Insulated Packaging Market Size - Analysis

Market Size in USD Bn

CAGR7.3%

| Study Period | 2025-2032 |

| Base Year of Estimation | 2024 |

| CAGR | 7.3% |

| Market Concentration | Medium |

| Major Players | Post DHL, Sofrigam, Winpak, E.I. Du Pont De Nemours and Co., Amcor Limited and Among Others |

please let us know !

Insulated Packaging Market Trends

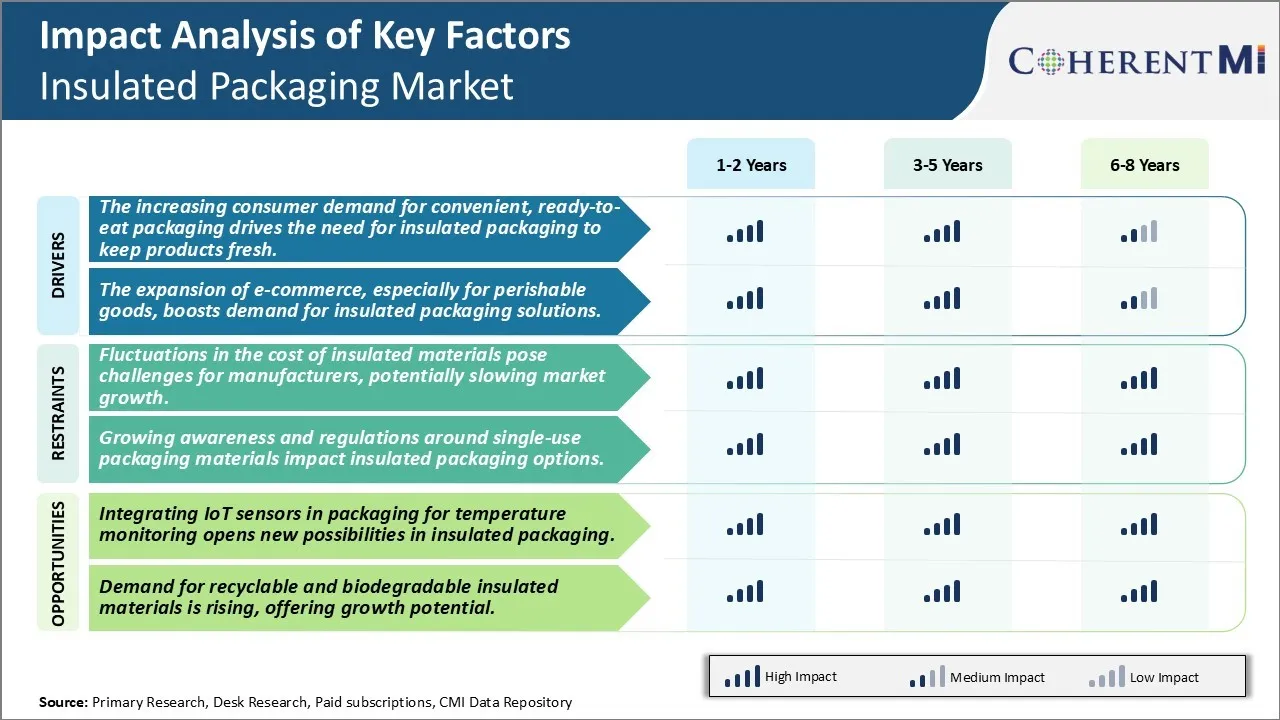

With increasingly hectic lifestyles, consumers are constantly looking for convenient packaging solutions that can be easily accessed and consumed on-the-go. There has been a notable rise in demand for ready-to-eat and prepared meals over the past decade owing to the lack of time for food preparation at home. As customers seek maximum convenience, packaged food products that provide portion-controlled servings and require minimal or no preparation have gained immense popularity. However, prepared foods are highly perishable in nature and require proper temperature-controlled packaging to maintain freshness and edibility. This has spurred the need for insulated packaging materials and solutions that can withstand fluctuations in temperature while transporting and storing ready-to-eat goods.

