Aircraft Engine Market Size - Analysis

The aircraft engine market is estimated to be valued at USD 118.73 Bn in 2025 and is expected to reach USD 204.80 Bn by 2032, growing at a compound annual growth rate (CAGR) of 8.1% from 2025 to 2032. The aircraft engine market is expected to witness positive growth over the forecast period supported by factors such as burgeoning international tourist arrivals and domestic air traffic.

Market Size in USD Bn

CAGR8.1%

| Study Period | 2025-2032 |

| Base Year of Estimation | 2024 |

| CAGR | 8.1% |

| Market Concentration | High |

| Major Players | General Electric Company (GE Aviation), Rolls-Royce Holding PLC, Pratt & Whitney, Honeywell International Inc., Safran Aircraft Engines and Among Others |

please let us know !

Aircraft Engine Market Trends

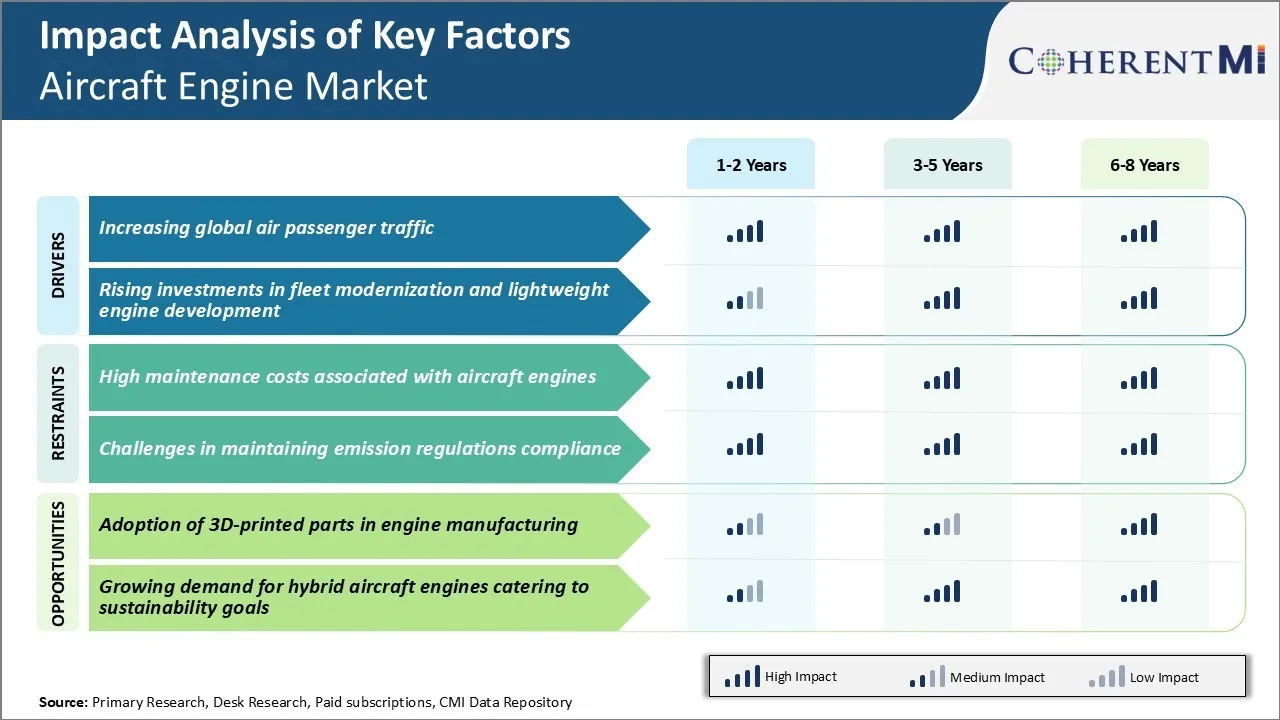

Market Driver - Increasing Global Air Passenger Traffic

According to estimates from various industry sources, the number of passengers flying every year is projected to double over the next 20 years, reaching an estimated 8.2 billion by 2037. Globalization is also acting as a driver as more companies set up offices and conduct business across borders which necessitates intercontinental travel.

