Deodorization System Market Size - Analysis

The deodorization system market is expected to witness positive trends over the next few years. The rising consumption of packaged food products and increasing focus on food safety and quality are stimulating market growth. Additionally, advancements in technology to develop innovative solutions for effective removal of contaminants from edible oils are expected to create new opportunities for manufacturers.

Market Size in USD Bn

CAGR7.00%

| Study Period | 2025-2032 |

| Base Year of Estimation | 2024 |

| CAGR | 7.00% |

| Market Concentration | High |

| Major Players | Desmet Ballestra, Gianazza International S.p.A., Crown Iron Works, Alfa Laval AB, Zhengzhou Sunshine Machinery Co. Inc. and Among Others |

please let us know !

Deodorization System Market Trends

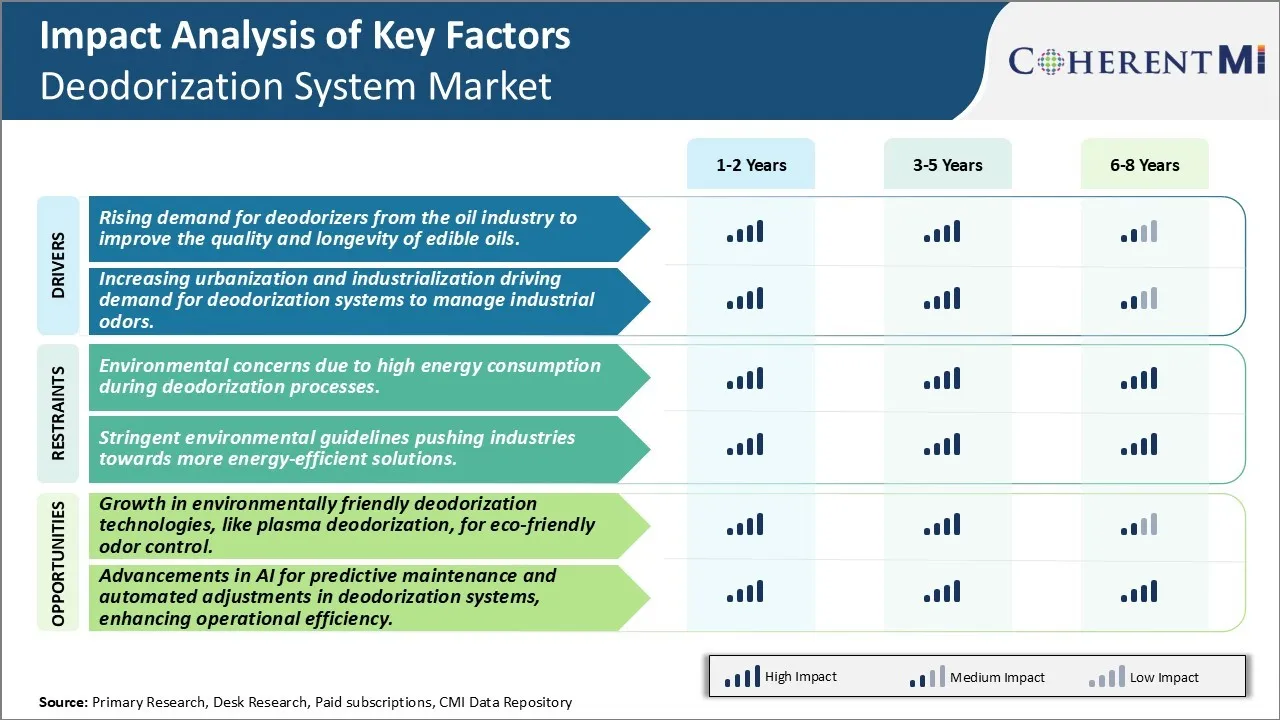

The market is witnessing significant growth on account of rising demand for deodorizers from the oil industry. Deodorization is an important process in the production of edible oils like soybean oil, sunflower oil, palm oil and others. Through the deodorization process, unwanted odors and tastes are removed from the crude oil, thereby improving its quality and making it fit for human consumption.

Modern consumers are more discerning about the purity, taste and smell of the food products they consume. Any presence of off-odors in edible oils can negatively impact their sale. Moreover, stringent food safety regulations around the world mandate that edible oils must be free of contamination and impart perfect sensory characteristics. This has pushed oil producers to invest more in robust deodorization infrastructure to ensure the oils manufactured by them fully comply with standards.

