Radial Flow Pump Market SIZE AND SHARE ANALYSIS - GROWTH TRENDS AND FORECASTS (2024 - 2031)

Radial Flow Pump Market is segmented By Product Type (Single-Stage Radial Flow Pumps, Multi-Stage Radial Flow Pumps), By End Use (Agriculture, Constru....

Radial Flow Pump Market Size

Market Size in USD Bn

CAGR3.63%

| Study Period | 2024 - 2031 |

| Base Year of Estimation | 2023 |

| CAGR | 3.63% |

| Market Concentration | High |

| Major Players | KSB SE & Co. KGaA, NEC Air Compressors, EGGER, HIFUNI PUMPS PVT. LTD., Ganga Pumps and Among Others. |

please let us know !

Radial Flow Pump Market Analysis

The radial flow pump market is estimated to be valued at USD 26.01 Bn in 2024 and is expected to reach USD 33.38 Bn by 2031, growing at a compound annual growth rate (CAGR) of 3.63% from 2024 to 2031. Rising energy demand along with growing investments in process industries is expected to drive the radial flow pump market during the forecast period.

Radial Flow Pump Market Trends

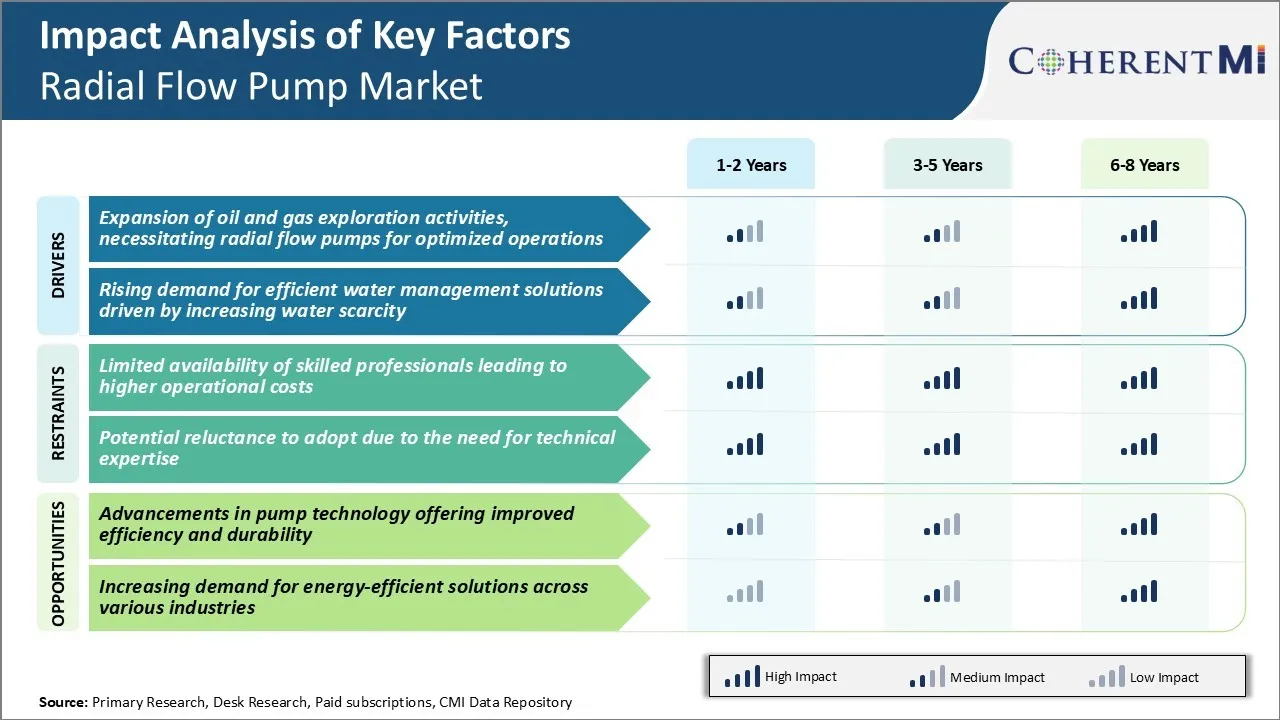

Market Driver - Expansion of Oil and Gas Exploration Activities, Necessitating Radial Flow Pumps for Optimized Operations

The global oil and gas (O&G) industry has been witnessing significant growth over the past few years. It is mainly attributed to increasing energy demand globally along with higher oil prices. Radial flow pumps, with their ability to handle abrasive fluids at high pressures and temperatures, have emerged as a preferred choice for various applications in the industry.

They are extensively used for pumping multiphase fluids consisting of oil, gas, and water during exploration and production activities. Moreover, their non-clogging impeller and sealing mechanism ensures continuous operations are not disrupted. This helps minimize production downtime and reduce operational expenditures for O&G companies.

Radial flow pumps, in particular, have gained popularity owing to their self-priming capabilities. They have proven track record of working reliably in offshore rigs and production platforms. Their advantages over other pump types especially for handling abrasive and multiphase fluids will further solidify their importance in O&G applications. This will drive significant opportunities for radial flow pump market players in the industry.