All these favorable trends are generating huge opportunities for aircraft and aircraft engine manufacturers to expand their fleets to match this capacity expansion by airlines. Sustained growth in passenger numbers means airlines need to acquire new fuel-efficient aircraft fitted with latest generation engines to replace aging planes as well as expand their networks to cater to new markets.

This stable increase in air traffic is expected to drive significant demand for new commercial aircraft engines across all regions over the next two decades. This will continue to boost growth of the global aircraft engine market.

Market Driver - Rising Investments in Fleet Modernization and Lightweight Aircraft Engine Development

In response to rising environmental regulations aimed at curbing carbon emissions, aircraft manufacturers have been making big investments in technology innovation. Players in the aircraft engine market focus on developing newer generation aircraft engines that burn less fuel and emit lesser greenhouse gases.

A major area of focus has been on developing lightweight aircraft structures and engines through usage of advanced composite materials and design optimizations. Similarly, aircraft engine makers are striving to build advanced lightweight engines with fewer parts through coordinated investments in engineering simulation tools, advanced alloys and additive manufacturing.

Fleet modernization offers dual benefits of meeting environmental norms as well as improving the bottom-line economics for carriers. This is spurring healthy demand for latest engine technologies from airlines looking to green their operations. Original equipment manufacturers are actively engaged in product development activities to capitalize on this upcoming replacement and modernization cycle.

To learn more about this report, Download Free Sample Copy

To learn more about this report, Download Free Sample Copy

Market Challenge - High maintenance costs associated with aircraft engines

One of the major challenges in the aircraft engine market is the high maintenance costs associated with aircraft engines. Aircraft engines are complex machines that require regular maintenance checks and overhauls to ensure optimum performance and safety. Engine parts experience high stresses and wear and tear due to factors like exposure to extreme climate conditions, vibration, heat and pressure during operation.

Engine overhaul processes require the engine to be removed from the aircraft as well, resulting in aircraft downtime. Additionally, unexpected engine failures also contribute to unplanned maintenance costs. With labor and material costs being high, aircraft engine maintenance poses a huge financial burden for airlines.

According to estimates, maintenance, repair and overhaul expenses account for over 20% of total operating costs for many airlines. This remains a major challenge for the sustainment of profitable operations in the aircraft engine market.

Market Opportunity - Adoption of 3D-printed Parts in Engine Manufacturing

One of the key opportunities for the aircraft engine market is the increasing adoption of 3D-printed parts in engine manufacturing and maintenance. 3D printing or additive manufacturing allows the complex internal passages, chambers and components of an aircraft engine to be produced with precision directly from CAD files without relying on labor-intensive machining.

Aircraft engine manufacturers are now actively exploring the use of 3D printing to produce fuel nozzles, turbine blades, combustor parts etc. directly at shop floors. Use of 3D printed parts is gaining popularity in engine maintenance as well, as it facilitates on-demand manufacture of replacements for high-wear components. This helps minimize aircraft downtime and delays. The customizable nature of 3D printing also supports build-to-print business models.

Wider adoption of 3D printed parts offers opportunities to optimize engine designs, reduce production cycles and costs as well as provide a boost to the aftermarket services. It has potential to be a major game changer for the aircraft engine market in the coming years.

Key winning strategies adopted by key players of Aircraft Engine Market

One of the most successful strategies adopted by GE Aviation has been continuous innovation through extensive R&D investments. GE has consistently invested over $3 billion annually in R&D since 2010. This helped GE launch new, highly fuel-efficient engine programs like the GEnx and LEAP families between 2008-2014.

Pratt & Whitney has followed an aggressive market expansion strategy. Between 2015-19, it strategically targeted airframers like Mitsubishi and Embraer to supply engines for their new aircraft programs like MRJ and E-Jets E2. New programs Lockheed, and Irkut helped increase Pratt's order backlog by over 40%.