Moreover, as lifestyles become more mobile, there is rising demand for portable snack packs and smaller on-the-go meal kits that can be easily carried and consumed anywhere. Insulated packaging formats like coolers, sleeves and containers allow the distribution of pre-portioned, fresh mini-meals for travelers, commuters and outdoor enthusiasts. Their ability to maintain an optimal internal temperature for over 8-12 hours without refrigeration expands the scope for convenient consumption even outside of typical mealtimes. The growth in demand for ready meals and snacks thus propels the insulated packaging industry to innovate compact, high-performance solutions for situational eating.

Market Driver - The Expansion of E-Commerce, Especially for Perishable Goods, Boosts Demand for Insulated Packaging Solutions

Specialized insulated mailers, cartons and boxes have thus become indispensable for long-distance refrigerated transport of perishables via e-commerce. Advanced designs with insulation layers, cushioning and temperature tracking capabilities protect shipments from environmental conditions while providing transparency. Several platforms also offer temperature-controlled packaging, often paired with reusable ice packs, gel packs or chemical activated coolants to maintain a cool interior environment through multiple deliveries per day. Such innovations boost consumer confidence in purchasing fresh items online by minimizing risks of degradation during deliveries.

Market Challenge - Fluctuations in The Cost of Insulated Materials Pose Challenges for Manufacturers, Potentially Slowing Market Growth

Integrating IoT sensors in packaging for temperature monitoring opens new possibilities in insulated packaging. By embedding sensors that can track temperature conditions during transit both internally and on the exterior packaging surface, critical information on temperature compliance can be gathered. IoT connectivity built into the packaging then enables this data to be transmitted in real-time to all relevant stakeholders. This allows shippers and end customers to proactively monitor shipments and ensure product safety and quality are maintained according to regulatory and industry standards. It also eliminates the need for resource-intensive manual temperature data logging during transportation. Manufacturers can leverage such smart active packaging solutions to unlock valuable use cases across industries including healthcare, pharmaceuticals, food and beverage. This translates to immense market potential and better margins driven by value additions. By offering transparency and accountability, IoT-enabled insulated packaging assists in building long term customer loyalty and trust as well. This emerging technology presents a pivotal opportunity for innovators to gain first-mover advantage and accelerating revenue growth in the coming years.

Key winning strategies adopted by key players of Insulated Packaging Market

- Market Consolidation Through Mergers and Acquisitions: Several top players have pursued consolidation strategies to expand their product portfolio and market share.

- Focus on Sustainability and Eco-Friendly Materials: Given rising environmental concerns, leading players like Cold Chain Technologies, Davis Core & Pad, and Intelsius have focused on developing more sustainable insulated packaging solutions made from recycled or recyclable materials. For example, Cold Chain Technologies launched its advanced EcoPack insulated shipping container with >90% recycled content in 2020. Such sustainable packaging options have resonated well with environmentally conscious customers and provided these companies an edge in the growing green packaging market.

- Leveraging Advanced Technologies: Top players have invested in technologies like vacuum insulation panels (VIPs), phase change materials (PCMs), and smart sensors to develop high-performance yet cost-effective packaging products.

- Strategic Partnerships: Leading companies’ partner with logistics providers, pharma companies, food retailers and others to gain expertise as well as ensure seamless integration of insulated packaging solutions with the customers' supply chains.