Rapid urbanization and industrial expansion worldwide have been crucial drivers for the Global Deodorization System Market. As more people migrate to cities for employment and livelihood opportunities, urban centers are burgeoning tremendously. However, large-scale urban and industrial activities also result in greater emission of odorous gases, fumes and smells from various sources such as factories, landfills, sewage treatment, and oil refineries.

Against this backdrop, industrial facilities and municipalities are compelled to adopt effective deodorization systems. Technologies such as biofiltration, thermal or catalytic oxidation help capture and neutralize odorous gases at the source itself before they are released. Some plants also utilize scrubbers that use alkaline solutions to dissolve odorous molecules. With urban and industrial development proceeding rapidly across major regions, the need for advanced odor control mechanisms has becoming increasingly indispensable. Governments too are mandating stricter emission standards, boosting investments in sophisticated deodorization solutions.

One of the key challenges currently faced by the deodorization system market is growing environmental concerns due to high energy consumption during traditional deodorization processes. Conventional deodorization techniques like steam distillation require heating oil to very high temperatures of around 200-300°C under vacuum to remove undesirable odor components. This leads to significant usage of fossil fuels and thereby high carbon footprint. It is estimated that deodorization can account for over 15% of total energy usage in vegetable oil refining. With rising climate change awareness, industry stakeholders and regulators are pressing for more sustainable odor removal solutions. Furthermore, strict environmental regulations around the world aim to minimize greenhouse gas emissions from manufacturing facilities. The energy intensive nature of common deodorization methods may discourage their long-term use. Solutions with reduced heat and power requirements need to be adopted to meet sustainability targets and lower environmental impact. Innovation in resource-efficient deodorization technologies is critical for future growth in this industry.

Market Opportunity - Growth in Environmentally Friendly Deodorization Technologies Like Plasma Deodorization for Eco-Friendly Odor Control

Key winning strategies adopted by key players of Deodorization System Market

Focus on innovation through R&D- One of the main strategies followed by market leaders like Alfa Laval, Desmet Ballestra, and Crown Iron Works is heavy investment in R&D to develop innovative deodorization systems. For example, in 2018 Alfa Laval launched the Alfa Laval Additav AC system which uses advanced processing technology to remove unpleasant tastes and odors from edible oils while retaining more beneficial components. Their R&D efforts helped reduce processing time by 30% compared to conventional systems.

Total Solution Provider and After-Sales Support- Market players like Crown Iron Works position themselves as a one-stop-solution offering integrated solutions beyond equipment. They provide engineering, installation, commissioning and long-term maintenance services.