Honeywell has strengthened its position through smart acquisitions and diversification beyond engines. In 2018, it acquired aircraft engine components maker UTC Aerospace Systems for $8.8 billion. This provided complementary assets like avionics, mechanical systems and gears. It has also expanded into new business segments like aviation service solutions.

Segmental Analysis of Aircraft Engine Market

To learn more about this report, Download Free Sample Copy

Insights, By Engine Type: Technological Advancements Fuel Turbofan Engine Dominance

To learn more about this report, Download Free Sample Copy

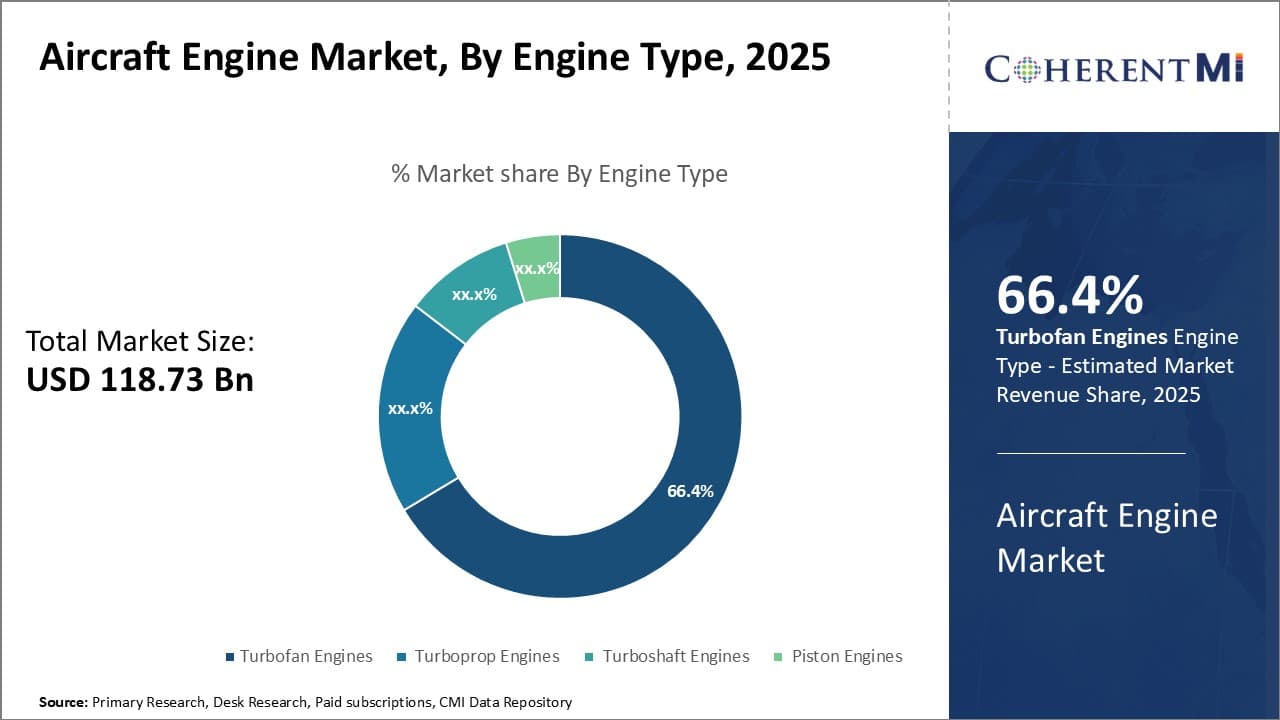

Insights, By Engine Type: Technological Advancements Fuel Turbofan Engine Dominance

In terms of engine type, turbofan engines contributes 66.4% share of the aircraft engine market in 2025, owing to significant technological advancements that have optimized their fuel efficiency. Over the past few decades, turbofan engine manufacturers like GE Aviation and Pratt & Whitney have invested heavily in research and development to reduce specific fuel consumption and noise levels of their engines.

Advanced technologies like geared turbofan designs, composites in fan cases and nacelles, and optimized aerodynamics have substantially boosted the fuel efficiency and reliability of newer generation turbofan engines. Turbofan engines have also benefited from advancements in gas turbine materials and coatings that allow higher combustion and turbine inlet temperatures for improved thrust.