Segmental Analysis of Insulated Packaging Market

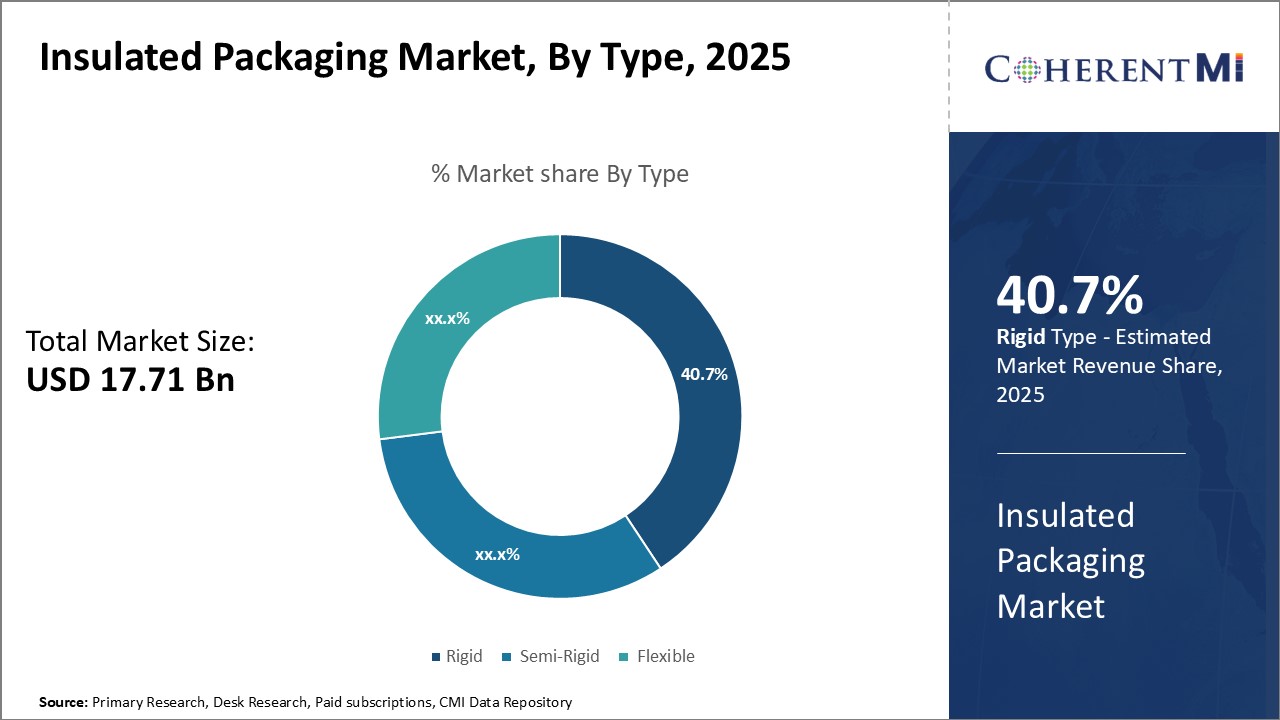

Insights, By Type, Rigid Packaging's Durability and Reusability Drive Highest Market Share

Additionally, rigid insulated packaging is highly reusable. Products shipped in sturdy rigid packages can be returned when empty. This restore and reuse philosophy allows multiple round trips, lowering overall packaging costs for suppliers. Reusability also promotes sustainability goals of companies. Certain rigid packages are designed for reuse up to 25 times before replacement. Their solid build quality supports repeated uses with minimal degradation. This reuse capability combined with durability makes rigid insulated packaging a preferred solution for industries shipping temperature regulated goods in bulk.

