CNC Milling Machines Market Size - Analysis

The CNC milling machines market is estimated to be valued at USD 84.85 Bn in 2025 and is expected to reach USD 109.42 Bn by 2032, growing at a compound annual growth rate (CAGR) of 3.7% from 2025 to 2032. The CNC milling machines market is experiencing positive growth driven by an increasing demand from automotive, transportation and precision engineering applications.

Market Size in USD Bn

CAGR3.7%

| Study Period | 2025-2032 |

| Base Year of Estimation | 2024 |

| CAGR | 3.7% |

| Market Concentration | Medium |

| Major Players | Doosan Corp, F-Zimmermann, DMG MORI SEIKI, HYUNDAI WIA, Gleason Corporation and Among Others |

please let us know !

CNC Milling Machines Market Trends

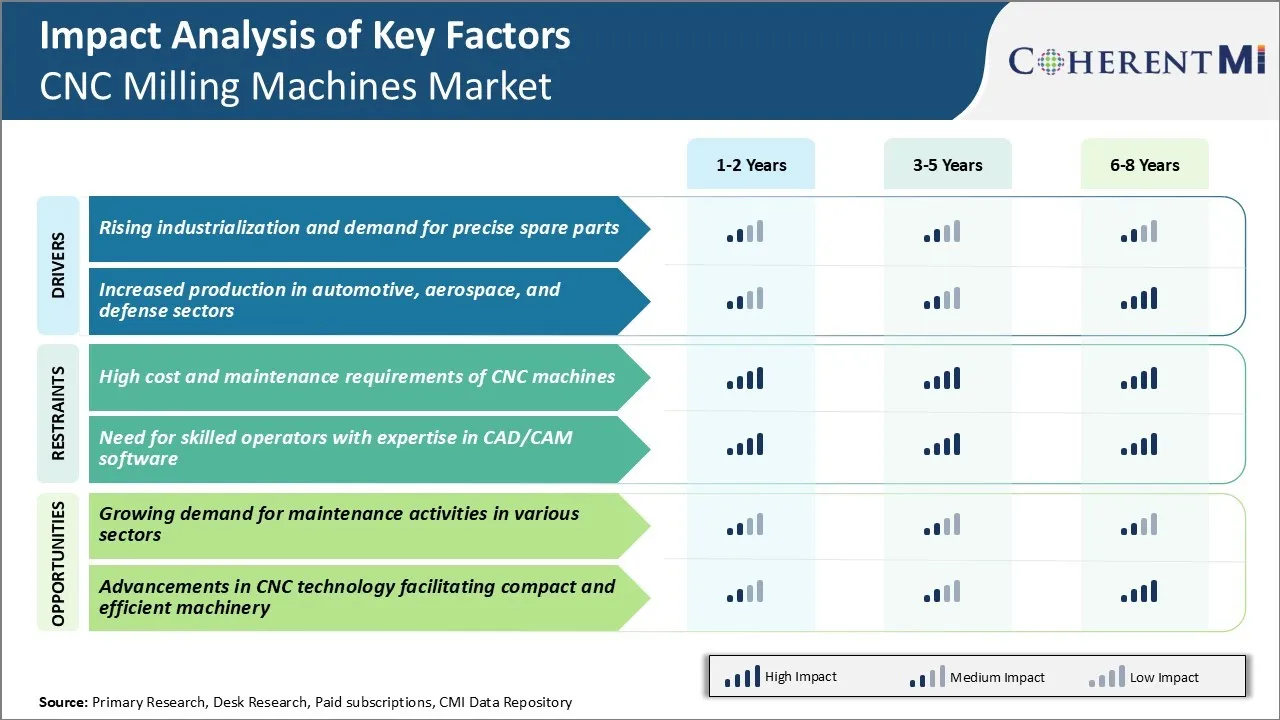

Market Driver - Rising Industrialization and Demand for Precise Spare Parts

As various industries are expanding across regions, there is significant growth in the manufacturing sector. Countries are focusing on developing local manufacturing abilities to improve production and meet the rising demands. This rapid industrialization has increased the need for advanced machining technologies and precise machining of components. CNC milling machines have emerged as a popular choice for factories due to their high-precision capabilities.