Digital engine controls and 3D printed components have assisted engine operational optimization. These ongoing technological advancements will continue to strengthen turbofan engines' dominance in the aircraft engine market.

To learn more about this report, Download Free Sample Copy

To learn more about this report, Download Free Sample Copy

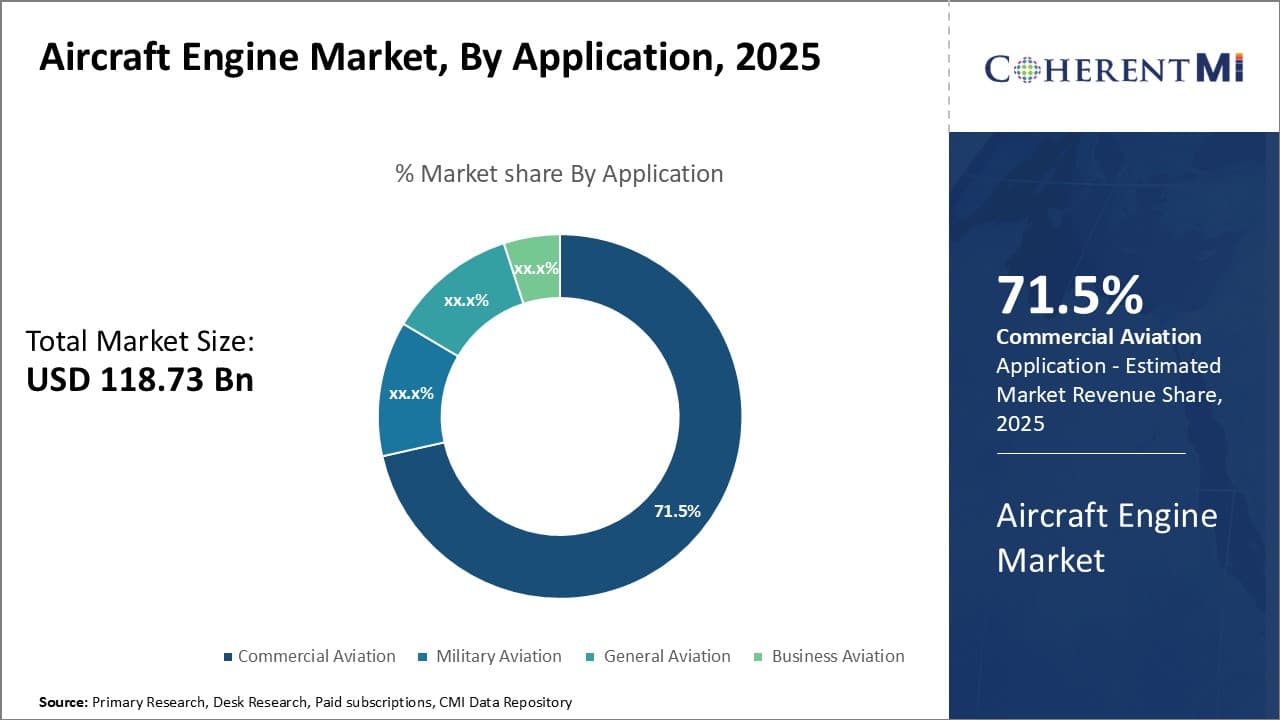

Insights, By Application: Commercial Aviation Demand Drives Engine Market

In terms of application, commercial aviation contributes 71.5% share of the aircraft engine market in 2025, owing to the consistent increase in air passenger traffic worldwide. The commercial aviation sector encompasses airlines, aircraft lessors, and other operators engaged in transporting passengers and cargo on commercial flights.

Rising disposable incomes in emerging economies have allowed a burgeoning middle class to take to air travel for both business and leisure purposes. Low-cost carriers are making air travel more affordable, stimulating demand further. Aircraft manufacturers like Boeing and Airbus continue receiving large orders from airlines to replace aging fleets and add capacity for predicted passenger growth over the next two decades.