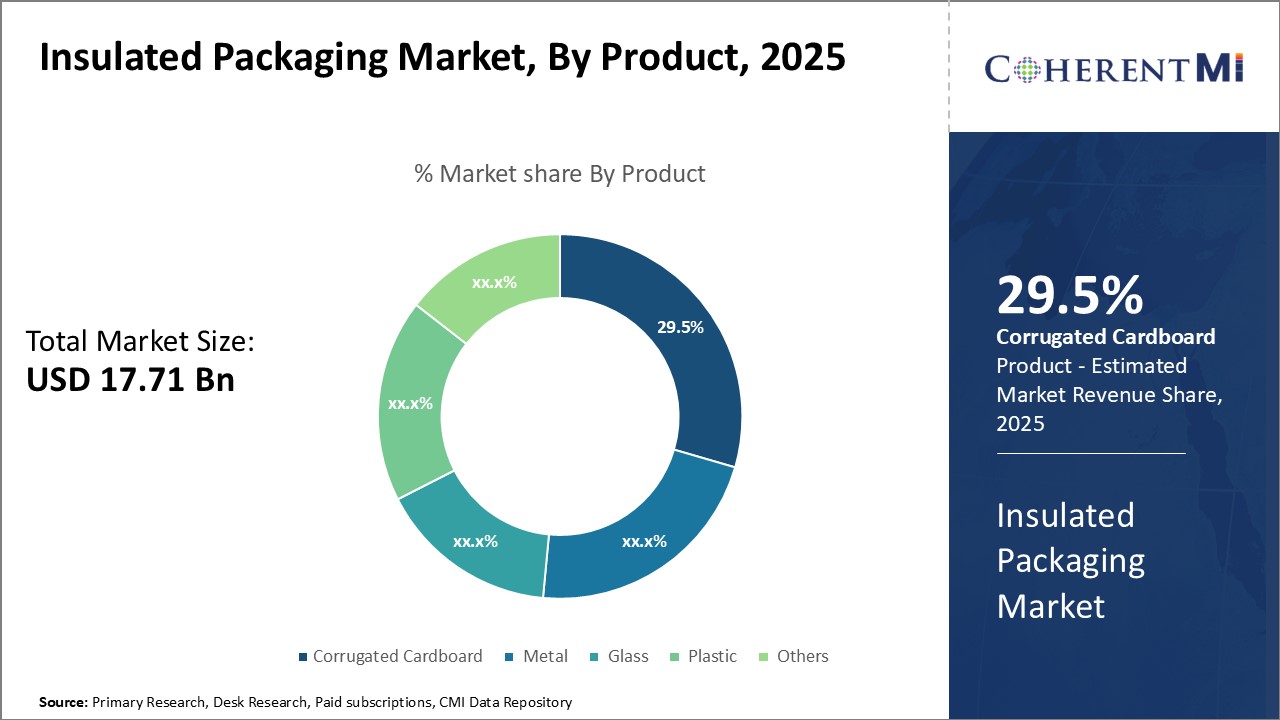

Insights, By Product, Corrugated Cardboard's Cost Effectiveness and Customizable Properties Drive Highest Market Share

Insights, By Product, Corrugated Cardboard's Cost Effectiveness and Customizable Properties Drive Highest Market Share

Corrugated cardboard packaging solutions are also highly customizable. Various production techniques allow modifying features like insulation types, cut outs, dimensions to suit specific product and application needs. This versatility in design and production helps customize packages as per customer requirements, providing niche solutions. Companies appreciate such tailor-made solutions that focus on their exact product handling needs.

By Application, Cosmetic contributes the highest share of the market owing to the industry's complex product handling temperature and hygiene needs. Cosmetic products are highly sensitive to temperature and contamination variations. Even minor fluctuations can impact product quality, safety, and effectiveness. Also, preserving the aesthetic appeal of cosmetic packaging during storage and transit is imperative.

Besides thermal and microbe protection, cosmetic-grade insulated packaging focuses on maintaining the visual attractiveness of stock-keeping units throughout the supply chain. Special multi-layered packaging structures and contamination-proof zip locks allow unscathed delivery of high-value cosmetic items to shelves. Such attributes matching stringent cosmetic industry needs fuel their widespread use across applications ranging from skincare to color cosmetics. Hence, Cosmetics contributes the highest share among application segments for insulated packaging market.

Additional Insights of Insulated Packaging Market

The insulated packaging market is increasingly essential due to shifts in consumer lifestyles, particularly with the growth of convenience food, e-commerce, and delivery services. The market’s growth is also fueled by the pharmaceutical industry’s need for temperature-controlled solutions, especially with increasing biologics and vaccine transport. High demand is observed in regions like Asia Pacific due to urbanization and rising disposable incomes, which lead to higher consumption of temperature-sensitive goods. As sustainability concerns rise, companies are focusing on recyclable materials and IoT-enabled “smart” packaging to enhance quality and meet eco-friendly regulations. In regions like North America, insulated packaging also supports a robust cold chain infrastructure for pharmaceuticals, with expected growth from 2024 to 2033.