With industries constantly searching for optimization of resources, initial investments are carefully evaluated based on long-term returns. CNC milling machines offer mass production of spare components replicating original specifications which fits seamlessly into existing infrastructure.

This improves equipment uptime while minimizing storage and handling costs of excess inventory. Their precision machining abilities also allow creation of complex 3D geometries and near-net-shape production reducing raw material wastage. All such factors lower the total operational expenses for manufacturers justifying investments in advanced CNC milling machines to meet the growing volume of spare parts manufacture.

Market Driver - Increased Production in Automotive, Aerospace, and Defense Sectors

Three prominent industries - automotive, aerospace, and defense have been major adopters of CNC milling machines.

Automakers are aggressively ramping up production capacities to sustain market shares. However, modern vehicles comprise numerous intricate components that push the limits of tolerances and surface finishes achievable through conventional methods. CNC milling machines offer precise cutting abilities for milling complex contours on engine blocks, transmission cases and other critical automobile parts.

Similarly, the aerospace sector has been witnessing strong growth driven by increasing passenger and freight traffic. This has accelerated aircraft procurement programs as well as demand for spare parts globally. With their repeatability, programmable controls, and longer tool lives, CNC milling machines are effectively used by aircraft manufacturers for milling engine components and structural parts.

Likewise, defense budgets are expanding in line with rising geopolitical tensions. Various nations are boosting defense manufacturing capabilities and indigenization. Again, CNC milling technology proves suitable with capabilities to machine military-grade aluminum and steel alloy components. This is expected to contribute to the growth of the CNC milling machines market.

To learn more about this report, Download Free Sample Copy

To learn more about this report, Download Free Sample Copy

Market Challenge - High Cost and Maintenance Requirements of CNC Machines

One of the major challenges faced by the CNC milling machines market is the high cost and maintenance requirements associated with these machines. The high precision components used in CNC milling machines also increase their vulnerability to wear and tear. Regular maintenance and repair work is necessary to keep their precise functioning and minimize downtime.

Frequent replacement of consumable parts like cutting tools further adds to the total cost of ownership. This puts pressure on machine shop owners and manufacturers to invest substantial capital for purchasing and upkeeping CNC milling machines.

High investment requirements pose a major barrier especially for smaller enterprises and businesses in CNC milling machines market to adopt advanced automated machining technologies. The complexity of maintenance procedures also means that specialized technical expertise is required for repairs which increases service charges. Overall, the high purchase and operational costs associated with the machines can discourage their widespread adoption, thereby slowing growth of CNC milling machines market.

Market Opportunity - Growing Demand for Maintenance Activities in Various Sectors

One of the key opportunities for the CNC milling machines market is the growing demand for maintenance activities of these machines across different industry verticals. As installation base of CNC milling machines increases globally, the requirement for periodic maintenance and repairs will also rise significantly. Manufacturing industries where CNC milling sees widespread applications such as automotive, aerospace, electronics and medical devices are expected to majorly drive the growth.

With the emergence of predictive maintenance techniques using IoT and analytics, there is potential to optimize servicing schedules and reduce downtime of machines. This presents lucrative growth prospects for maintenance service providers to expand their service portfolios and clientele. The growing complexity of CNC machine operation also warrants regular training and upskilling of technicians, thereby driving opportunities in the CNC milling machines market.

Key winning strategies adopted by key players of CNC Milling Machines Market

Focus on innovation and technology: In 2020 Haas Automation launched the UMC-750 5-axis machining center with features like a rigid boxway design, high torque spindles and advanced controls. This helped it gain market share.

Expanding product portfolio: In 2018 Doosan Machine Tools launched 10 new machining center models ranging from small to large sizes and with up to 5-axis machining capabilities.

Partnerships and acquisitions: 2017, Yamazaki Mazak acquired Dies toolmaker DMG Mori to extend its range of machine tools. This expanded Yamazaki Mazak's European footprint and diversified its portfolio.

Focus on aftersales support: Haas’ Automation’s service centers located across the world deploy field service engineers who can visit customer facilities for on-site support within 24 hours. This has helped Haas Automation strengthen its customer relationships globally.