Market Driver – Rising Demand for Efficient Water Management Solutions Driven by Increasing Water Scarcity

For industrial applications, efficient pumping plays a key role in optimizing water usage and conservation. Radial flow pumps have emerged as a preferred solution due to their energy efficient yet durable operation. Their non-clogging design enables handling of fluids containing solids and slurries without interruptions to flow. This makes them suitable for infrastructure projects related to water distribution and treatment plants.

Radial flow pumps are also well-suited for open channels and surface water pumping applications in large-scale farming. Their self-priming functionality allows dry running and easy restart regardless of fluid levels. This provides uninterrupted water supply critical for productivity.

Innovations focused on enhanced material, hydraulics and mechanical efficiencies are improving the energy performance of radial flow pumps. This, coupled with lower lifecycle costs, is increasing their adoption for global water management initiatives. With water scarcity projected to worsen in the coming years, players in the radial flow pump market are expected to witness lucrative opportunities in the coming years.

Market Challenge - Limited Availability of Skilled Professionals Leading to Higher Operational Costs

One of the key challenges currently being faced by the radial flow pump market is the limited availability of skilled professionals who have expertise in installing, maintaining and repairing these pumps. There is a severe shortage of trained technicians and engineers who understand the internal mechanics and engineering aspects of radial flow pumps. This is primarily due to the lack of focused training programs in this field.

With the demand for radial flow pumps rising in various industries, the challenge of finding competent professionals to handle critical on-site responsibilities has become more serious. As a result, manufacturers in the radial flow pump market and end-users are left with no option but to rely on third-party service contractors for meeting their technical needs.

However, these third-party vendors often charge significantly high costs due to the scarcity of their resource availability in the radial flow pump market. Unless concrete steps are taken to develop the required skillsets internally, this constraint of higher service costs due to limited technical expertise is likely to persist over the coming years.

Market Opportunity - Advancements in Pump Technology Offering Improved Efficiency and Durability

Continuous research and development efforts by major pump manufacturers have led to considerable advancements in radial flow pump technology in recent times. Various innovative design modifications and use of advanced materials have enabled new generations of pumps to deliver substantially higher resource efficiency levels. Similarly, refined hydraulics and flow optimization have significantly boosted the energy efficiency and performance ratings of radial flow pumps.

Such enhancements in product quality directly help end-users to reduce their lifecycle ownership costs. Operating pumps require less maintenance and have longer lifespans. This creates strong buzz and positive word-of-mouth among industrial clients, leading to repeat and referral sales.

Furthermore, the ability of new pumps to use resources more judiciously also provides economic benefits by lowering energy consumption in process applications. Manufacturers are focusing on improvements in efficiency, resilience, and cost economics. Opportunities arising from continually evolving pump technology are therefore quite attractive for buoying the radial flow pump market prospects.

Key winning strategies adopted by key players of Radial Flow Pump Market

Focus on innovation and new product development: Flowserve launched its next-generation Hyspin HXL radial pumps in 2020 that offer improved efficiency and lower maintenance costs. These new products helped Flowserve gain market share. Similarly, Ruhrpumpen launched new submersible pumps under its Creanova brand in 2018 that can handle solids and provide higher flow rates, allowing it to capture more customers.

Target emerging markets: Emerging economies in Asia Pacific and Latin America witnessed rapid infrastructure growth over the last decade. KSB doubled its sales network in China between 2010-2015. Today, the APAC region accounts for over 35% of KSB's revenues, making it a key growth market.

Acquisitions and mergers: Larger players adopted an acquisition-led strategy to gain access to new technologies and geographic territories. Xylem acquired Godwin Pumps and Ecoline Pumps through acquisitions in 2017-2018, enhancing its offerings for dewatering applications. These acquisitions helped players cross-sell products and achieve synergies.

Segmental Analysis of Radial Flow Pump Market

Insights, By Product Type: Cost-effectiveness Drives Demand for Single-stage Radial Flow Pumps

In terms of product type, single-stage radial flow pumps contribute 54.7% share of the radial flow pump market in 2024. This is due to their cost-effectiveness compared to multi-stage pumps. Being a single unit, single-stage pumps have fewer moving parts which reduces manufacturing costs.

Their mechanical configuration requires less capital expenditure and operational maintenance compared to multi-stage pumps with multiple impellers. This makes single-stage pumps a viable option for low pressure or low head applications that do not require high discharge pressure. Their simplicity of design also means energy efficiency is maximized in transferring liquids over short vertical lifts.

As such, single-stage pumps see widespread demand from various industries with basic transfer requirements including agriculture, construction, and water supply where initial costs are prioritized.

Insights, By End Use: Agricultural Intensification Boosts Usage in Irrigation

In terms of end use, agriculture industry contributes 27.2% share of the radial flow pump market in 2024, due to intensification of farming practices globally. Rapid population growth and rising food demand are exerting pressure on limited arable land and water resources. This is leading more farmers to adopt center pivot and drip irrigation techniques that rely heavily on consistent radial flow pump utilization. Their ability to discharge large volumes of water over long durations at minimum pressure enables reliable irrigation of wide plots.

