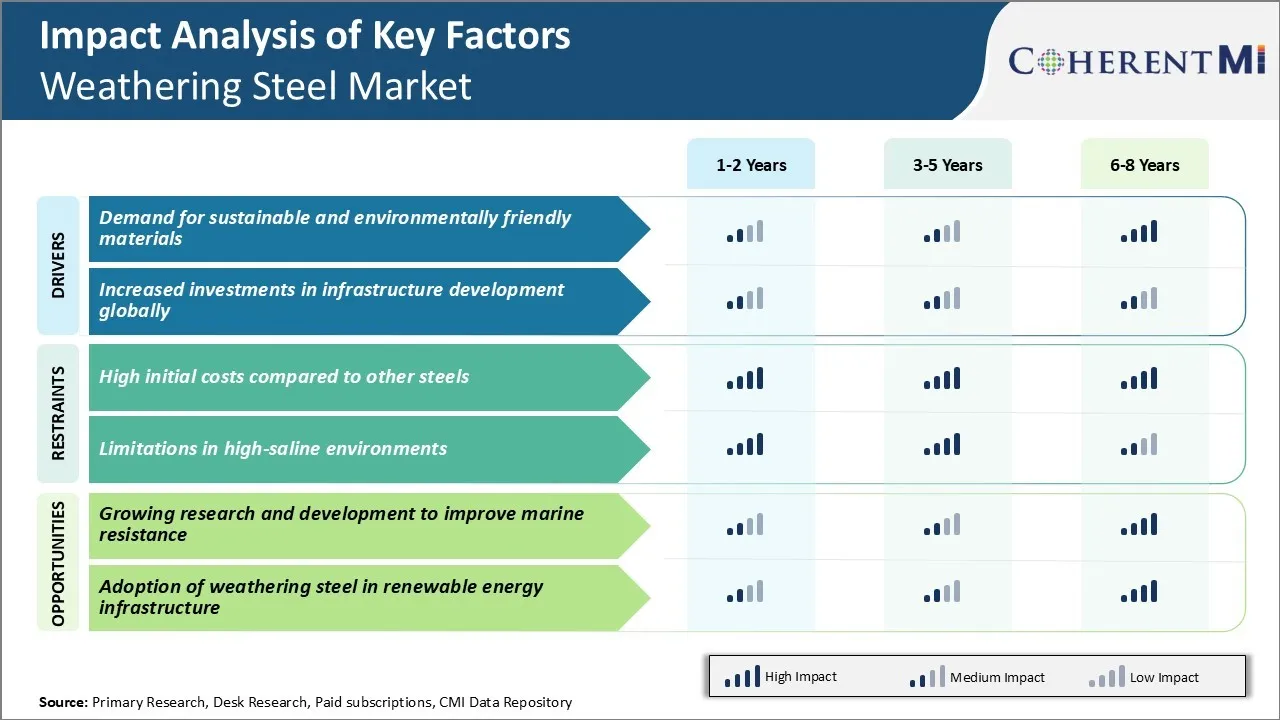

Market Driver - Demand for Sustainable and Environmentally Friendly Materials

The use of traditional building materials like regular carbon steels has been under scrutiny in recent years due to their environmental impact. Weathering steels were developed as a more sustainable alternative that required less maintenance and formed a stable rust layer when exposed to air which helped protect the material from further corrosion. There is growing demand from builders, architects as well as regulators to incorporate materials that reduce carbon footprint and are less taxing on the environment over the lifecycle of a structure.

Weathering steels have gained popularity as they eliminate the need for priming and painting and any repainting work later on. The self-protecting rust layer has beneficial implications. It means lesser use of primers, paints and other corrosive-resistant coatings that involve toxic chemicals. Less repainting work translates to lower long-term maintenance costs. It also helps projects adhere better to various sustainability certification programs.

Most importantly, the self-healing attribute helps extend the functional lifespan of bridges, towers, and other infrastructure subjected to external elements. This reduces environmental damage due to disposal and rebuilding activities later, which remains a strong driver for the weathering steel market.

Market Driver - Increased Investments in Infrastructure Development Globally

Around the world, governments and private organizations have been ramping up investments in building new or improving the existing public infrastructure. Several developing nations in Asia and Africa in particular have ambitious plans for infrastructure development over the next decade. At the same time, even mature markets like Europe and North America are undertaking large-scale overhauls of critical infrastructure built during the post-war years which are nearing the end of their lifespans.