Segmental Analysis of CNC Milling Machines Market

To learn more about this report, Download Free Sample Copy

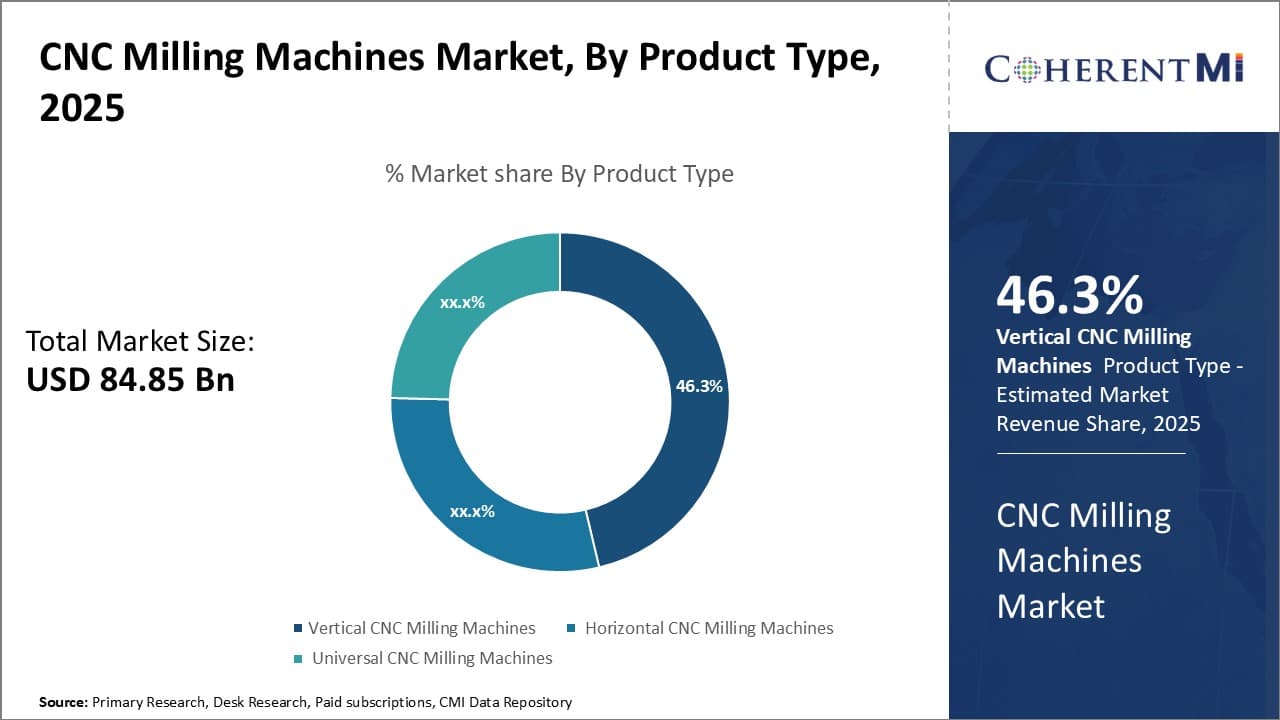

Insights, By Product Type: Precision and Flexibility Driving Vertical CNC Milling Adoption

To learn more about this report, Download Free Sample Copy

Insights, By Product Type: Precision and Flexibility Driving Vertical CNC Milling Adoption

In terms of product type, vertical CNC milling machines contribute 46.3% share of the CNC milling machines market in 2025, owning to the precise machining capabilities and flexibility they offer. Vertical mills excel at milling complex parts with tight tolerances due to their ability to mill flat and narrow surfaces with great accuracy. Their vertical spindle orientation allows for milling surfaces over the full Z-axis range, enabling the production of deep cavity parts. This makes them highly suitable for applications requiring precision milling of 3D contour parts.

Operators can easily adjust the machining angles and access tight spaces with vertical mills. The flexibility to handle a wide range of milling tasks on a single machine lowers production costs and setup times for manufacturers. It has aided their widespread adoption across automotive, aerospace, and other precision manufacturing industries.