Various governments also offer subsidies for pump sets to enhance crop yields. As climate change impacts weather patterns, irrigation infrastructure built with robust radial flow pump technology provides farmers resilience against drought risks. Investments in pump sets translate to higher income stability for the agricultural sector.

Insights, By Application: Stringent Quality Standards Fuel Water Treatment Pumps

In terms of application, water & wastewater treatment contributes the highest share of the radial flow pump market owing to stringent quality regulations. Radial flow pumps are highly suitable for transfer of potable water and haulage of sewage due to their self-priming functionality and solids-handling capability. Water authorities rely on them to efficiently collect, purify and distribute water as per international guidelines.

Meanwhile, industrialization and urbanization trends globally have escalated wastewater volumes requiring proper treatment before discharge. This upholds demand from municipal corporations and industrial effluent treatment plants.

Additionally, environmental agencies mandate reuse and recycling of processed water which pumps facilitate. Radial flow pumps hence remain integral to sustainable water management initiatives aiding compliance with evolving health and environmental protection standards.

Additional Insights of Radial Flow Pump Market

- India's Kaleshwaram Lift Irrigation Project in Telangana is the world’s largest multi-stage lift irrigation project, showcasing massive applications of radial flow pumps in water management.

- Asia-Pacific’s dominance in the radial pump flow market is attributed to increased industrialization across various sectors, including power generation, which requires reliable fluid management systems.

- The Asia-Pacific region held a 48% share in radial flow pump market in 2023, supported by infrastructure investments in renewable and traditional power plants.

- Pump systems account for approximately 25% of industrial energy consumption, driving the growth of the radial flow pump market.

- Upgradation of existing industrial infrastructure with modern radial flow pumps improves operational efficiency and complies with environmental regulations.

Competitive overview of Radial Flow Pump Market

The major players operating in the radial flow pump market include KSB SE & Co. KGaA, NEC Air Compressors, EGGER, HIFUNI PUMPS PVT. LTD., Ganga Pumps, Ruhrpumpen, Lada Pumps, Siya Pumps, Litostroj Power Group, Grundfos Holding A/S, Xylem Inc., Sulzer Ltd., and Flowserve Corporation.

Radial Flow Pump Market Leaders

- KSB SE & Co. KGaA

- NEC Air Compressors

- EGGER

- HIFUNI PUMPS PVT. LTD.

- Ganga Pumps

Radial Flow Pump Market - Competitive Rivalry, 2024

Radial Flow Pump Market

(Dominated by major players)

(Highly competitive with lots of players.)

Recent Developments in Radial Flow Pump Market

- In July 2023, Xylem Inc. acquired ABC Pumps Ltd., expanding its product portfolio in the wastewater treatment sector. The acquisition enhances Xylem's market presence and technological capabilities.

- In June 2023, ZenWTR unveiled a refreshed brand design to emphasize its dedication to ocean preservation and sustainability. The updated packaging features a blue ombre label, symbolizing the ocean, with the mission statement "Save Our Oceans" prominently displayed.

- In March 2023, Grundfos introduced an energy-efficient radial flow pump tailored for industrial applications, aiming to reduce energy consumption by up to 20%. This initiative aligns with Grundfos's commitment to sustainability, as highlighted in their 2023 Sustainability Report.

Radial Flow Pump Market Segmentation

- By Product Type

- Single-Stage Radial Flow Pumps

- Multi-Stage Radial Flow Pumps

- By End Use

- Agriculture

- Construction & Building Services

- Water & Wastewater

- Power Generation

- Oil & Gas

- Chemicals

- Others

- By Application

- Water & Wastewater Treatment

- Oil & Gas Industry

- Chemical Industry

- Power Generation

Would you like to explore the option of buying individual sections of this report?

Frequently Asked Questions :

How big is the radial flow pump market?

The radial flow pump market is estimated to be valued at USD 26.01 Bn in 2024 and is expected to reach USD 33.38 Bn by 2031.

What are the key factors hampering the growth of the radial flow pump Market?

Limited availability of skilled professionals leading to higher operational costs and potential reluctance to adopt due to the need for technical expertise are the major factors hampering the growth of the radial flow pump market.

What are the major factors driving the radial flow pump market growth?

Expansion of oil and gas exploration activities, growing importance of radial flow pumps for optimized operations, and rising demand for efficient water management solutions are the major factors driving the radial flow pump market.

Which is the leading product type in the radial flow pump market?

The leading product type segment is single-stage radial flow pumps.

Which are the major players operating in the radial flow pump market?

KSB SE & Co. KGaA, NEC Air Compressors, EGGER, HIFUNI PUMPS PVT. LTD., Ganga Pumps, Ruhrpumpen, Lada Pumps, Siya Pumps, Litostroj Power Group, Grundfos Holding A/S, Xylem Inc., Sulzer Ltd., and Flowserve Corporation are the major players.

What will be the CAGR of the radial flow pump market?

The CAGR of the radial flow pump market is projected to be 3.63% from 2024-2031.