圆柱形滚轮轴承市场 规模与份额分析 - 成长趋势与预测 (2024 - 2031)

圆柱形滚轮轴承市场按类型划分(单排卷轮轴承,双排卷轮轴承,四排卷轮轴承,其他),按应用(自动驱动,机械,其他),按地理(北美,拉丁美洲,亚太,欧洲,中东,非洲). 本报告为上述各部分提供了价值(10亿美元)。....

圆柱形滚轮轴承市场 规模

市场规模(美元) Bn

复合年增长率8.1%

| 研究期 | 2024 - 2031 |

| 估计基准年 | 2023 |

| 复合年增长率 | 8.1% |

| 市场集中度 | High |

| 主要参与者 | JTEKT 印度有限公司, NTN公司, SKF( 韩国足协), 沙夫勒印度有限公司, 国家工程工业有限公司(NEI) 以及其他 |

请告诉我们!

圆柱形滚轮轴承市场 分析

全球圆柱形滚轮轴承市场估计价值 25.8美元 2024年学士 预计将达到 48.4美元 203块1,以复合年增长率增长. (CAGR)从2024年到2031年占8.1%.

圆柱滚筒轴承市场预计将在预测期间出现正增长。 工业机械和设备部门的需求日益增加。 精密圆柱形滚筒轴承被广泛用于各种需要精准,速度和冲击阻力的工业机械. 此外,全球汽车产量的上升也推动了对圆柱式滚筒轴承的需求。 然而,替代品的可得性和不稳定的原材料成本会阻碍市场增长。 主要行为者可以探索发展中区域的机会,以及可再生能源等需要强力轴承的行业的机会。 总的来说,由于各行业的应用不断增长,市场已准备好稳定增长。