Weathering steels see higher demand whenever iconic and large infra projects requiring heavy-duty structural materials commence. They suit applications ranging from bridge superstructures, light poles, cargo containers and outdoor signage since they eliminate needs for painting and offer corrosion resistance. Advantageous life cycle cost profile of weathering steel has made them a preferred choice especially for major projects having tight budgets and deadlines.

Infrastructure spending maintains an upward trajectory in most regions driven by post-pandemic stimulus packages. So, there are increased opportunities over the coming years in weathering steels market to be specified for various megaprojects.

To learn more about this report, Download Free Sample Copy

To learn more about this report, Download Free Sample Copy

Market Challenge - High Initial Costs Compared to Other Steels

One of the key challenges facing the weathering steel market is its relatively high initial costs compared to conventional steels. The upfront material and installation costs associated with weathering steel tend to be higher than common steel grades. The specialized alloying elements such as copper that are added to the steel composition to impart corrosion resistance drive up raw material prices.

Additionally, as weathering steel undergoes several proprietary production processes involving controlled rolling and annealing, these translate into increased manufacturing costs for vendors. Furthermore, projects may require more weathering steel material compared to normal steel to achieve the necessary thickness due to its lower yield strength.

All these factors contribute to weathering steel being around 10-15% pricier than carbon steel on a per ton basis. The higher costs have limited its uptake in price-sensitive, low budget construction projects. For weathering steel to truly compete with other alternatives on commercial terms, additional cost reduction measures across the supply chain are necessary.

Market Opportunity - Growing Research and Development to Improve Marine Resistance

One major opportunity for the weathering steel market lies in ongoing research and development efforts focused on enhancing the product's marine resistance properties. Currently, weathering steel cannot be used in deeply submerged, immersion conditions due to limitations in its ability to withstand harsh saline environments. However, industry players and research institutes have been investigating new alloy designs and metal pretreatment methods to augment weathering steel's compatibility with marine applications.

Some initiatives involve using higher levels of copper, molybdenum and other elements to bolster resistance to corrosion from saltwater splashes and sprays. Other approaches work on improving the steel's passive film behavior and reformation kinetics in contact with seawater.

If successful, such R&D endeavors could potentially open up whole new demand avenues for weathering steel in end-use industries like shipbuilding, offshore oil and gas infrastructure as well as port and harbor facilities. Achieving enhanced marine corrosion resistance would substantially widen weathering steel market potential and opportunities for revenue growth in weathering steel market globally going forward.

Key winning strategies adopted by key players of Weathering Steel Market

Product innovation: Developing new and improved product grades has helped players in the weathering steel market gain an edge.

Geographic expansion: Leading players like SSAB, ArcelorMittal and POSCO have expanded their weathering steel production and sales footprint globally over the past decade to tap emerging markets.

Strategic partnerships: Players have partnered with engineering and construction giants to secure large bulk orders. For example, in 2020 Tata Steel signed a long-term supply agreement with L&T to provide weathering steel for metro rail projects.

Mergers and acquisitions: Consolidation in the weathering steel market has allowed companies to exploit economies of scale.

Advanced processing technologies: Adopting manufacturing technologies like thermomechanical controlled processing has allowed players to enhance weathering steel qualities like strength and corrosion resistance.