To learn more about this report, Download Free Sample Copy

To learn more about this report, Download Free Sample Copy

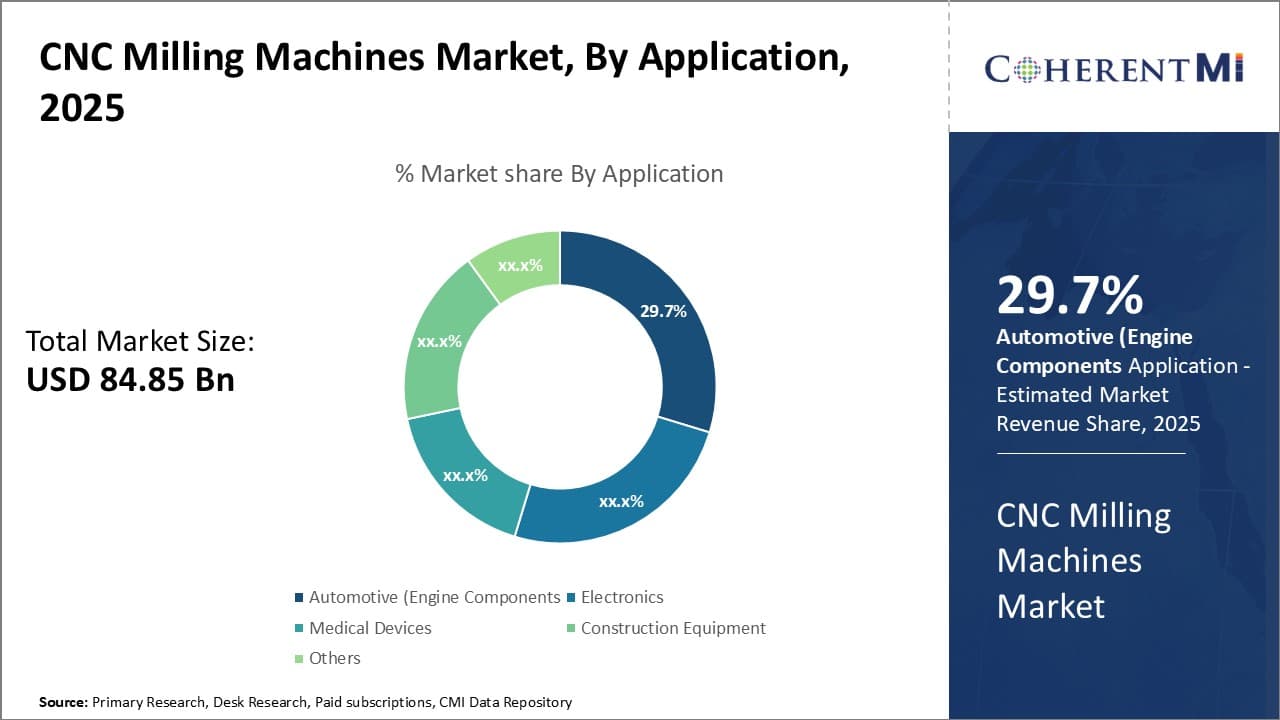

Insights, By Application: Optimizing Production in Automotive Manufacturing

In terms of application, automotive applications contribute 29.7% share of the CNC milling machines market in 2025, as these machines help optimize various automotive production processes. Automakers use CNC milling extensively for machining high-volume engine, transmission and chassis components that require tight dimensional accuracy and repeatability. CNC mills facilitate mass production of parts like pistons, gears, brake discs with high precision. This helps automakers achieve strict quality standards while improving production efficiency.

Additionally, CNC milling supports flexible manufacturing practices in the industry. With their ability to quickly change tooling and process different workpieces, mills allow automotive plants to adjust production plans in response to changing market demands. For instance, they allow flexible machining of common parts for different vehicle models on the same line. This boosts plant capacity utilization and quick fulfillment of batch orders from regional CNC milling machines markets.

Insights, By End-user Industry: Enabling Complex Parts Manufacturing in Industrial Applications

In terms of end-user industry, industrial manufacturing segment contributes the highest share as CNC milling helps machine intricate parts. In industrial manufacturing, CNC mills are extensively used for milling high-precision molds, dies, jigs and fixtures made of metals like tool steel. They facilitate mass production of industrial components with intricate 3D profiles and complex internal features.

Additionally, CNC milling allows optimized machining of critical hydraulic, pneumatic, and structural parts in industrial machinery. This helps increase machining efficiency multi-fold compared to conventional mills.