圆柱形滚轮轴承市场 趋势

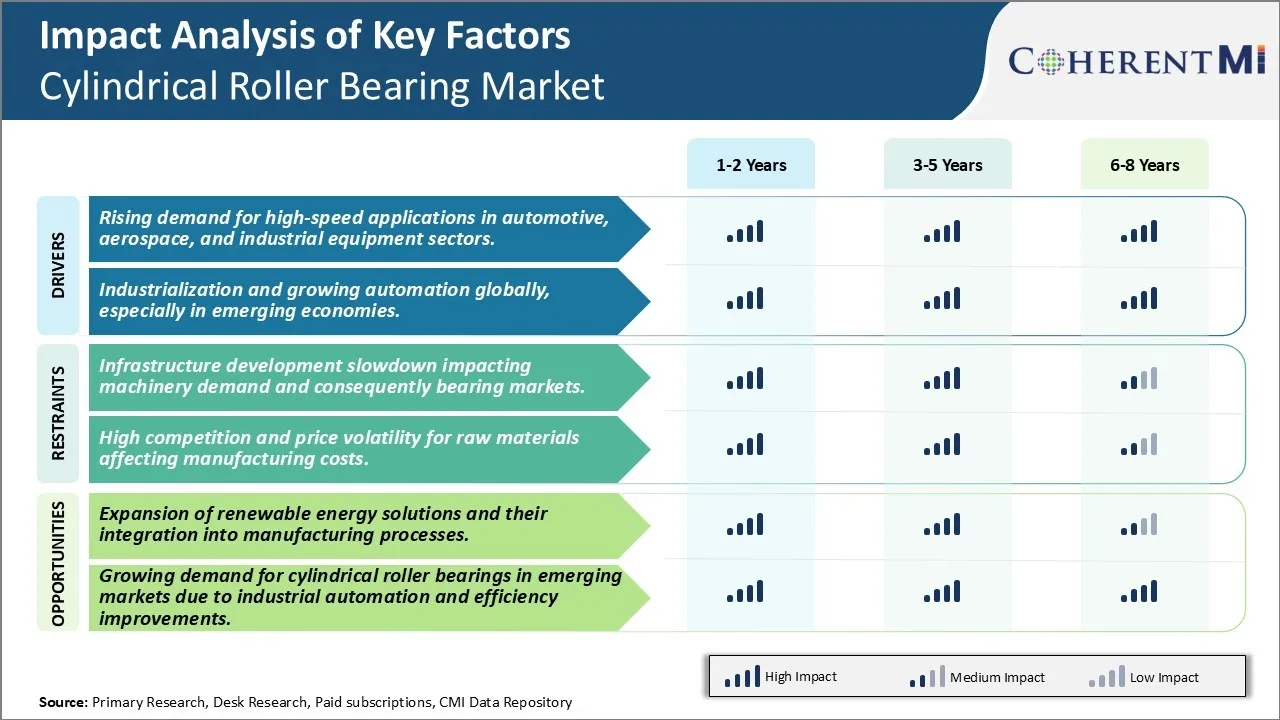

市场驱动力 - 对汽车、航空航天和工业设备部门高规格应用的需求增加

圆柱式滚轴轴轴承市场正受到对轴承不断增长的需求的积极影响,这些轴承能够承受各种应用产生的高旋转速度和负载. 与其它轴承类型相比,圆柱滚筒轴承的负载能力较高,能够有效处理射线力. 这使得它们非常适合汽车、航空航天和工业机械方面的大量高速设备。

在汽车工业中,圆柱式滚筒轴承被广泛用于连接杆,凸轮,转向架系统,传动,差分等发动机组件中. 由于汽车制造商更注重燃料效率和性能,对轻量级但强大的发动机的需求日益增加。 这正在推动先进发动机技术的发展,其特点是压缩率更高,循环零件在增加的RPM中运行。 由于圆柱滚筒轴承能够承受现代发动机产生的高运行速度和温度,因此其采用稳步增长. 此外,车辆电气化也增加了增长。 电力机车驱动电动机和变速箱需要采用重载轴承处理高转速.

航空航天工业是另一个利用各种机体和发动机部件的圆柱滚筒轴承的主要最终用户。 由于飞机制造者设计出新的飞机模型,带有先进的发动机和系统,能提供更好的燃油效率,速度和可靠性,因此更加强调耐用轴承.

工业机械从机具,泵,压缩机到电动机等也驱动采用圆柱式滚筒轴承. 现代工业设备有更加精确和紧凑的设计,要求轴承携带更多的负载而不增加尺寸.

市场驱动力----工业化和增长自动化鼓励工业增长

自动化对于通过优化流程寻求更高的生产力和质量的行业来说,已变得至关重要。 特别是正在迅速工业化的新兴经济体,自动化问题日益受到重视。 有助于在更大范围内实施自动化系统的一个关键因素是,提供坚固和持久的圆柱式滚筒轴承。

在自动化生产线上,圆柱式滚筒轴承是不可或缺的,因为这些轴承使各种机器人臂,传动系统,马达,和机器零件能够长时间无缝运行,而不会发生故障. 它们处理射线和轴负载的多面性使它们适合各种工业机器人和自动化应用。 圆柱滚筒轴承的精度,耐腐蚀性,载荷能力提供不间断的机械操作,对于实现线路效率最大化至关重要. 其可靠性可降低停工时间成本,并有助于各行业实现持续生产目标.

随着发展中国家通过工业化方案和激励措施促进当地制造业的发展,建立新的自动化工厂得到了极大的推动。 汽车、电子、半导体等工业目睹了新兴市场的扩展,同时对工业设备和圆柱滚筒轴承产生了需求。 各国政府促进工业自动化,以提高生产能力和质量标准,使之与全球水平相当。 这有助于安装由坚固的轴承部件提供动力的先进自动化生产技术。

甚至基础设施开发项目也使用重型机械,使各种任务自动化。 道路、港口、建筑物和公用网络的建设扩大了对挖掘机、起重机、需要溢价圆柱滚筒轴承的隧道滚筒的依赖。 其延长的寿命满足在崎岖的室外条件下运行的机械的严格性能需要。 因此,不断增加的全球基础设施投资使圆柱式滚筒轴承业受益。