Segmental Analysis of Weathering Steel Market

To learn more about this report, Download Free Sample Copy

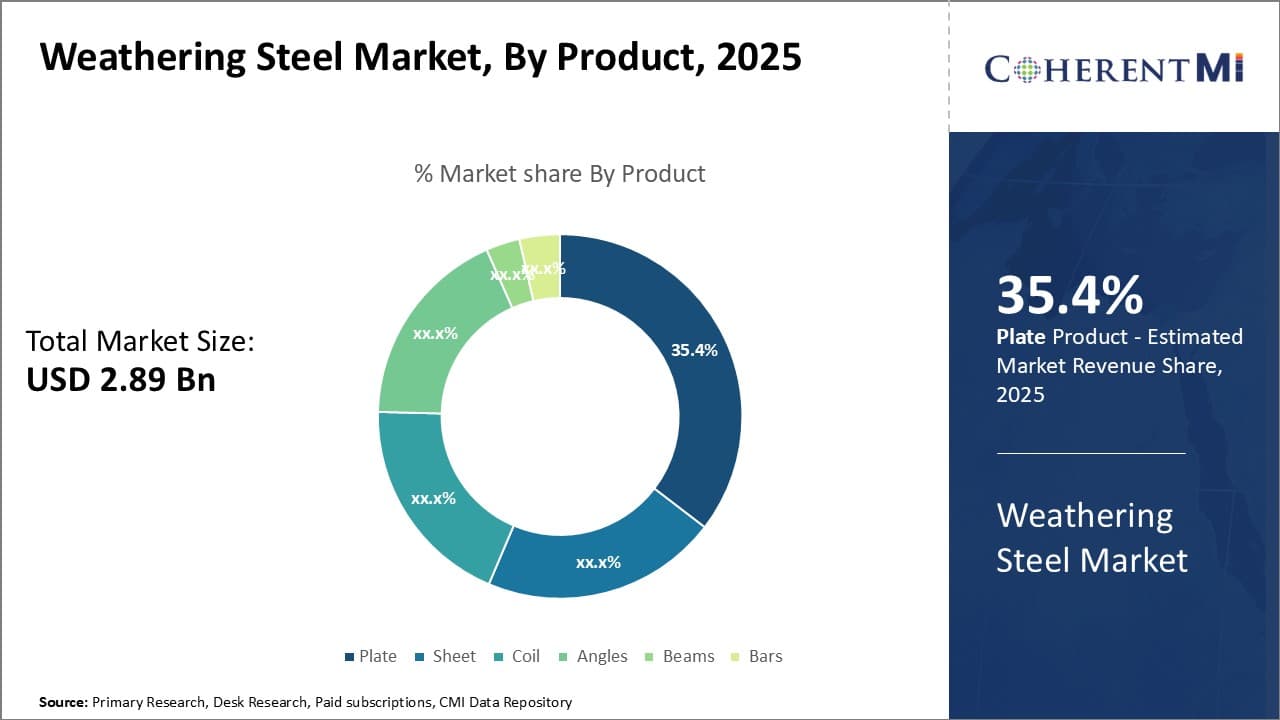

Insights, By Product: Plate Dominates the Product Segment Due to Robust Demand in Construction

To learn more about this report, Download Free Sample Copy

Insights, By Product: Plate Dominates the Product Segment Due to Robust Demand in Construction

Within the weathering steel market segmented by product, plate accounts for 35.4% share in 2025. This is primarily because plate sees the strongest demand from the lucrative construction industry. Construction applications require heavy-duty steel plate that can withstand weathering without maintenance.

Weathering steel plate is a cost-effective solution for buildings, bridges, and other structures since it does not need coatings or repainting like conventional steel. This significantly reduces long-term maintenance costs over the lifespan of the structure. Weathering steel plate is frequently used in the superstructure of bridges as it maintains its strength even after decades of weather exposure.

Additionally, plate fabrication produces less scrap material compared to other products like sheet, coil or bars, bringing down raw material costs for construction projects. With the consistent growth of the construction sector worldwide, especially in developing nations, demand for plates in weathering steel market will rise steadily in the coming years.