Segmental Analysis of Deodorization System Market

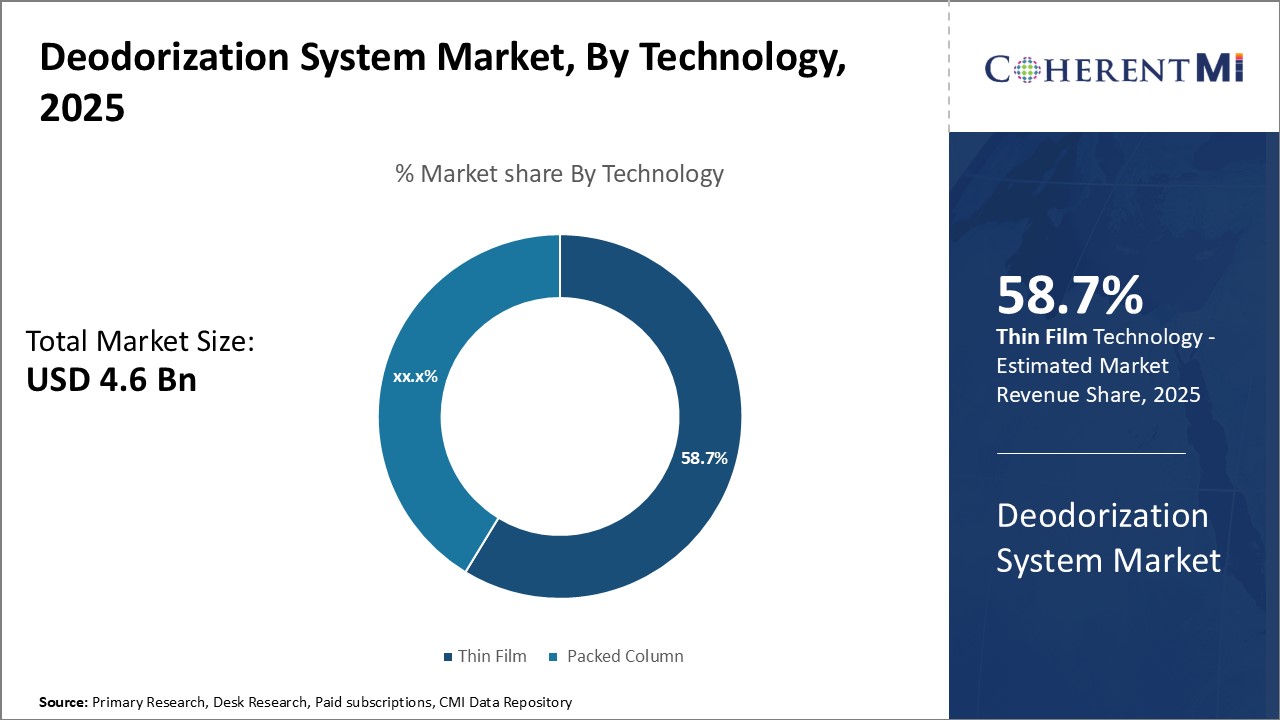

Insights, By Technology, Cost Efficiency and Energy Savings Drive Adoption of Thin Film Deodorization Systems

The improved thermal efficiency of Thin Film directly results in substantial energy savings during operation. Recent innovations have made Thin Film technology even more cost effective, such as new wiping element designs that are simple to maintain and replace. Thin Film also produces better quality outputs with more consistent odor removal. These tangible cost and operational benefits have made Thin Film an attractive proposition for edible oil processors, driving its increased adoption worldwide.

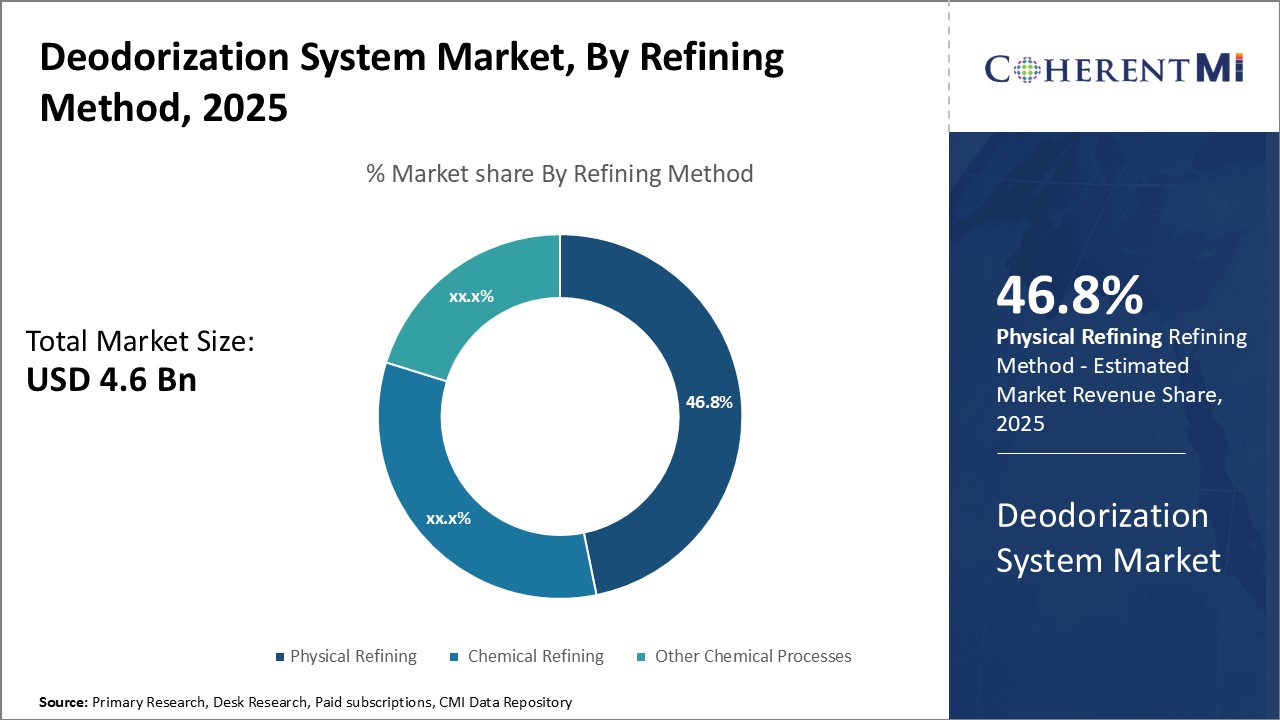

Insights, By Refining Method, Physical Refining is Preferred For its Mild Processing Conditions

Insights, By Refining Method, Physical Refining is Preferred For its Mild Processing Conditions

As consumer demand for minimally processed and natural foods has risen, physical refining has gained favor with edible oil processors. It allows producers to market their oils under non-GMO and organic certifications due to the absence of chemical exposure. Physical refining also incurs lower waste treatment costs as no hazardous byproducts are generated. These product quality and sustainability benefits provided by physical refining underpin its popularity over more intensive refining alternatives.