Competitive overview of Insulated Packaging Market

The major players operating in the Insulated Packaging Market include Post DHL, Sofrigam, Winpak, E.I. Du Pont De Nemours and Co., Amcor Limited, Sonoco Products Company, Huhtamaki OYJ, Constantia Flexibles, Greiner Group, Innovia Films, Exeltainer, American Aerogel Corporation, Thermal Packaging Solutions, TemperPack and Insulated Products Corp.

Insulated Packaging Market Leaders

- Post DHL

- Sofrigam

- Winpak

- E.I. Du Pont De Nemours and Co.

- Amcor Limited

Insulated Packaging Market - Competitive Rivalry

Insulated Packaging Market

(Dominated by major players)

(Highly competitive with lots of players.)

Recent Developments in Insulated Packaging Market

- In June 2024, ProAmpac introduced ProActive Recyclable® FiberCool, an insulated recyclable bag for curbside use, targeting food delivery with eco-friendly, temperature-controlled packaging.

- In January 2024, Thermal Custom Packaging launched a grant contest to support first responders with insulated totes for medical supplies, showcasing their commitment to safety and innovative storage.

- In September 2023, Pluss Advanced Technologies released the Celsure® XL Pallet Shipper and VIP Multi-Use Parcel Shipper for pharmaceuticals, enhancing the safe, temperature-controlled transport of medicines.

Insulated Packaging Market Segmentation

- By Type

- Rigid

- Semi-Rigid

- Flexible

- By Product

- Corrugated Cardboard

- Metal

- Glass

- Plastic

- Others

- By Application

- Cosmetic

- Pharmaceutical

- Industrial

- Food & Beverages

- Others

Would you like to explore the option of buying individual sections of this report?

Shivam Bhutani has 6 years of experience in market research and strategy consulting. He is a Market Research Consultant with strong analytical background. He is currently an MBA candidate specializing in Business Analytics from BITS Pilani.

He is adept at navigating diverse roles from sales and marketing to research and strategy consulting. He excels in market estimation, competitive intelligence, pricing strategy, and primary research. He is skilled at analysing large datasets to provide precise insights, helping clients in achieving strategic transformation across various industries. He is skilled in leveraging data visualization techniques to drive innovation and enhance business processes.

Frequently Asked Questions :

How Big is the Insulated Packaging Market?

The Global Insulated Packaging Market is estimated to be valued at USD 17.71 Bn in 2025 and is expected to reach USD 29.00 Bn by 2032.

What will be the CAGR of the Insulated Packaging Market?

The CAGR of the Insulated Packaging Market is projected to be 7.1% from 2024 to 2031.

What are the major factors driving the Insulated Packaging Market growth?

The increasing consumer demand for convenient, ready-to-eat packaging drives the need for insulated packaging to keep products fresh and the expansion of e-commerce, especially for perishable goods, boosts demand for insulated packaging solutions are the major factors driving the Insulated Packaging Market.

What are the key factors hampering the growth of the Insulated Packaging Market?

The fluctuations in the cost of insulated materials pose challenges for manufacturers, potentially slowing market growth. and growing awareness and regulations around single-use packaging materials impact insulated packaging options are the major factors hampering the growth of the Insulated Packaging Market.

Which is the leading Type in the Insulated Packaging Market?

Rigid Packaging is the leading Type.

Which are the major players operating in the Insulated Packaging Market?

Post DHL, Sofrigam, Winpak, E.I. Du Pont De Nemours and Co., Amcor Limited, Sonoco Products Company, Huhtamaki OYJ, Constantia Flexibles, Greiner Group, Innovia Films, Exeltainer, American Aerogel Corporation, Thermal Packaging Solutions, TemperPack, Insulated Products Corp. are the major players.