市场挑战 - 基础设施发展减缓对机械需求的影响,并因此影响市场

圆柱滚筒轴承市场目前面临的主要挑战之一是全球基础设施发展活动放缓。 在过去几年里,许多国家由于各种经济和政治原因减少了基础设施开支。 这对建筑和土动机械的需求产生了负面影响,这些机械是圆柱滚筒轴承的主要消费者。 因此,承载业机械销售疲软,特别是在建筑设备、采矿卡车、重型起重机等部门的应用。 此外,当前的全球贸易冲突使许多原设备制造商对资本支出和扩建计划十分警惕。 由于其终端产品的订单减少,机械OEM在采购轴承和其他部件时也较为保守. 具有影响力的市场参与者需要密切监测基础设施和机械部门的这种需求下降,并相应调整其生产和能力扩展计划,以避免急剧调整。

市场机会:扩大可再生能源解决办法并将其纳入制造过程

为圆柱滚筒轴承市场提供重要机会的一个关键领域是可再生能源日益被采用。 由于日益强调降低碳足迹和过渡到更清洁的燃料来源,许多国家正在积极支持太阳能和风力发电能力的增长。 这导致在世界范围内对风力涡轮机和太阳能板制造部门进行大量投资和扩展活动。 随着可再生能源技术进一步融入工业进程,它刺激了对配备先进轴承的新机械的需求。 许多原始设备制造商正在创新其产品组合,以满足可再生能源设备应用的特殊需要。 这为圆柱滚筒搭载生产者提供了渗透新产品部分和客户的渠道。 通过开发专门处理可再生系统运行条件和负荷的轴承,它们可以获得机会,加强在新兴工业中的地位。

关键参与者采用的关键制胜策略 圆柱形滚轮轴承市场

产品创新和技术 进步 :

- 主要公司正在对研发进行大量投资,以开发具有增强载荷能力、耐久性和运营效率的高性能轴承。 这包括将智能技术和IOT结合起来,以便能够预测维修、实时监测以及汽车、工业机械和可再生能源等关键应用的操作效率。

- 通过增强材料和设计,公司还注重耐热和耐磨轴承,以满足高速和重型应用的需求.

地理扩展和市场多样化:

- 公司正在扩展到亚太、拉丁美洲和东欧的新兴市场,在那里,迅速的工业化和汽车制造对圆柱式滚筒轴承产生了强劲的需求。 在这些区域建立生产设施和销售网络,使参与者能够有效地为当地市场服务,降低物流成本。

- 一些公司还针对可再生能源和航空航天等新的应用领域,使其客户基础多样化,因为专门圆柱轴承对可靠性和性能至关重要。

战略伙伴关系与协作:

- 关键参与者正在汽车、航空航天和工业机械等部门与OEM和最终用户结成联盟,共同开发量身定制的轴承解决方案。 这些伙伴关系使它们能够更好地了解具体的应用要求,并提供定制产品,以应对独特的业务挑战。

- 合作还扩展到技术提供者,联合创新举措侧重于可持续性,如制定符合环境条例和可持续性目标的有利于生态的润滑剂备选方案和可再循环承载材料。

这些战略使公司能够在竞争日益激烈的全球市场中加强其市场地位,改善产品供应,并开拓新的增长领域。

分段分析 圆柱形滚轮轴承市场

透视 2024年按类型,单排圆柱式滚筒轴承 享受著名市场份额

按类型计算,由于工业应用广泛,2024年单排圆柱式滚筒轴承预计将贡献46.2%。 单排圆柱形滚筒轴承是最常用的滚筒轴承类型,因其简单多变. 它们适用于许多行业的各种轻度到中度载荷应用. 与双层或四层轴承相比,单层轴承的组件较少,使其更容易制造和维护. 它们的直截了当的建造也意味着它们对于共同用途更具成本效益。

驱动对单排轴承的高需求的一个关键因素是它们是否适合通用机械。 它们在工业发动机、风扇、泵和其他旋转设备中广泛使用,这些设备在线性运动或旋转运动中需要轻量级轴架的支持。 他们的负载能力满足了大多数轻到中型工业机器的要求. 此外,由于一般机械包含更自动化的功能,这些应用程序对单排轴承的需求继续增长.