Insights, By Edible Oil, Abundant Supply and Versatile Uses Drive Soybean Oil Sales

Beyond its availability, soybean oil is also valued by food manufacturers for its neutral flavor profile and high smoke point, making it suitable for frying and baking applications. Soybean oil can replicate the textures of meat and dairy products, finding application in vegan substitutes that are in growing demand. It is also favored in industrial uses such as biodiesel production. The multi-faceted demand combined with stable supply chains have cemented soybean oil's prominence in the edible oil arena. This entrenched market position in turn supports soybean oil's leading share of capacity within deodorization systems.

Additional Insights of Deodorization System Market

The deodorization system market is gaining traction globally due to rising consumer awareness of hygiene, particularly in industrialized and urban areas. Essential for refining edible oils, deodorization improves the taste, texture, and quality of oils used in human consumption. Growth is driven by industrialization, with deodorization systems serving as crucial components in odor management across various settings, from food processing to large industrial facilities. AI advancements are enhancing efficiency, with predictive maintenance and real-time controls allowing for better odor management and air quality. Furthermore, environmentally friendly deodorization technologies are addressing sustainability concerns, particularly through plasma deodorization and biodegradable solutions, promoting eco-conscious odor control methods.

Competitive overview of Deodorization System Market

The major players operating in the Deodorization System Market include Desmet Ballestra, Gianazza International S.p.A., Crown Iron Works, Alfa Laval AB, Zhengzhou Sunshine Machinery Co. Inc. and DVC Process Technologists Pvt. Ltd.

Deodorization System Market Leaders

- Desmet Ballestra

- Gianazza International S.p.A.

- Crown Iron Works

- Alfa Laval AB

- Zhengzhou Sunshine Machinery Co. Inc.

Deodorization System Market - Competitive Rivalry

Deodorization System Market

(Dominated by major players)

(Highly competitive with lots of players.)

Recent Developments in Deodorization System Market

- In September 2024, Aquacycl launched SulfideFix, a product using natural bacteria to remove up to 99% of hydrogen sulfide in wastewater tanks, addressing odor and promoting sustainability in wastewater management.

- In August 2022, Rentokil North America introduced the GENIE Max odor management system, designed for large spaces, neutralizing foul smells and enhancing air care in indoor and outdoor settings.

Deodorization System Market Segmentation

- By Technology

- Thin Film

- Packed Column

- By Refining Method

- Physical Refining

- Chemical Refining

- Other Chemical Processes

- By Edible Oil

- Soybean Oil

- Olive Oil

- Peanut Oil

- Canola Oil

- By Operation

- Batch Deodorization Systems

- Semi-continuous System

- Continuous Deodorization Systems

Would you like to explore the option of buying individual sections of this report?

Sakshi Suryawanshi is a Research Consultant with 6 years of extensive experience in market research and consulting. She is proficient in market estimation, competitive analysis, and patent analysis. Sakshi excels in identifying market trends and evaluating competitive landscapes to provide actionable insights that drive strategic decision-making. Her expertise helps businesses navigate complex market dynamics and achieve their objectives effectively.

Frequently Asked Questions :

How Big is the Deodorization System Market?

The Global Deodorization System Market is estimated to be valued at USD 4.60 bn in 2025 and is expected to reach USD 7.39 bn by 2032.

What will be the CAGR of the Deodorization System Market?

The CAGR of the Deodorization System Market is projected to be 6.8% from 2024 to 2031.

What are the major factors driving the Deodorization System Market growth?

The rising demand for deodorizers from the oil industry to improve the quality and longevity of edible oils and increasing urbanization and industrialization drives demand for deodorization systems to manage industrial odors.

What are the key factors hampering the growth of the Deodorization System Market?

The environmental concerns due to high energy consumption during deodorization processes and stringent environmental guidelines pushing industries towards more energy-efficient solutions are the major factors hampering the growth of the Deodorization System Market.

Which is the leading Technology in the Deodorization System Market?

Thin Film is the leading Technology segment.

Which are the major players operating in the Deodorization System Market?

Desmet Ballestra, Gianazza International S.p.A., Crown Iron Works, Alfa Laval AB, Zhengzhou Sunshine Machinery Co. Inc., DVC Process Technologists Pvt. Ltd. are the major players.