To learn more about this report, Download Free Sample Copy

To learn more about this report, Download Free Sample Copy

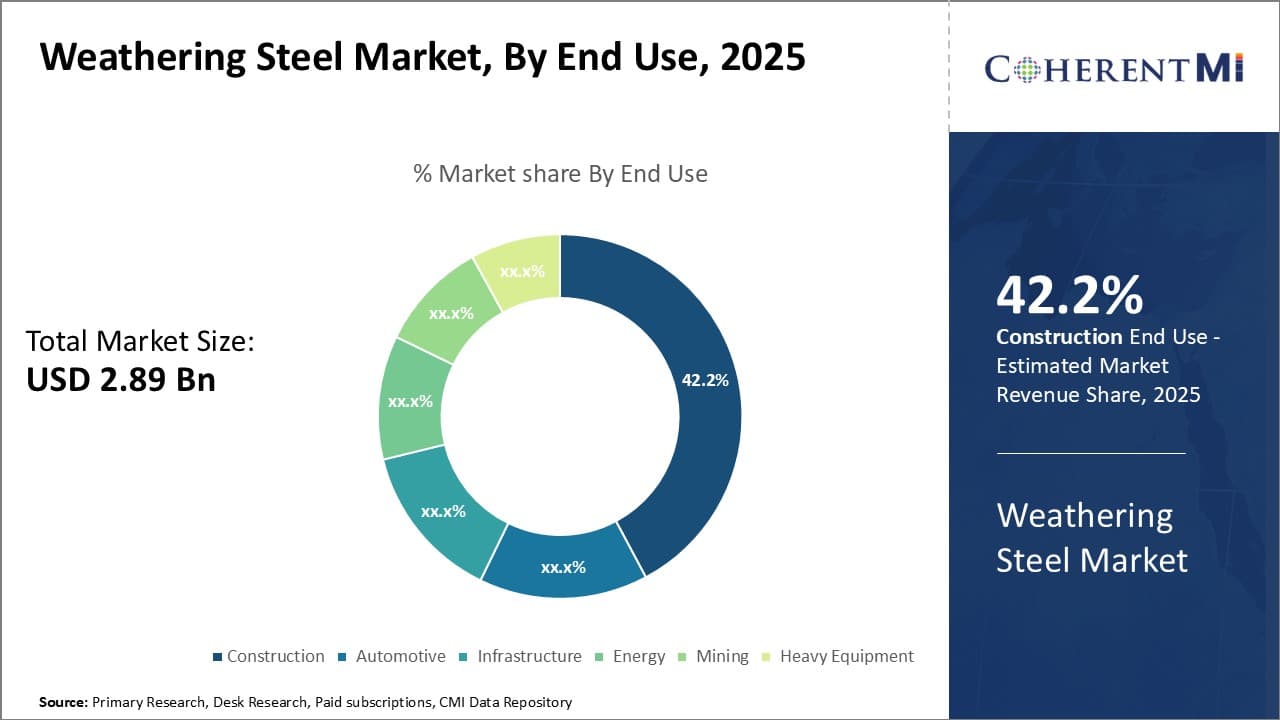

Insights, By End Use: Construction Sector Fuels Demand in the End Use Segment

Within the weathering steel market segmented by end use, construction accounts for 42.2% share. This can be attributed to the material qualities of weathering steel that make it highly suitable for building applications. As a durable material that does not require maintenance coatings, weathering steel significantly reduces life-cycle costs for structural components used in buildings, bridges, industrial construction, and other infrastructure.

Additionally, weathering steel develops a rusted brown patina over time that closely matches surrounding environments, providing an aesthetically-pleasing finish for structures. This has increased its popularity for convention centers, sports arenas, government buildings and other architectural projects.

With rapid urbanization and infrastructure development worldwide, investment in the construction of residential and commercial real estate remains robust. This continues to stimulate demand for weathering steel from the construction sector, making it the key end user segment of weathering steel market.

Additional Insights of Weathering Steel Market

- The adoption of weathering steel in the construction of iconic bridges has increased due to its aesthetic appeal and longevity. For example, several new bridges in Europe and North America have utilized weathering steel to reduce long-term maintenance costs.

- The Asia-Pacific region is expected to witness the highest growth rate in the global weathering steel market due to rapid industrialization and urbanization.

- Approximately 60% of weathering steel consumption is attributed to the building and construction industry.

Competitive overview of Weathering Steel Market

The major players operating in the weathering steel market include ArcelorMittal S.A., BlueScope Steel Ltd., Tata Steel, Nippon Steel Corporation, SSAB Corporation, Central Steel Service, Hobart Brothers, JFE Steel Corporation, Masteel UK, Zahner Company, United States Steel Corporation, POSCO (formerly Pohang Iron and Steel Company), JFE Steel Corporation, HBIS Group and Hyundai Steel Co., Ltd.

Weathering Steel Market Leaders

- ArcelorMittal S.A.

- BlueScope Steel Ltd.

- Tata Steel

- Nippon Steel Corporation

- SSAB Corporation

Recent Developments in Weathering Steel Market

- In May 2024, TW Ryan Architecture completed the Four Roof House, a wildfire-resistant residence in central Montana. Situated on a remote bluff near Helmville, the 5,000-square-foot home features a Corten steel exterior, known for its durability and fire-resistant properties.

- In April 2024, ArcelorMittal introduced a saline-resistant weathering steel designed specifically for offshore structures. This development was highlighted in an award-winning poster presentation by senior project engineer Krista Van den Bergh at WindEurope 2024 in Bilbao, Spain.

Weathering Steel Market Segmentation

- By Product

- Plate

- Sheet

- Coil

- Angles

- Beams

- Bars

- By End Use

- Construction

- Automotive

- Infrastructure

- Energy

- Mining

- Heavy Equipment

Would you like to explore the option of buying individual sections of this report?

Vidyesh Swar is a seasoned Consultant with a diverse background in market research and business consulting. With over 6 years of experience, Vidyesh has established a strong reputation for his proficiency in market estimations, supplier landscape analysis, and market share assessments for tailored research solution. Using his deep industry knowledge and analytical skills, he provides valuable insights and strategic recommendations, enabling clients to make informed decisions and navigate complex business landscapes.