通过应用的洞察力,汽车工业是由巨大需求驱动的快速增长

在汽车工业中,单排圆柱式滚筒轴承也广泛使用。 预计汽车工业在2024年将占54.3%。 它们通常用于发动机组件,引导系统,传输和轮子中枢等应用. 他们对摩擦和振动的抵抗使它们非常适合现代车辆中要求很高的操作条件. 较新型汽车车型中先进驾驶员援助和安全特性的普及,也促进了单排轴承的安装。 单排圆柱式滚筒轴承的多面性,成本效益和广泛的工业适用性使得这一段成为整个市场上收入最高的产生者. 随着整个制造设施和汽车生产自动化和复杂性的提高,对无麻烦、轻量级支持功能的需求预计将继续稳步增长。

附加见解 圆柱形滚轮轴承市场

由于汽车和重型机械部门的需求不断增长,圆柱滚筒轴承市场正在稳步增长,特别是在工业化地区。 轴承在包括EVs和先进机械在内的高速应用中发挥着至关重要的作用,其中耐久性和效率至关重要。 亚太区域,特别是中国和印度,由于工业的迅速增长,市场处于领先地位,而北美将受到汽车和航空航天技术进步的推动而迅速增长。 以负荷管理、耐久性和环境效率为重点的高性能轴承创新正在进一步推动市场。 然而,原材料价格波动和假冒产品等挑战影响到盈利能力,使市场具有高度竞争力。

竞争概览 圆柱形滚轮轴承市场

在环形卷轴市场运营的主要角色包括JTEKT印度有限公司,NTN公司,SKF,Schaeffler印度有限公司,国家工程工业有限公司(NEI),NRB轴承有限公司,Menon轴承有限公司,MBP轴承有限公司,Kennametal印度有限公司和宝马摩托拉德.

圆柱形滚轮轴承市场 领导者

- JTEKT 印度有限公司

- NTN公司

- SKF( 韩国足协)

- 沙夫勒印度有限公司

- 国家工程工业有限公司(NEI)

圆柱形滚轮轴承市场 - 竞争对手

圆柱形滚轮轴承市场

(主要参与者主导)

(竞争激烈,参与者众多。)

最新发展 圆柱形滚轮轴承市场

- 2023年11月,Kennametal India Limited的WIDMA Machining Solutions Group推出VT850,这是一款二轴垂直转向架,提高了大型组件的机械化效率.

- 2023年9月,宝马 摩托拉德公司引入了2024BMW R 1300 GS,为汽车部门拓展了其高性能的报价.

圆柱形滚轮轴承市场 细分

- 按类型

- 单排圆柱式滚筒轴承

- 双排圆柱式滚筒轴承

- 四行圆柱形滚筒轴承

- 其他人员

- 通过应用程序

- 汽车

- 机械

- 其他人员

您想要了解购买选项吗?本报告的各个部分?

常见问题 :

圆柱形卷轴市场有多大?

全球圆柱形滚轮轴承市场估计价值25.8美元。 Bn在2024年,预计达到48.4美元。 Bn 2031年时.

圆柱形卷轴市场CAGR是什么?

环形滚筒轴承市场的CAGR预计从2024年到2031年占8.1%.

驱动圆柱形卷轴式市场增长的主要因素是什么?

汽车、航空航天和工业设备部门以及工业化和全球自动化不断增长对高速应用的需求不断增长,特别是在新兴经济体,是推动环形卷轴市场的主要因素。

哪些关键因素阻碍了圆柱形卷轴市场的发展?

基础设施的发展放缓影响机械需求,进而影响市场,以及影响制造业成本的原材料的高竞争和价格波动,是阻碍圆柱形卷轴市场增长的主要因素。

圆柱形卷轴市场中哪一种是领先型号?

单排圆柱形滚筒 轴承是最主要的类型段.

在圆柱形卷轴市场运营的主要角色是哪些?

JTEKT India Limited, NTN Corporation, SKF, Schaeffler India Limited, National Engineering Industries Ltd (NEI), NRB轴承有限公司, Menon轴承有限公司, MBP轴承有限公司, Kennametal India Limited, BMW 摩托拉德是主要角色.