Moreover, its needs for high output, fuel efficient engines suitable for continuous operation align well with current technology trends. This sustained pull from the commercial aviation sector will ensure its primacy in the aircraft engine market.

Insights, By Component: Compressor Dominance Driven by Core Engine Function

In terms of component, compressors contribute the highest share of the aircraft engine market owing to its critical role in the gas turbine engine's core operation. The compressor is the essential first component of any aircraft engine which draws in and compresses air at high pressure into the combustion section. Compression ratios of over 30:1 are commonly achieved in modern turbofan engine compressors.

Concentrated R&D is constantly undertaken by engine OEMs to optimize compressor designs for boosted performance through higher pressure ratios and maximum thermodynamic efficiency. Modern compressor technologies include axial and centrifugal multistage configurations, advanced aero profiles, compressor bleed systems, and ceramic composites. Keeping compressors compact but powerful also aids engine packaging.

Ongoing compressor advancements involving 3D printing, alternative topologies, and all-electric designs will drive continued market demand. Collectively, the compressor's critical core function and extensive research emphasis make it the dominating segment among aircraft engine components.

Additional Insights of Aircraft Engine Market

- Hybrid-Electric Propulsion Exploration: Manufacturers are investing in hybrid-electric engine technologies to reduce environmental impact and comply with future emission regulations. This includes research into battery technologies and electric motors integrated with traditional aircraft engines.

- Asia-Pacific Growth Potential: The Asia-Pacific region is projected to witness substantial growth in the global aircraft engine market, due to increasing air travel demand and fleet expansion in countries like China and India. This surge is driven by a growing middle class and increased connectivity.

- Emphasis on Sustainable Aviation Fuels (SAFs): There's a growing trend towards adopting SAFs to reduce carbon footprints. Aircraft engine manufacturers are adapting engines to be compatible with these alternative fuels.

Competitive overview of Aircraft Engine Market

The major players operating in the aircraft engine market include General Electric Company (GE Aviation), Rolls-Royce Holding PLC, Pratt & Whitney, Honeywell International Inc., Safran Aircraft Engines, IHI Corp., Mitsubishi Heavy Industries Aero Engines Ltd, MTU Aero Engines AG, Rostec, Textron Inc., Williams International Co. LLC, CFM International, IAE International Aero Engines AG, and Engine Alliance.

Aircraft Engine Market Leaders

- General Electric Company (GE Aviation)

- Rolls-Royce Holding PLC

- Pratt & Whitney

- Honeywell International Inc.

- Safran Aircraft Engines

Recent Developments in Aircraft Engine Market

- Hybrid-Electric Propulsion Exploration: Manufacturers are investing in hybrid-electric engine technologies to reduce environmental impact and comply with future emission regulations. This includes research into battery technologies and electric motors integrated with traditional aircraft engines.

- Asia-Pacific Growth Potential: The Asia-Pacific region is projected to witness substantial growth in the global aircraft engine market, due to increasing air travel demand and fleet expansion in countries like China and India. This surge is driven by a growing middle class and increased connectivity.

- Emphasis on Sustainable Aviation Fuels (SAFs): There's a growing trend towards adopting SAFs to reduce carbon footprints. Aircraft engine manufacturers are adapting engines to be compatible with these alternative fuels.

Aircraft Engine Market Segmentation

- By Engine Type

- Turbofan Engines

- Turboprop Engines

- Turboshaft Engines

- Piston Engines

- By Application

- Commercial Aviation

- Military Aviation

- General Aviation

- Business Aviation

- By Component

- Compressor

- Turbine

- Gearbox

- Exhaust System

- Fuel System

- By Platform

- Fixed-wing Aircraft

- Rotary-wing Aircraft

- Unmanned Aerial Vehicles (UAVs)

Would you like to explore the option of buying individual sections of this report?

Ramprasad Bhute is a Senior Research Consultant with over 6 years of experience in market research and business consulting. He manages consulting and market research projects centered on go-to-market strategy, opportunity analysis, competitive landscape, and market size estimation and forecasting. He also advises clients on identifying and targeting absolute opportunities to penetrate untapped markets.