Moreover, CNC mills support flexible manufacturing needs of industrial OEMs. With their automatic tool changing capability and flexible fixturing, they can rapidly process customized small batches of parts on-demand. This agility helps industrial makers optimize inventory levels while meeting diverse product specifications from their clientele.

Additional Insights of CNC Milling Machines Market

- Asia-Pacific Region: Dominated the CNC milling machines market in 2023 with a 43% share, supported by increased industrial investments and a high demand for precise machinery in electric vehicle production.

- Europe: Projected as the fastest-growing region in the global CNC milling machines market, driven by automation trends in aerospace and defense sectors, improving cost efficiency in production.

- The automotive industry increasingly adopts CNC milling machines for manufacturing complex engine parts, enhancing fuel efficiency and performance.

- In the aerospace sector, CNC milling machines are essential for producing high-precision components required in aircraft, such as turbine blades and structural frames, ensuring safety and reliability.

Competitive overview of CNC Milling Machines Market

The major players operating in the CNC milling machines market include Doosan Corp, F-Zimmermann, DMG Mori Co., Ltd., HYUNDAI WIA, Gleason Corporation, GF Machining Solutions Management, Haas Automation, The CHIRON Group, GROB-WERKE, FANUC Corporation, Okuma Corporation, Hurco Companies, Inc., Makino Milling Machine Co., Ltd., Yamazaki Mazak Corporation, Siemens AG, Mitsubishi Electric Corporation, and JTEKT Corporation.

CNC Milling Machines Market Leaders

- Doosan Corp

- F-Zimmermann

- DMG MORI SEIKI

- HYUNDAI WIA

- Gleason Corporation

Recent Developments in CNC Milling Machines Market

- In September 2024, Haas Automation, Inc. announced the commencement of construction on a new 2.4-million-square-foot manufacturing facility in Henderson, Nevada. This expansion aims to meet the growing global demand for CNC milling machines and underscores Haas Automation's commitment to domestic production.

- In September 2023, during the EMO Hannover 2023 exhibition, FANUC Corporation unveiled its upcoming FS500i-A series CNC system, which is currently under development. This new system is designed to enhance performance and user experience, featuring a new Human-Machine Interface (HMI) that simplifies operations for both seasoned and new users.

- In August 2023, CGTech released VERICUT 9.4, the latest version of its CNC machine simulation software. This update introduced several enhancements, notably the ToolsUnited interface, which provides access to tool and cutting data from over 40 tooling vendors.

- In March 2023, DMG MORI Co., Ltd. introduced a new line of CNC milling machines featuring advanced automation capabilities designed to enhance productivity and minimize downtime in manufacturing processes. These machines offer a range of automation solutions, including workpiece, and pallet handling systems, as well as robotic integration, to streamline operations and improve efficiency.

- In February 2023, Shilpin Machine Tools Pvt. Ltd. organized the 13th DIE AND MOULD INDIA 2024 exhibition at the Bombay Exhibition Center. The event highlighted challenges in polishing and machining, and featured the launch of the Acuka machine, improving precision in CNC milling machines.

CNC Milling Machines Market Segmentation

- By Product Type

- Vertical CNC Milling Machines

- Turret Mills

- Bed Mills

- Horizontal CNC Milling Machines

- Plain Horizontal Mills

- Universal Horizontal Mills

- Universal CNC Milling Machines

- Vertical CNC Milling Machines

- By Application

- Automotive

- Engine Components

- Transmission Systems

- Aerospace & Defense

- Aircraft Components

- Defense Equipment

- Electronics

- PCB Manufacturing

- Semiconductor Components

- Medical Devices

- Surgical Instruments

- Orthopedic Implants

- Construction Equipment

- Hydraulic Components

- Structural Parts

- Others

- Automotive

- By End-User Industry

- Industrial Manufacturing

- Precision Engineering

- Energy & Power

- Oil & Gas

- Others

Would you like to explore the option of buying individual sections of this report?

Ramprasad Bhute is a Senior Research Consultant with over 6 years of experience in market research and business consulting. He manages consulting and market research projects centered on go-to-market strategy, opportunity analysis, competitive landscape, and market size estimation and forecasting. He also advises clients on identifying and targeting absolute opportunities to penetrate untapped markets.